A polyetheretherketone-based synergistic flame-retardant nanocomposite material and its preparation method

A nano-composite material, polyether ether ketone technology, applied in the field of polyether ether ketone-based synergistic flame-retardant nano-composite materials and its preparation, can solve the problems affecting the comprehensive performance of polyether ether ketone and a wider range of applications, poor performance etc. to achieve excellent thermal stability and thermal oxidation resistance, high mechanical properties, and high electrical insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

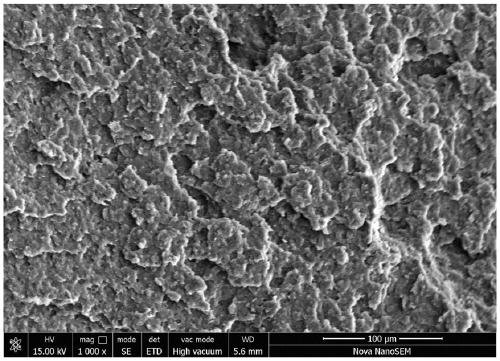

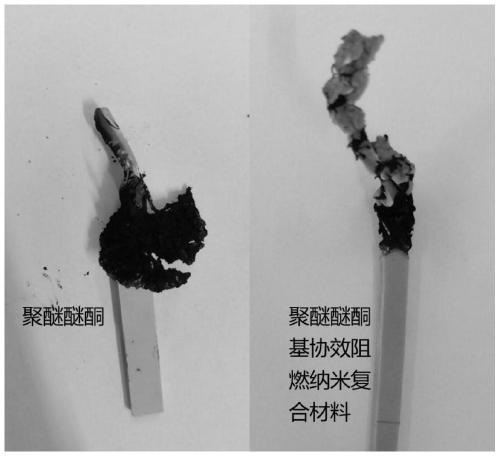

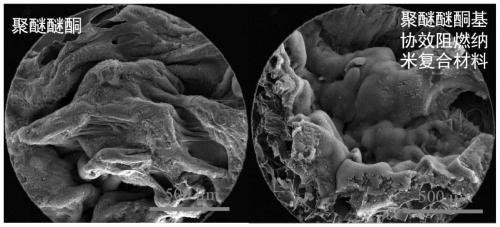

[0042] Add octaphenyl cage siloxane and polyether ether ketone superfine powder with a particle size of less than 25 μm (produced by Changchun Jida Special Plastic Engineering Research Co., Ltd.) into the anhydrous ethanol dispersion, ultrasonically disperse for 24 hours, and then spin dry , the prepared mixed powder; the prepared mixed powder and the surface-modified nano-calcium carbonate with a particle size of 40-80nm are mixed into the polyether ether ketone powder with a particle size of 50-100 μm, and stirred at high speed for 20 minutes to obtain a synergistic flame-retardant Polyether ether ketone powder; the powder is extruded by twin-screw, and the heating temperatures in the five zones are respectively, the temperature in the first zone is 260°C, the temperature in the second zone is 350°C, the temperature in the third zone is 380°C, the temperature in the fourth zone is 385°C, and the temperature in the fifth zone is 380°C. The zone temperature is 390°C, the screw ...

Embodiment 2

[0049] Add octaphenyl cage siloxane and polyether ether ketone superfine powder with a particle size of less than 25 μm (produced by Changchun Jida Special Plastic Engineering Research Co., Ltd.) into the anhydrous ethanol dispersion, ultrasonically disperse for 24 hours, and then spin dry , the prepared mixed powder; the prepared mixed powder and the surface-modified nano-calcium carbonate with a particle size of 40-80nm are mixed into the polyether ether ketone powder with a particle size of 50-100 μm, and stirred at high speed for 20 minutes to obtain a synergistic flame-retardant Polyether ether ketone powder; the powder is extruded by twin-screw, and the heating temperatures in the five zones are respectively, the temperature in the first zone is 260°C, the temperature in the second zone is 350°C, the temperature in the third zone is 380°C, the temperature in the fourth zone is 385°C, and the temperature in the fifth zone is 380°C. The zone temperature is 390°C, the screw ...

Embodiment 3

[0056] Add octaphenyl cage siloxane and polyether ether ketone superfine powder with a particle size of less than 25 μm (produced by Changchun Jida Special Plastic Engineering Research Co., Ltd.) into the anhydrous ethanol dispersion, ultrasonically disperse for 24 hours, and then spin dry , the prepared mixed powder; the prepared mixed powder and the surface-modified nano-calcium carbonate with a particle size of 40-80nm are mixed into the polyether ether ketone powder with a particle size of 50-100 μm, and stirred at high speed for 20 minutes to obtain a synergistic flame-retardant Polyether ether ketone powder; the powder is extruded by twin-screw, and the heating temperatures in the five zones are respectively, the temperature in the first zone is 260°C, the temperature in the second zone is 350°C, the temperature in the third zone is 380°C, the temperature in the fourth zone is 385°C, and the temperature in the fifth zone is 380°C. The zone temperature is 390°C, the screw ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com