Fireproof sealing depth control device

A technology of depth control and fireproof sealing, which is applied in the direction of cable entry sealing device, etc., can solve the problems of unqualified fireproof sealing, and achieve the effect of saving construction time, saving installation time and maintenance time, and increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

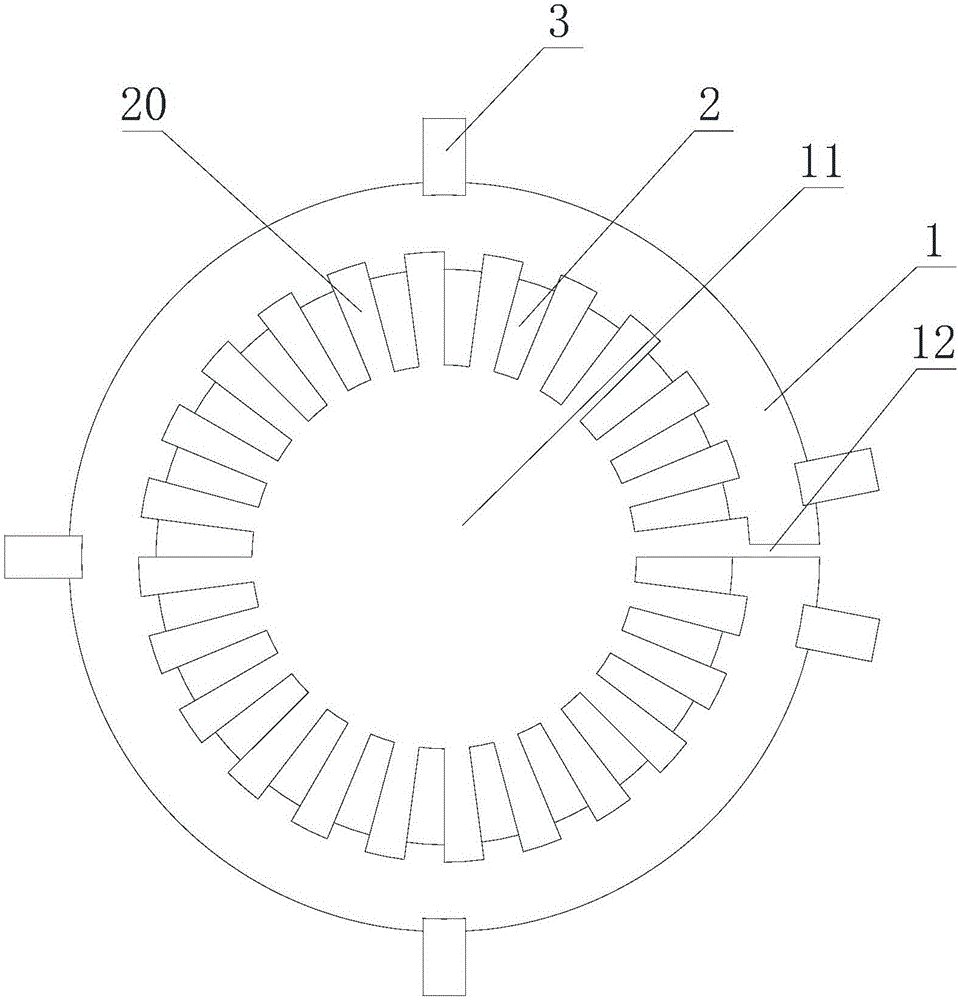

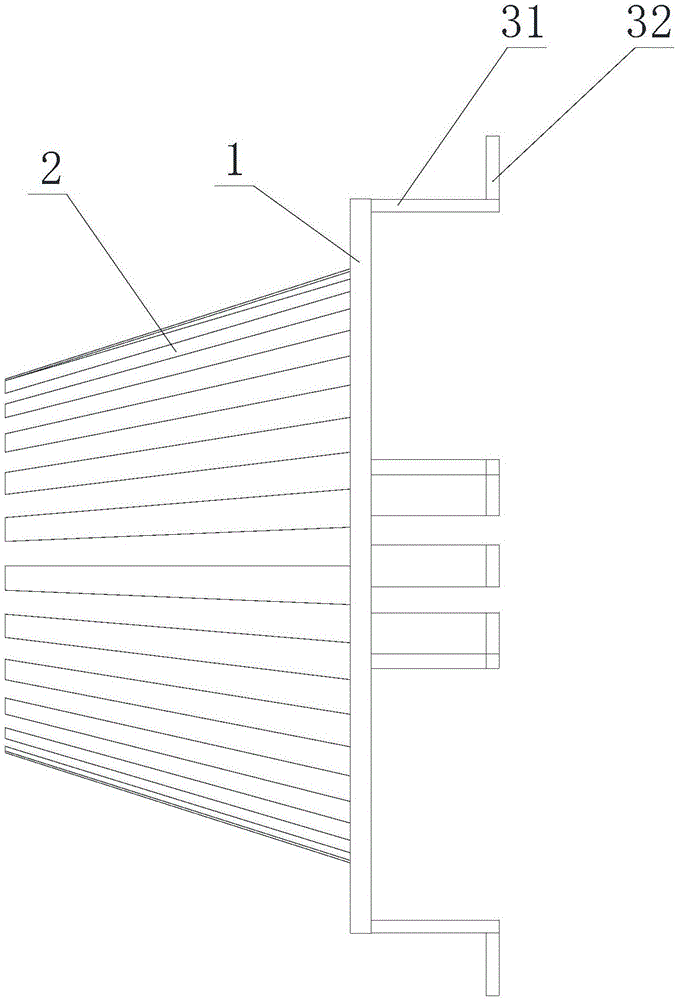

[0021] Such as figure 1 , figure 2 As shown, the fire prevention plugging depth control device includes a supporting piece 1, the middle part of the supporting piece 1 is provided with a through hole 11 for the cable to pass through, and the supporting piece 1 is provided with an opening 12 communicating with the through hole 11, supporting The sheet 1 is provided with a holding hoop 2 for holding the cable tightly, and the holding hoop 2 is provided with a space 20 filled with fireproof blocking material, and the supporting sheet 1 is provided with a fixing device for clamping the supporting sheet 1 on the protective tube. Sheet 3; supporting sheet 1, holding hoop 2 and fixing sheet 3 are all made of the following components: polycarbonate 85.2%, glass fiber 12.3%, toughening agent 0.55%, titanium dioxide 0.46%, high-temperature color powder 0.32%, anti-ultraviolet additive 0.37%, anti-sunlight agent 0.3%, flame retardant 0.5%.

[0022] The hoop 2 includes multiple hoop pi...

Embodiment 2

[0024] As in the first embodiment of the fire prevention blockage depth control device, this embodiment has the following differences: the supporting sheet 1, the holding hoop 2 and the fixing sheet 3 are all prepared from the following components: polycarbonate 87.6% , glass fiber 11.05%, toughening agent 0.34%, titanium dioxide 0.23%, high temperature color powder 0.15%, anti-ultraviolet additive 0.22%, anti-sunshine agent 0.17%, flame retardant 0.24%.

Embodiment 3

[0026] As described in Embodiment 1, the fire prevention blockage depth control device has the following differences: the supporting piece 1, the holding hoop 2 and the fixing piece 3 are all prepared from the following components: polycarbonate 90.3% , Glass fiber 9.7%.

[0027] When in use, the main material is formed by mixing polycarbonate and glass fiber, and then according to different installation environments and use environments, tougheners, titanium dioxide, high-temperature color powder, anti-ultraviolet additives, anti-sunshine agents, Flame retardant, according to the different types of cables, adjust the opening 12 so that the cables are installed and fixed in the through holes 11, and the cables are tightly held on the supporting piece 1 through the clamping hoop 2, and then the supporting piece 1 is clamped through the fixing piece 3 Connect it to the protective pipe, and finally fill the space 20 provided in the holding hoop 2 with the fireproof blocking mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com