Rapid cooling device and cooling method for furnace lining

A rapid cooling and furnace lining technology, applied in the direction of furnace cooling device, etc., can solve the problems of poor cooling effect, complex structure, inconvenient operation, etc., achieve rapid cooling, save water resources, and realize the effect of recycling and reciprocating utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

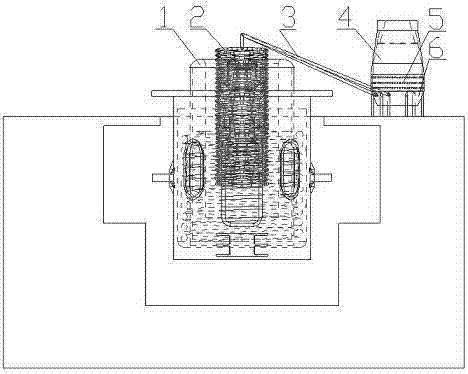

[0010] Embodiment 1: with reference to attached figure 1 . A furnace lining rapid cooling device, which includes a furnace lining 1, the furnace lining has a built-in heat absorbing ring 2 composed of multiple turns of water-cooled coils, the water inlet of the heat absorbing ring 2 communicates with the outlet of the water cooling recovery tower 4 through a water inlet pipe 3, and the water cooling The inlet of the recovery tower 4 communicates with the outlet of the heat absorbing ring 2 through the return pipe. The bottom 5 in the water cooling recovery tower 4 is equipped with a centrifugal impeller and driven by a motor. The body of the water cooling recovery tower 4 is provided with a plurality of air guide holes 6 .

Embodiment 2

[0011] Example 2: On the basis of Example 1, a method for quickly cooling the furnace lining, when the furnace lining 1 needs to be cooled, put the heat absorbing ring 2 into the furnace lining 1 and the upper part of the heat absorbing ring 2 is higher than the furnace lining mouth, and the cooling water is recovered The cooling water in the tower 4 flows into the heat-absorbing ring 2 through the water inlet pipe, and when it flows through the heat-absorbing ring 2, it absorbs the heat in the furnace lining and then enters the cooling water recovery tower 4 through the return pipe. Driven by the motor, the water-leaving impeller will return the water that flows back to the cooling water recovery tower 4 to centrifugal atomization and cooling in the tower, and then supply the heat-absorbing ring 2 through the water inlet pipe to absorb heat again, and circulate like this until the furnace lining cools down to the required temperature .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com