Belt replacing method for coal mine belt conveyors

A technology of belt conveyor and belt machine, which is applied in the direction of conveyor, sending objects, transportation and packaging, etc. It can solve the problems of non-reusable, low work efficiency, complicated process, etc., and achieve the effect of promoting safe production and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

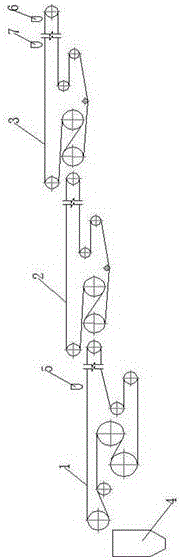

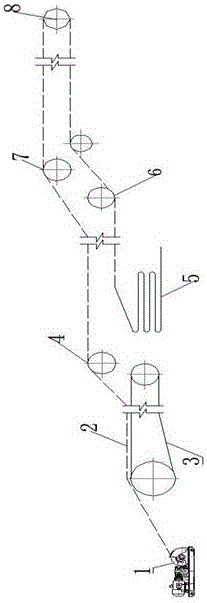

[0021] like figure 1 As shown, the main belt conveyor 1 of the north wing is driven by two 160KW three-phase asynchronous motors, with a designed transportation capacity of 400t / h and a total length of 1200 meters; the main belt conveyor 2 of the second north wing is a 250-type small belt conveyor. Type conveyor, driven by two 125kw three-stage asynchronous motors, with a total length of 460 meters; the main conveyor belt conveyor 3 of the third part of the north wing, with the same installed capacity and driving mode as the main conveyor belt conveyor of the second part of the north wing, with a total length of 1100 meters; No. 2 coal bunker 4, the lower port is connected to the coal feeder in the loading chamber, and then lifted to the ground through the skip of the main shaft. The entire north wing belt conveyor transportation system is sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com