Nano-fiber supported cobalt-silver alloy material as well as preparation method and application thereof

A technology of nanofibers and silver alloys, applied in fiber treatment, fiber chemical characteristics, chemical instruments and methods, etc., can solve problems such as cycle performance needs to be improved, graphene oxide conditions are complex and harsh, hydrogen release capacity is not high, etc., to achieve large Large-scale standardized production, high-efficiency catalyst loading, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

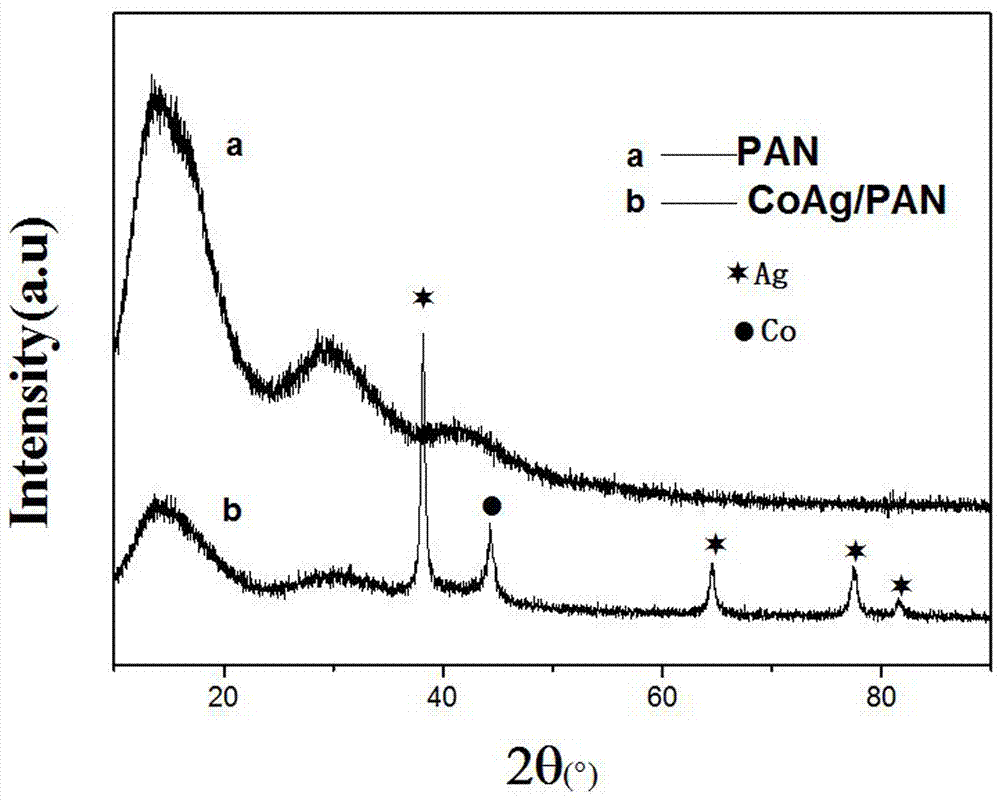

[0038] A preparation method of a nanofiber loaded cobalt-silver alloy material is as follows:

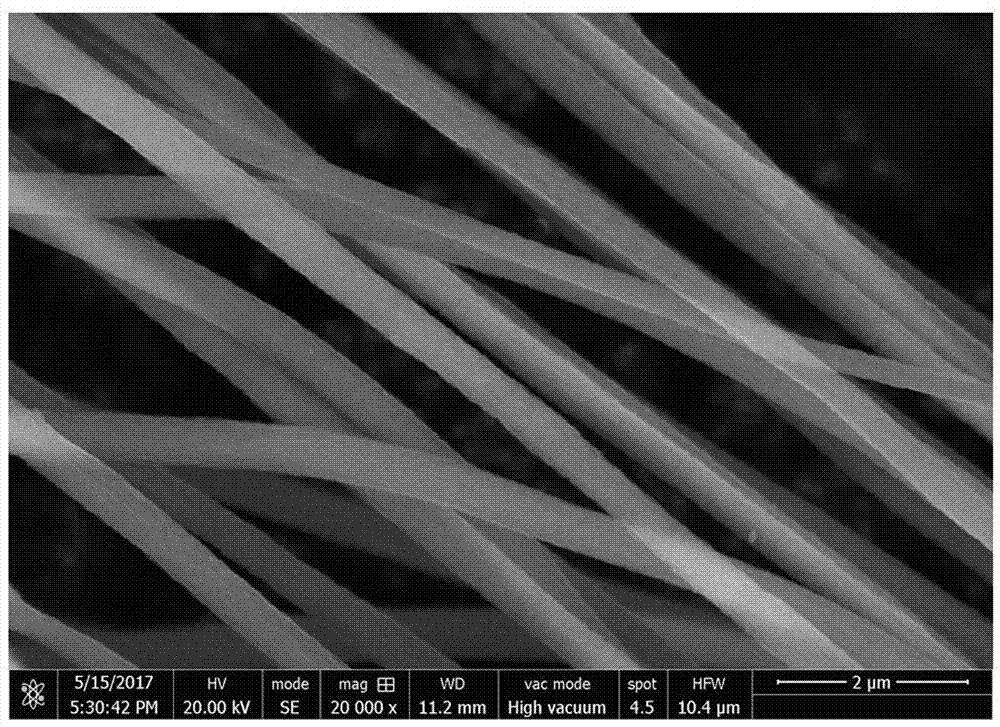

[0039] Step 1) Nanofibers were prepared by electrospinning, 1.5 g of polyacrylonitrile PAN was added to 8.5 g of dimethylformamide DMF, and the solution was continuously stirred in a water bath at 60 °C for 4 h until a uniform yellow precursor was obtained solution, and then put the precursor solution into a spinning tube with a needle opening of 1 mm, load the solution with a 10 ml syringe, set the spinning voltage to 10 kV, set the spinning distance to 12 cm, and set the advancing speed to 0.01 mm / min, spinning 10 h;

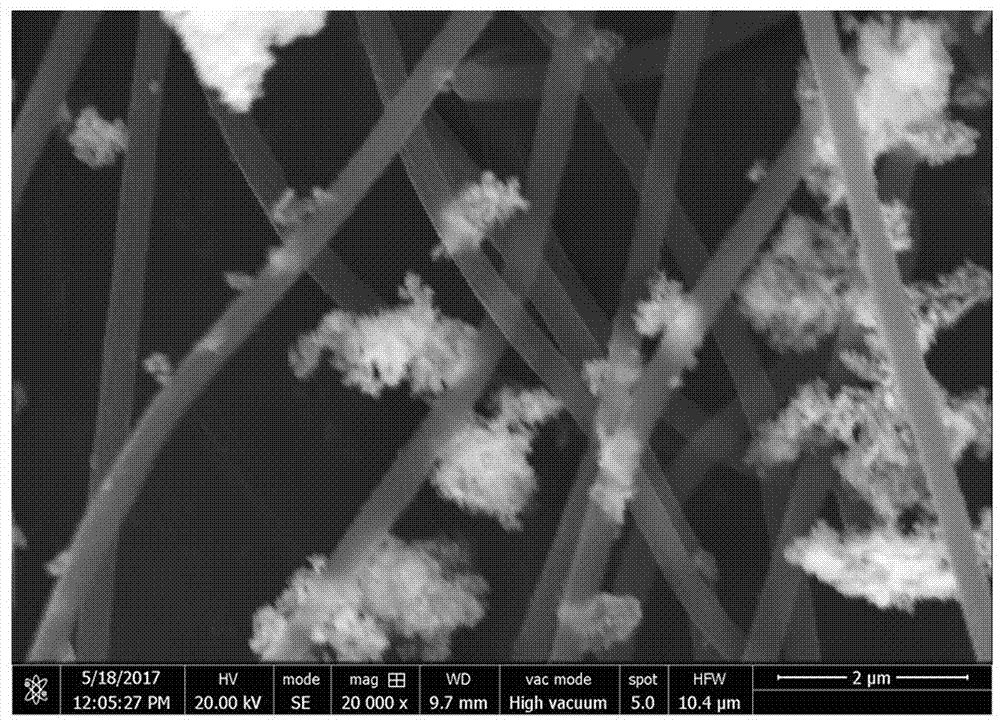

[0040] Step 2) Prepare cobalt particles by impregnation chemical reduction method, take 0.1 mol cobalt chloride, prepare 0.1 mol / L cobalt chloride solution, add dropwise 0.05 mol / L sodium borohydride solution under the condition of magnetic stirring, Stir while adding, after no bubbles are generated, filter under reduced pressure to obtain cobalt particles, wash w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com