Underground coal mine directional long drilling recyclable fixed-point grouting device

A grouting device and long drilling technology, which is applied in directional drilling, earthwork drilling, wellbore/well parts, etc., can solve the problems of increased drilling cost, difficult drilling, complicated manufacturing process, etc., and achieve improved drilling efficiency. Improve construction efficiency, reduce drilling construction costs, and realize the effect of recycling and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] DRAWINGS Below, further detailed description of the technical solution of the present invention through specific embodiments.

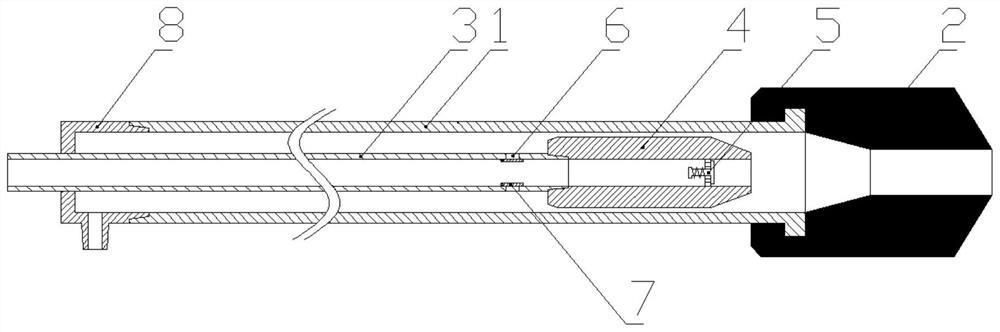

[0045] See figure 1 A coal mine borehole retrievable directional length grouting pointing device, a large-diameter drill pipe 1, the rubber plug 2, a small diameter drill rod 3, a metal plug 4, the water will bypass the check valve 8 and the 5 composition.

[0046] Large-diameter drill of the present embodiment is selected to be within the level of formula 1, i.e. flat large-diameter drill pipe; small diameter drill may be chosen to the level of formula 3, i.e. the level of the small-diameter drill pipe.

[0047] The rubber stopper 2 and a metal plug provided with a through-hole 4, the large-diameter drill pipe 1 is slightly larger than the inner diameter of the outer diameter of the plug 4 to the metal, the metal is slightly larger than the outer diameter of plug 4 2 the inner diameter of the rubber stopper, the said large-diameter rod with a rubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com