Recovering device for waste 3D printing consumables

A technology of waste recycling and 3D printing, which is applied in the direction of additive processing, etc., can solve problems such as pollution and unrecyclable environment, and achieve the effect of reducing costs and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

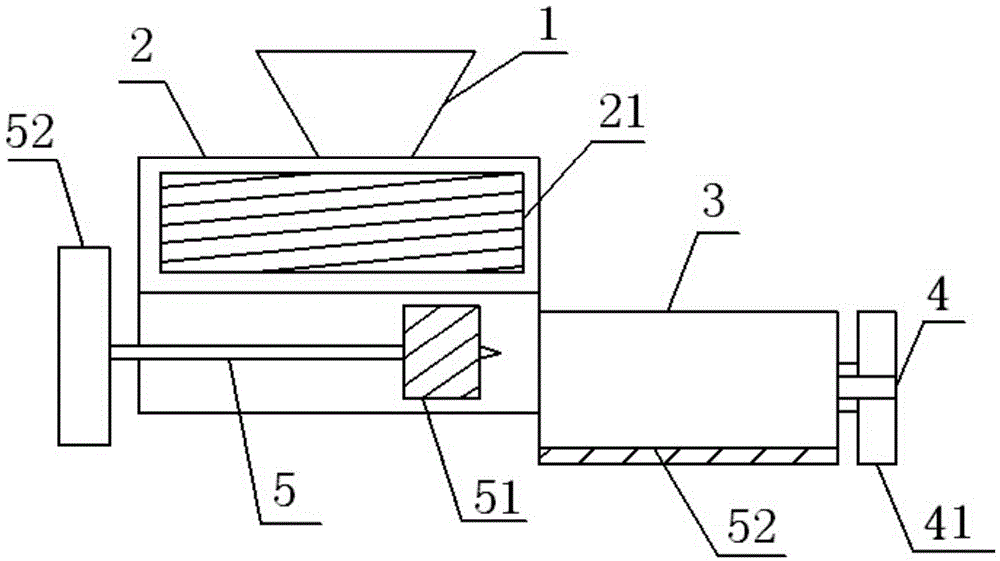

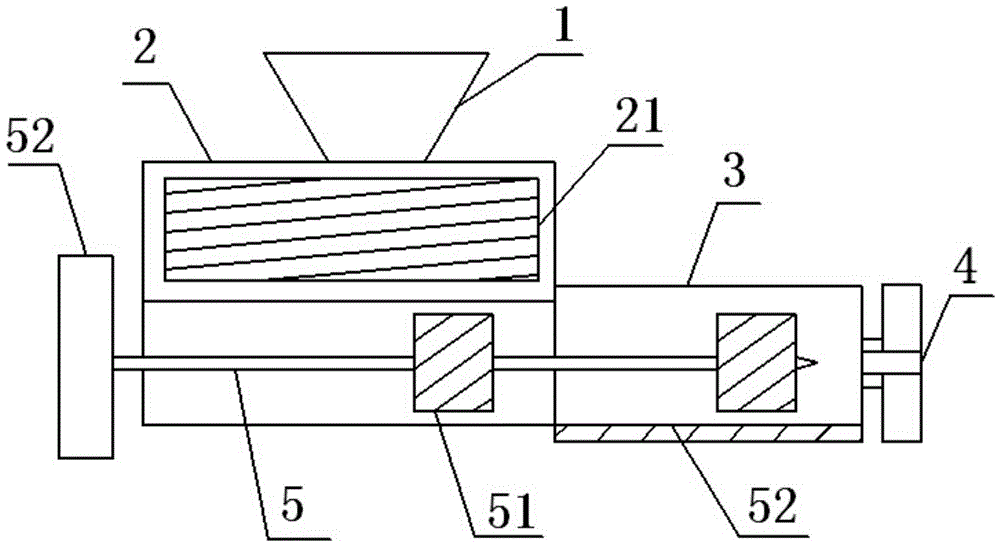

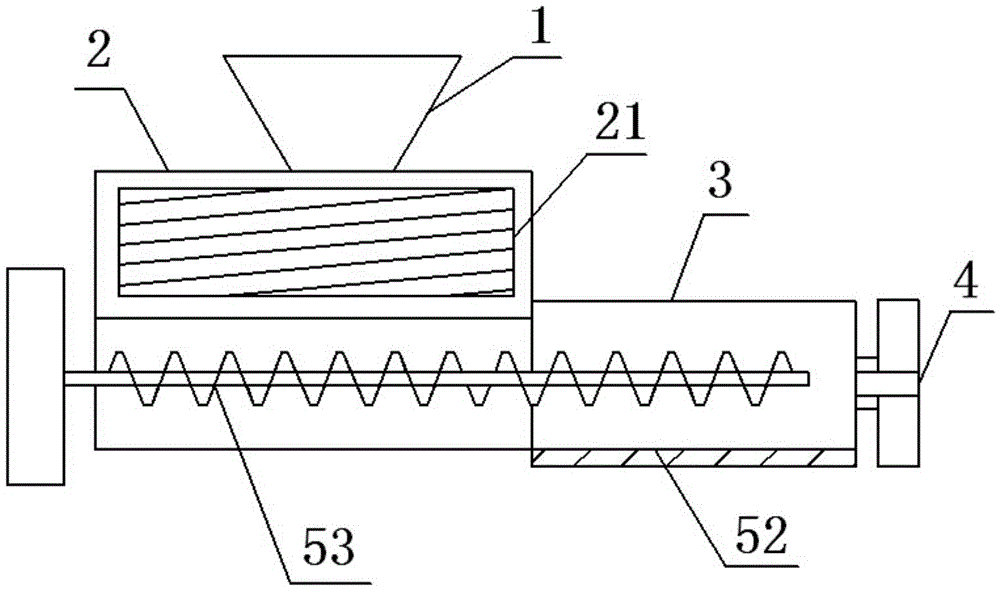

[0017] combine figure 1 , an embodiment of the present invention. A 3D printing consumable waste recovery device, comprising a feed port 1, a crushing chamber 2 connected to the feed port, the crushing chamber is provided with a pulverizer 21 inside, and a heating chamber 3 is provided outside, and the heating chamber is opened to recycle waste Outlet 4 for output after thermal melting. In this embodiment, the crushing chamber is provided with a conveying assembly 5 for conveying the crushed waste to the heating chamber. In this embodiment, the conveying assembly is fixed below the crushing chamber, and the crushed waste particles fall down and enter the heating chamber driven by the conveying assembly, where the heater 31 in the heating chamber heats them into a molten state. The new waste is output under pressure, and the heating chamber is lower than the crushing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com