Dirt cleaning and descaling device for fuel steam generator

A technology for decontamination, descaling and fuel steam, which is used in boiler cleaning devices, nuclear power generation, and greenhouse gas reduction. convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

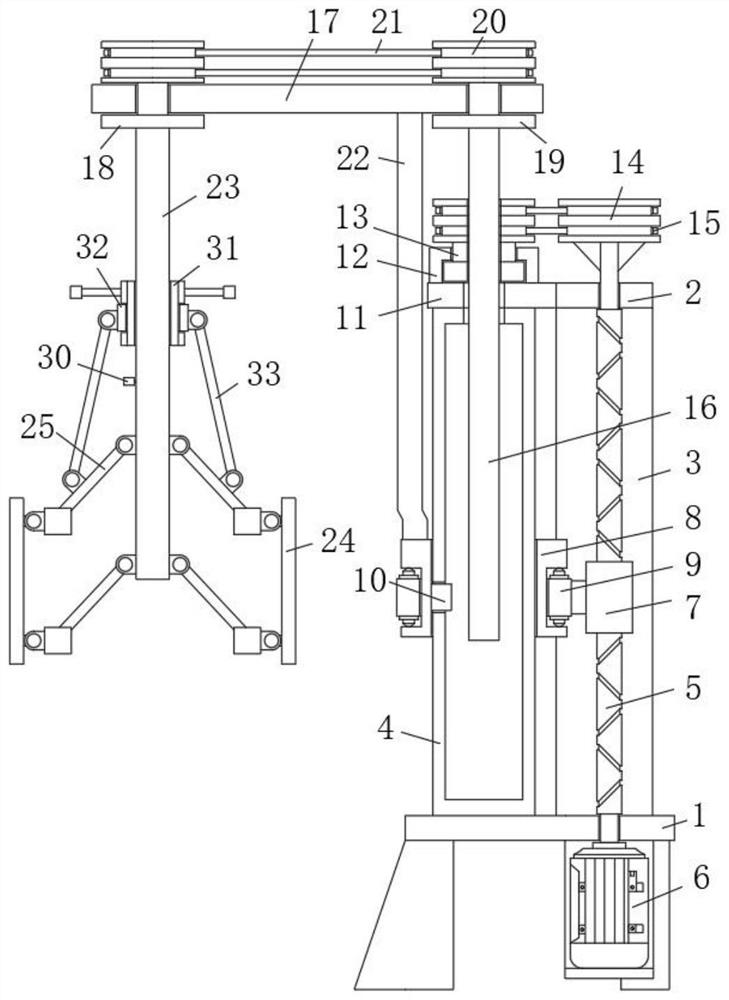

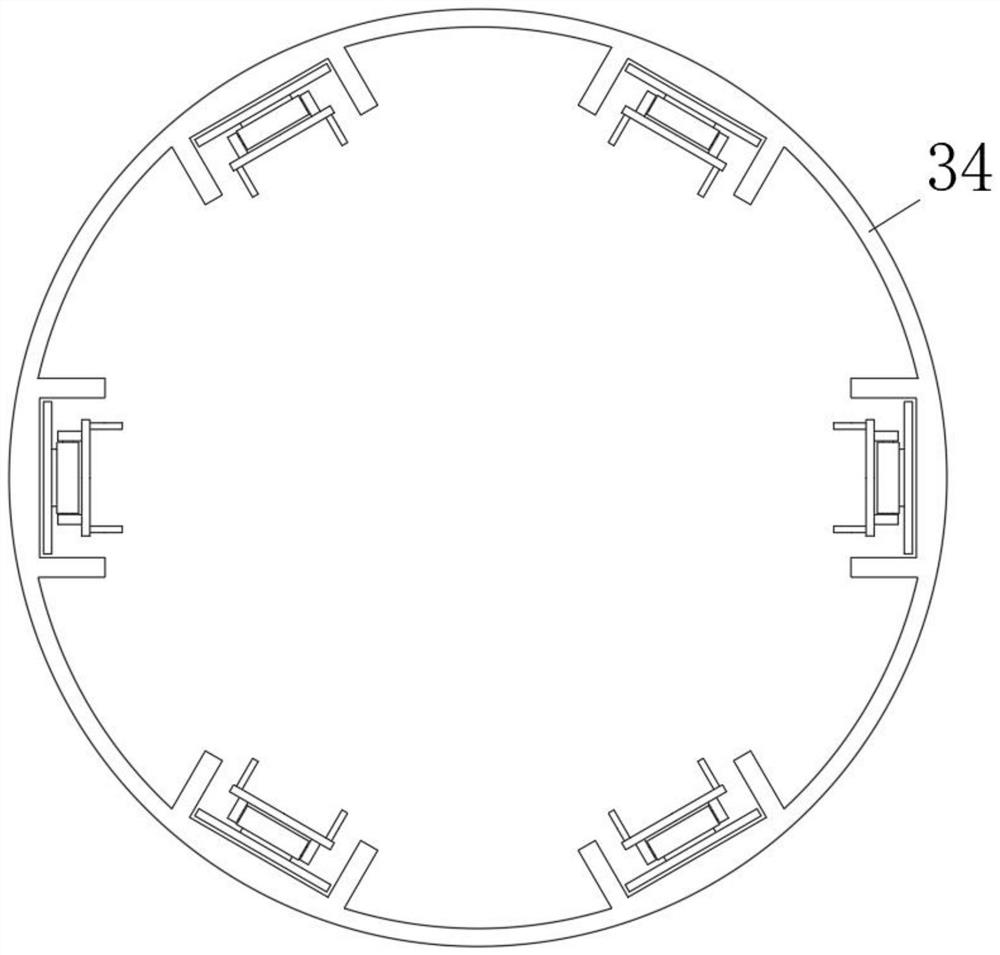

[0025] refer to Figure 1-4 , a decontamination and descaling device for a fuel steam generator, comprising a base 1, a top plate 2 and a dome table 11 fixed to each other are arranged vertically above the base 1, and between the bottom of the top plate 2 and the dome table 11 and the base 1 A column 3 and a rail vertical cylinder 4 are respectively fixed, a reciprocating screw 5 is rotatably installed between the top plate 2 and the base 1, a DC motor 6 is fixedly installed on one side of the base 1 by bolts, and the output shaft of the DC motor 6 is connected to the reciprocating screw. One end of 5 is drivingly connected, a rotating seat 12 is installed on the top side of the dome table 11, a rotating member 13 is rotatably installed in the rotating seat 12, and the rotating member 13 and the outer side of one end of the reciprocating screw , a transmission belt 15 is installed between the two pulleys 14, the rotating member 13 is provided with a polygonal vertical through ...

Embodiment 2

[0028] like Figure 1-4As shown, this embodiment is basically the same as Embodiment 1. Preferably, the outer side of the shaft body of the central shaft tube 23 is provided with a threaded groove and a threaded barrel 31 is threadedly sleeved. There is a collar 32, the bottom and the top of the scraper 24 are both hinged with a sizing umbrella shaft 25, and the other end of the sizing umbrella shaft 25 is hinged with the central axis tube 23, and the two central axis tubes 23 are arranged in parallel, A rotating connecting shaft 33 is rotatably installed between the middle part of the upper sizing umbrella shaft 25 and the vertical side of the collar 32 .

[0029] In this embodiment, when the inner wall is descaled for parts with different inner diameters, the threaded barrel 31 is manually screwed, the threaded barrel 31 moves in the vertical direction when the central axis tube 23 rotates, and the collar 32 moves relative to the threaded barrel 31 Rotating, the collar 32 m...

Embodiment 3

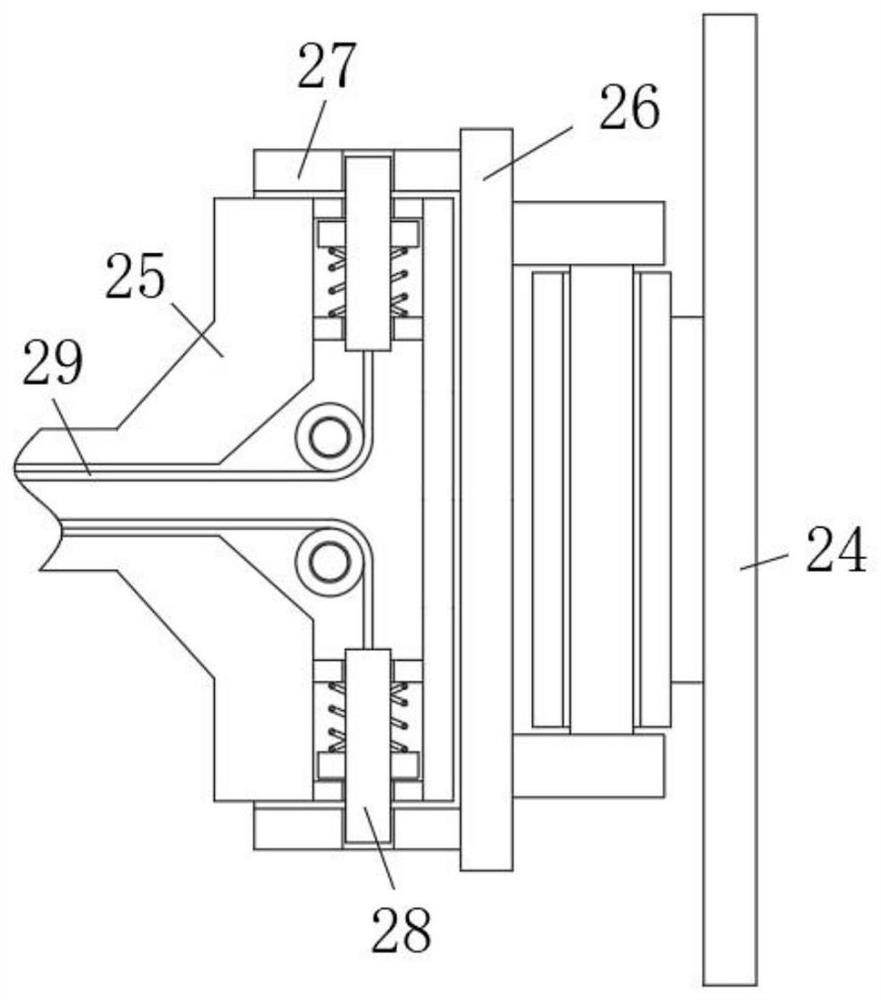

[0031] like Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, one end of the sizing umbrella shaft 25 is sleeved with a card seat 27, one end of the card seat 27 is fixedly connected with an installation vertical plate 26, and the scraper 24 is pivoted and hinged On the side where the riser 26 is installed.

[0032] In this embodiment, the installation of the scraper 24 is realized through the cooperation between the card seat 27 and the elastic bayonet 28 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com