Preparation method of gadolinium tungstate fluorescent powder

A fluorescent powder, gd2-xw2o9 technology, applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of inability to meet market demand, low luminous intensity of products, harsh synthesis conditions, etc., and achieve easy market promotion and application, uniform size , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

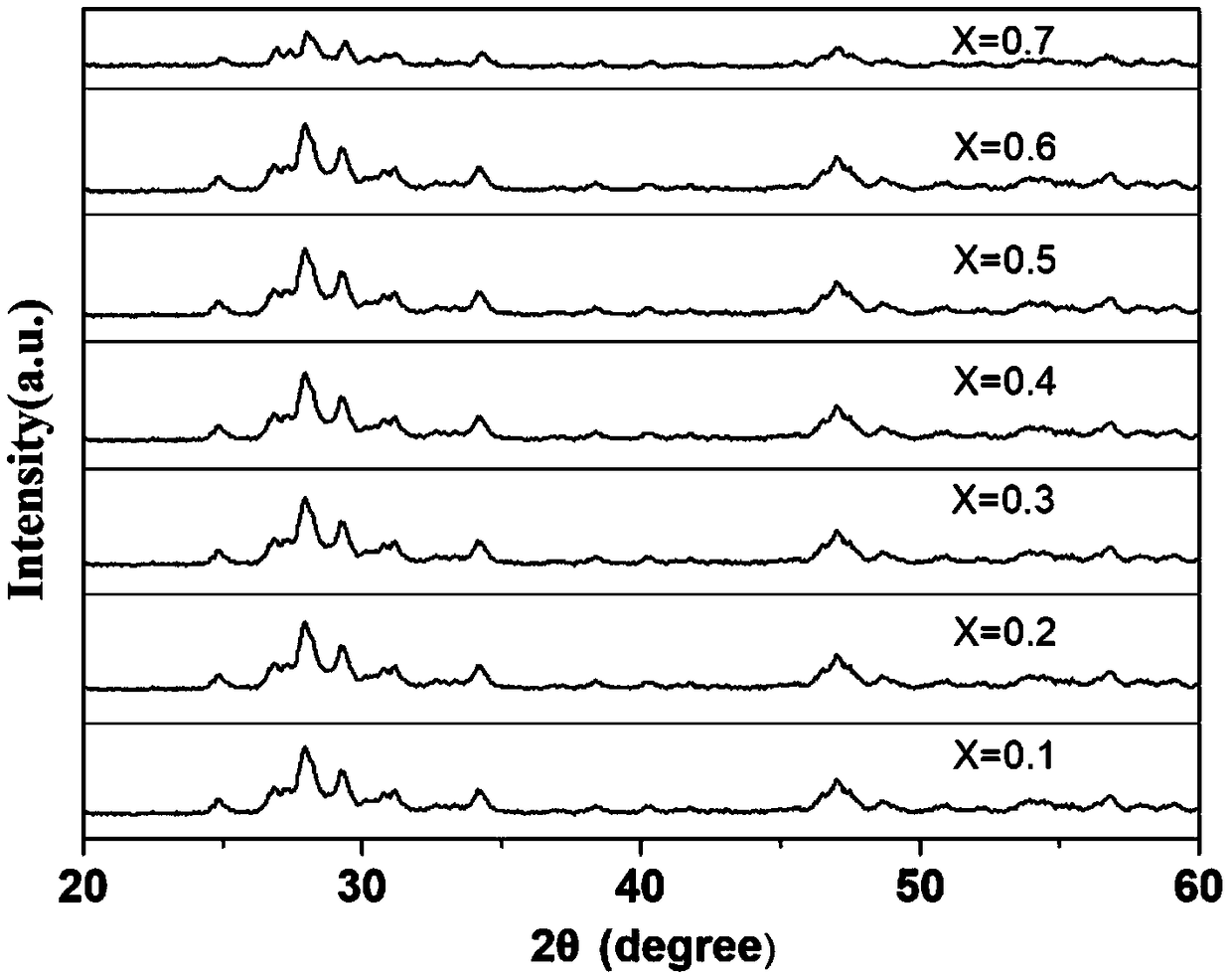

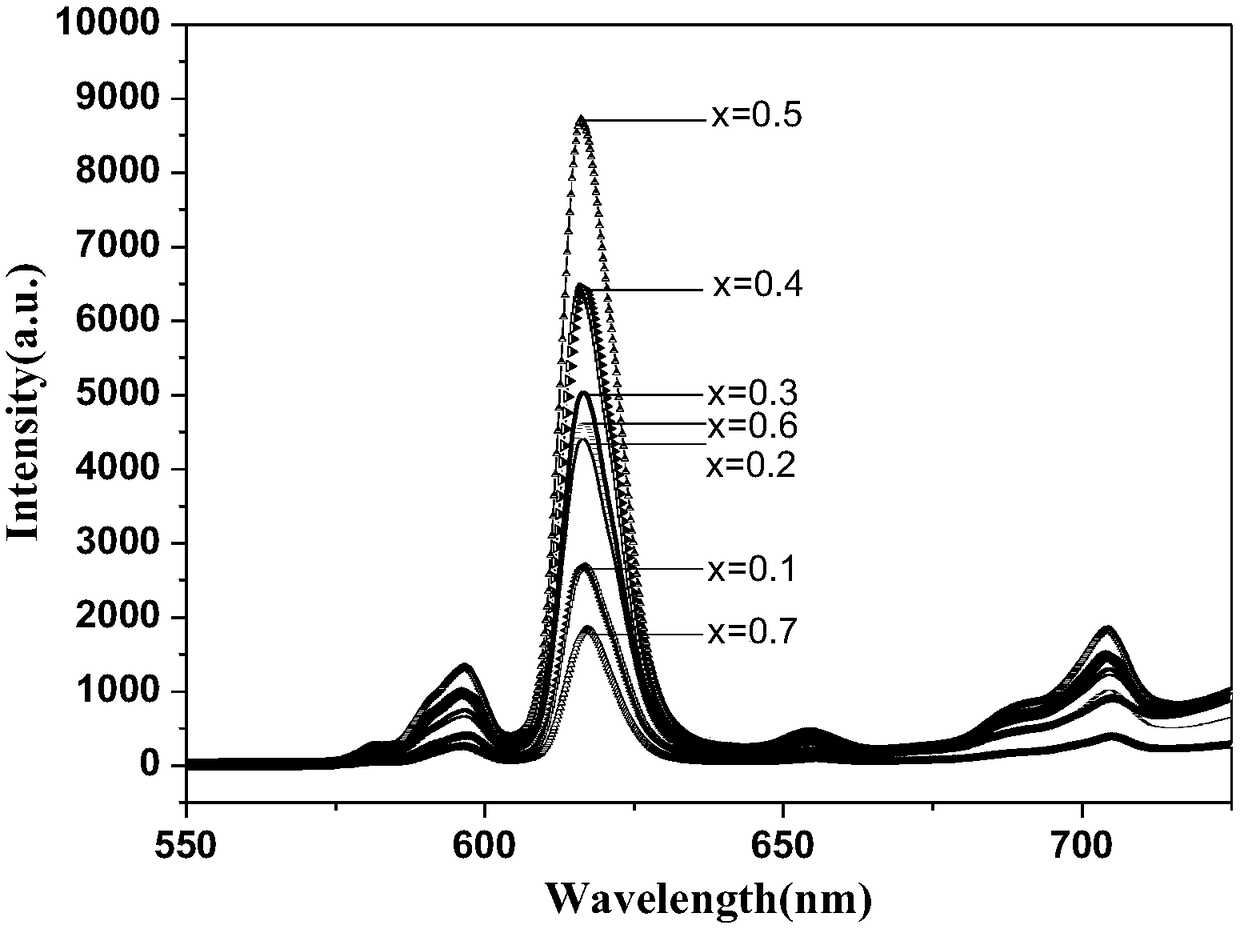

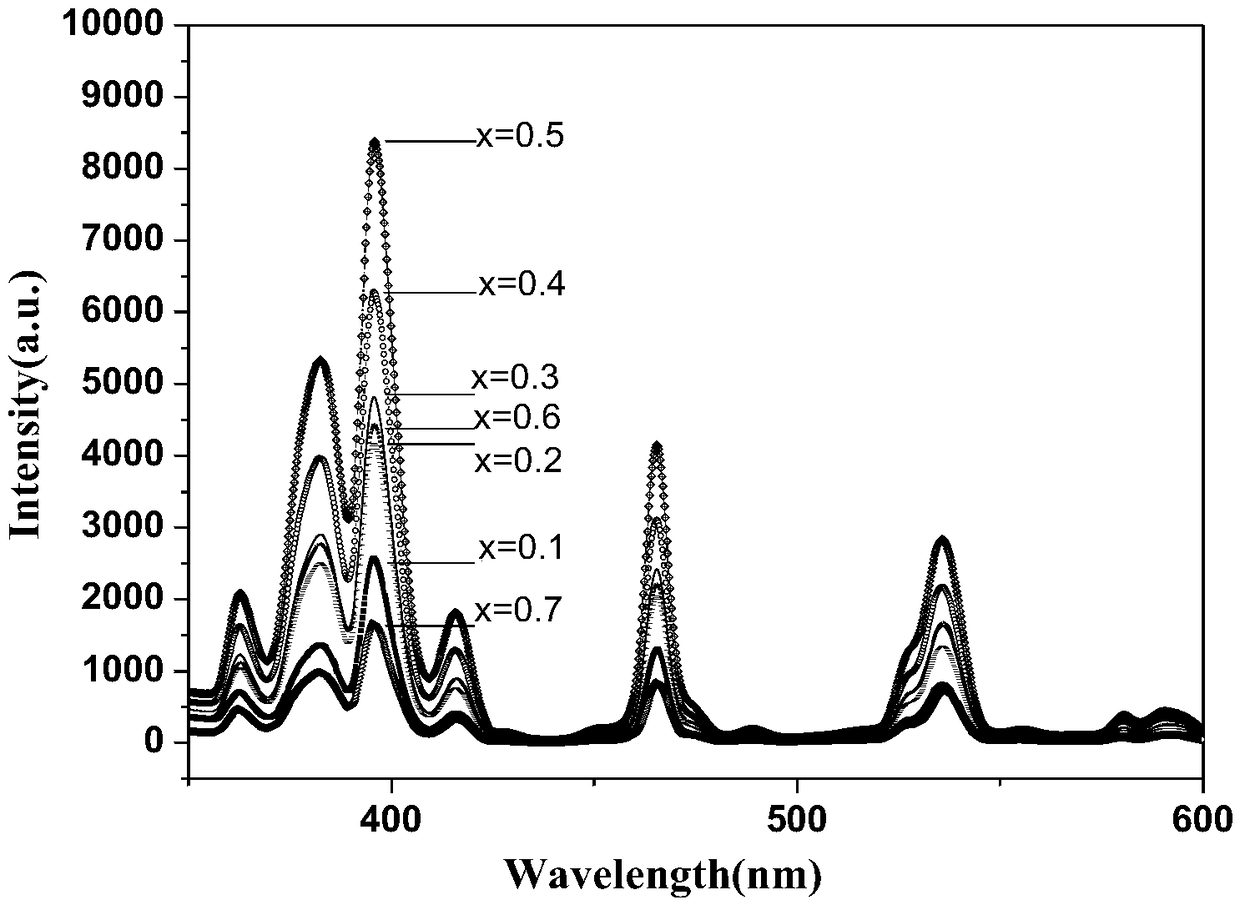

[0018] Example 1 Gd 1.5 W 2 o 9 :0.5Eu 3+ Preparation of:

[0019] Weigh Gd separately 2 o 3 0.6788g, WO 3 1.1602g, Eu 2 o 3 0.2201g, then take by weighing the surfactant of 1.4wt% of the above raw material gross mass (hexadecyltrimethylammonium bromide: sodium dodecylbenzenesulfonate: the mass ratio of Polyethylene Glycol 200 is 1: 2:0.8); Gd to be weighed 2 o 3 , WO 3 , Eu 2 o 3 , mixed with surfactants, according to the ball-to-material ratio of 7:1, put in agate balls, add alcohol, the amount of lubricant added is limited to be kept dispersed by the ball mill system, and the ball mill is mixed for 4 hours to obtain a mixed powder.

[0020] (3) Put the mixed powder into a corundum crucible, place it in a high-temperature furnace for calcination, raise the temperature to 200°C at a heating rate of 10°C per minute, keep it warm for 19 minutes, and then raise the temperature to 800°C at a heating rate of 10°C per minute Calcination at heat preservation for 1.5...

Embodiment 2

[0022] Example 2 Gd 1.9 W 2 o 9 :0.1Eu 3+ Preparation of:

[0023] Weigh Gd separately 2 o 3 0.8596, WO 3 1.1600g, Eu 2 o 3 0.0441g, then take by weighing the surfactant of 1.3wt% of the above raw material gross mass (hexadecyltrimethylammonium bromide: sodium dodecylbenzenesulfonate: the mass ratio of Polyethylene Glycol 200 is 1: 3:0.7); Gd to be weighed 2 o 3, WO 3, Eu 2 o 3, Surfactants are mixed, according to the ball-to-material ratio of 8:1, agate balls are added, acetone is added, the amount of lubricant added is limited to be kept dispersed by the ball mill system, and the ball mill is mixed for 5 hours to obtain a mixed powder.

[0024](3) Put the mixed powder into a corundum crucible, place it in a high-temperature furnace for calcination, raise the temperature to 210°C at a heating rate of 12°C per minute, and heat it for 18 minutes, then raise the temperature to 850°C at a heating rate of 12°C per minute Calcination at heat preservation for 1h, af...

Embodiment 3

[0026] Example 3 Gd 1.8 W 2 o 9 :0.2Eu 3+ Preparation of:

[0027] Weigh Gd separately 2 o 3 0.8147, WO 3 1.1603g, Eu 2 o 3 0.0881g, then take by weighing the surfactant of 1.5wt% of the above raw material gross mass (hexadecyltrimethylammonium bromide: sodium dodecylbenzenesulfonate: the mass ratio of Polyethylene Glycol 200 is 1: 1:0.9); Gd to be weighed 2 o 3, WO 3, Eu 2 o 3, Surfactants are mixed, according to the ball-to-material ratio of 3:1, put in agate balls, add alcohol, the amount of lubricant added is limited to be kept dispersed by the ball mill system, and the ball mill is mixed for 2 hours to obtain a mixed powder.

[0028] (3) Put the mixed powder into a corundum crucible, place it in a high-temperature furnace for calcination, raise the temperature to 190°C at a heating rate of 8°C per minute, keep it warm for 22 minutes, and then raise the temperature to 700°C at a heating rate of 8°C per minute Calcination at heat preservation for 2h, after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com