Deviated well in-situ combustion continuous-tube electric ignition tubular column and ignition method

A technology of burning oil layers and electric ignition, which is applied in earthwork drilling, wellbore/well components, production fluids, etc. It can solve the problems of heating air heat loss, reducing fire drive efficiency, and air injection into oil layers, etc., so as to reduce investment costs, The effect of improving the ignition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

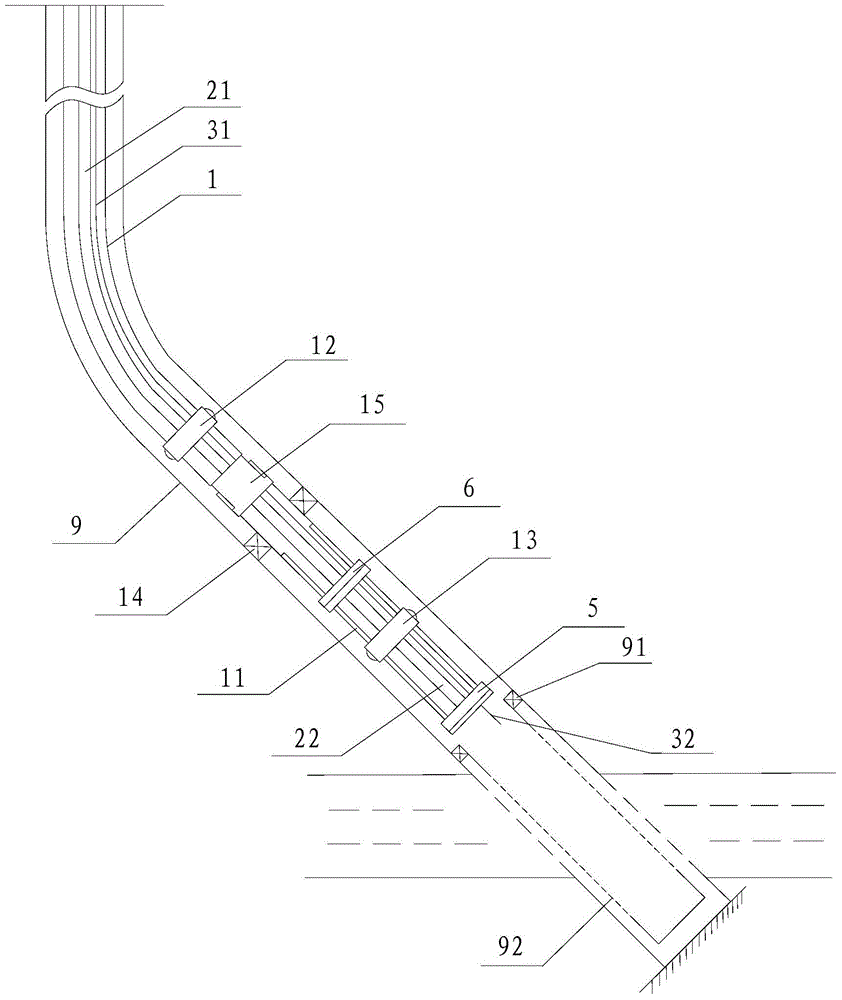

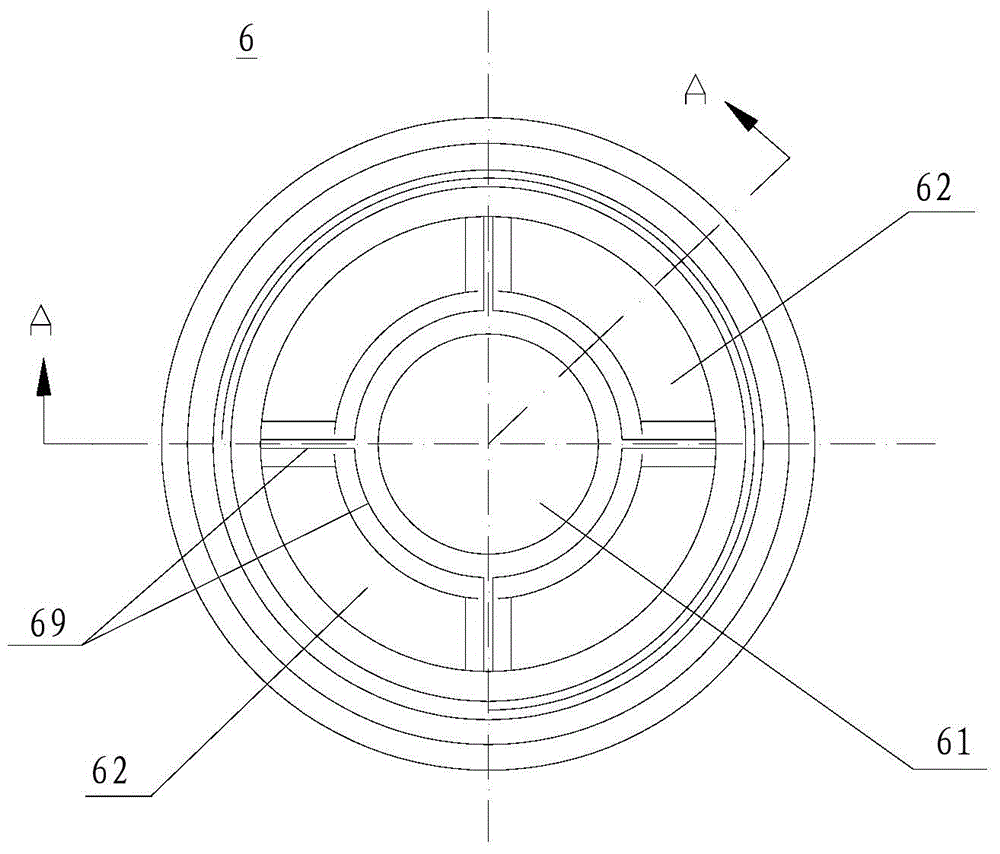

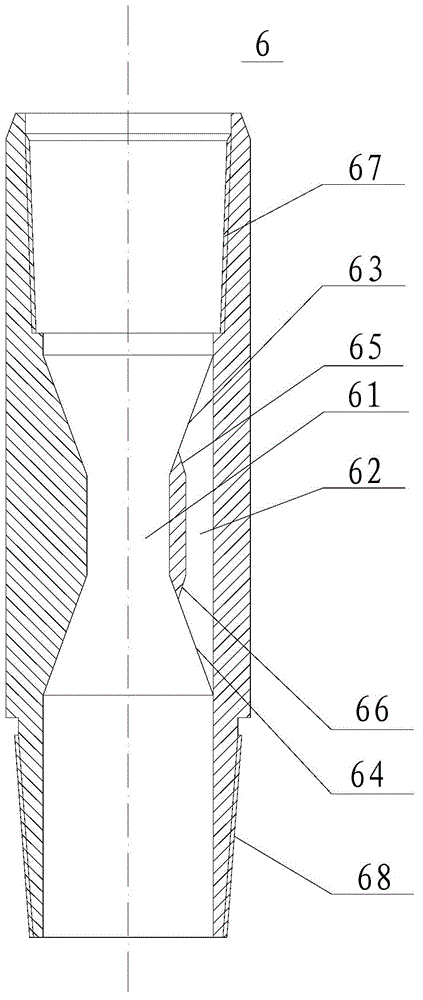

[0042] see figure 1 As shown, the present invention provides a coiled tubing electric ignition string for incubating oil layers in inclined wells. The string is provided with an electric ignition cable 21 and a monitoring cable 31 in the oil pipe 1, and at least one guide and centralizer is provided between the oil pipe 1 sections. 6, and a guide limiter 5 is provided at the bottom end of the oil pipe 1; the electric ignition cable 21 passes through the guide centralizer 6 and is suspended in the oil pipe 1, and the bottom end of the electric ignition cable 21 is connected to the electric ignition 22, the electric igniter 22 is supported in the guide limiter 5; the monitoring cable 31 is suspended in the oil pipe 1 through the guide centralizer 6 and the guide limiter 5 respectively, and monitors The bottom end of the cable 31 protrudes from the oil pipe 1 and is connected with a sensor 32, which may be a temperature and pressure probe of a gas injection well.

[0043] Such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com