Automatic packaging machine for concrete products for maritime work

A concrete product, automatic packaging machine technology, applied in the direction of packaging, transportation and packaging, packaging item types, etc., can solve the problems of inability to adjust the height of the packaging bag, inconvenient packaging, dust scattering, etc., to avoid pollution, facilitate packaging, The effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

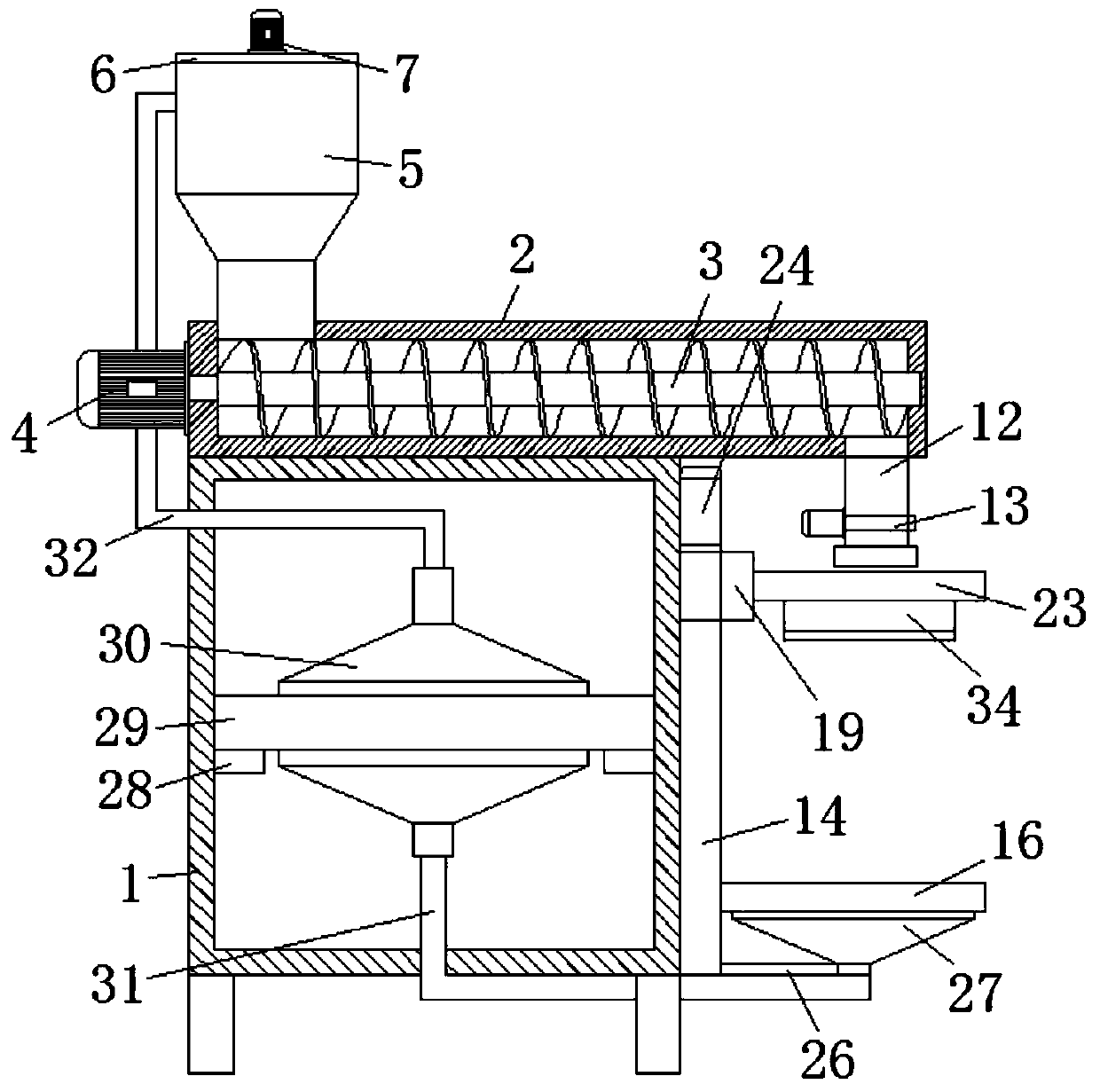

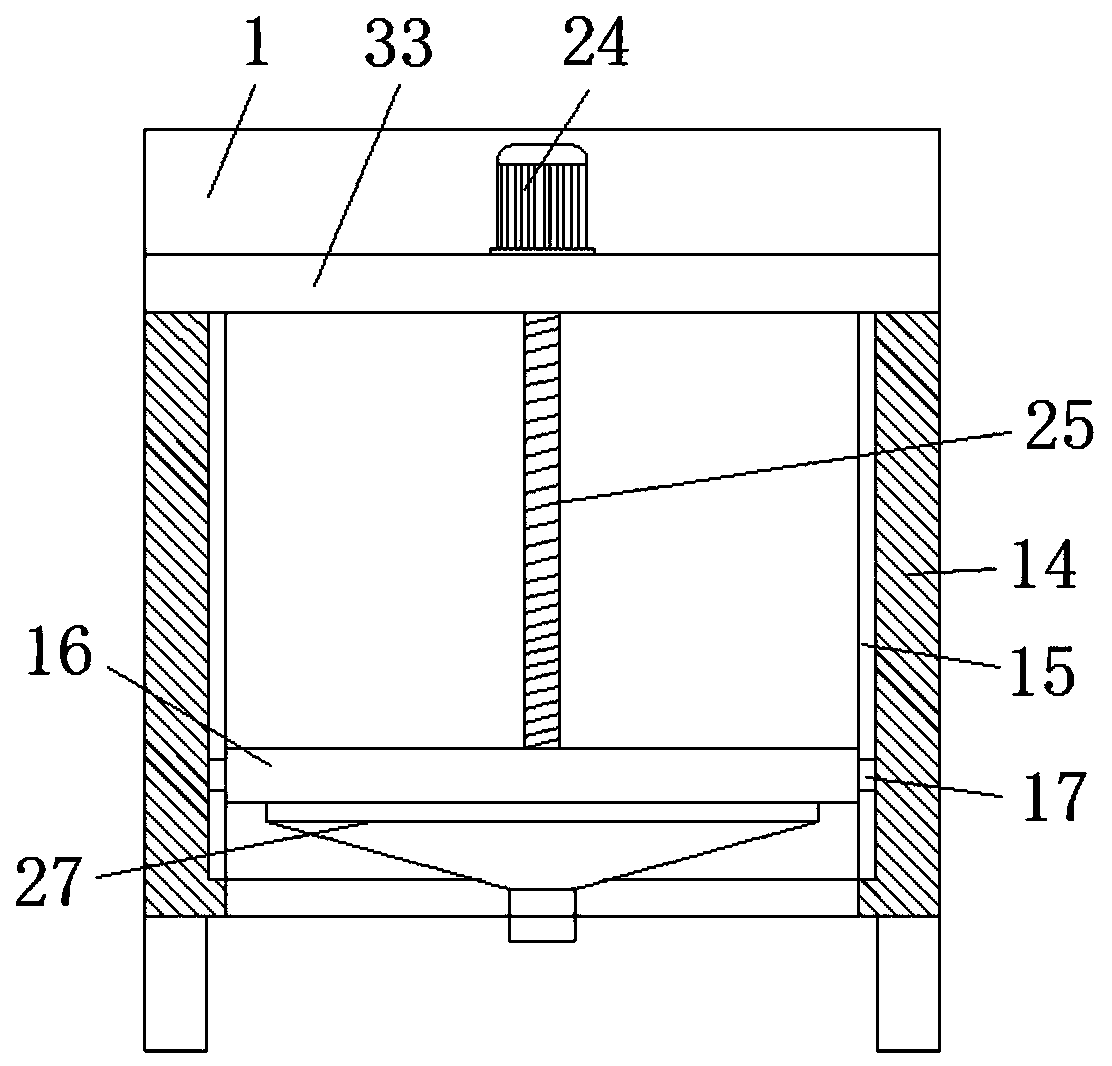

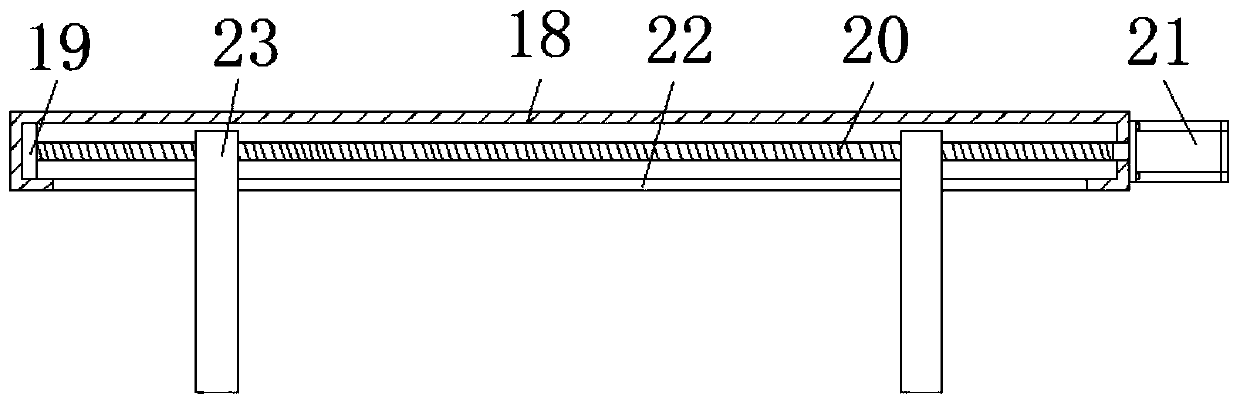

[0031] see Figure 1-5, this embodiment provides an automatic packaging machine for marine concrete products, including an installation box 1, the upper surface of the installation box 1 is fixedly connected with a delivery cylinder 2, and the inside of the delivery cylinder 2 is rotatably connected with a screw conveyor shaft 3, and the screw conveyor The middle part of the rear surface of the shaft 3 is fixedly connected with the first motor 4, and the output end of the first motor 4 traverses through the conveying cylinder 2 and is fixedly connected with one end of the screw conveying shaft 3, and the end of the conveying cylinder 2 away from the first motor 4 is lowered The surface is fixedly connected with a discharge cylinder 12, and the discharge cylinder 12 is connected with the conveying cylinder 2, and the upper surface of one end corresponding to the first motor 4 on the conveying cylinder 2 is fixedly connected with a hopper 5, and the hopper 5 is connected with the...

Embodiment 2

[0034] see Figure 1-5 On the basis of Embodiment 1, a further improvement has been made: the interior of the hopper 5 is fixedly connected with a reinforcement frame 8, the top of the hopper 5 is fixedly connected with a support frame 6, and the reinforcement frame 8 and the support frame 6 are rotatably connected with a rotating shaft 9 , and the rotating shaft 9 longitudinally runs through the reinforcing frame 8 and the supporting frame 6, the middle part of the upper surface of the supporting frame 6 is fixedly connected with the second motor 7, and the output end of the second motor 7 is fixedly connected with the top end of the rotating shaft 9, the rotating shaft The bottom end of 9 is fixedly connected with stirring paddle 11 below the reinforcement frame 8, and the stirring roller 10 is fixedly connected between the support frame 6 and the reinforcement frame 8 on the outer wall of the rotating shaft 9, and the stirring rollers 10 are annularly distributed. Control t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com