Treatment method for resource utilization of waste liquid in production of graphene oxide

A processing method, graphene technology, applied in chemical instruments and methods, filtration treatment, multi-stage water treatment, etc., to achieve the effects of simple operation, reduced operating costs, and improved economic benefits of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

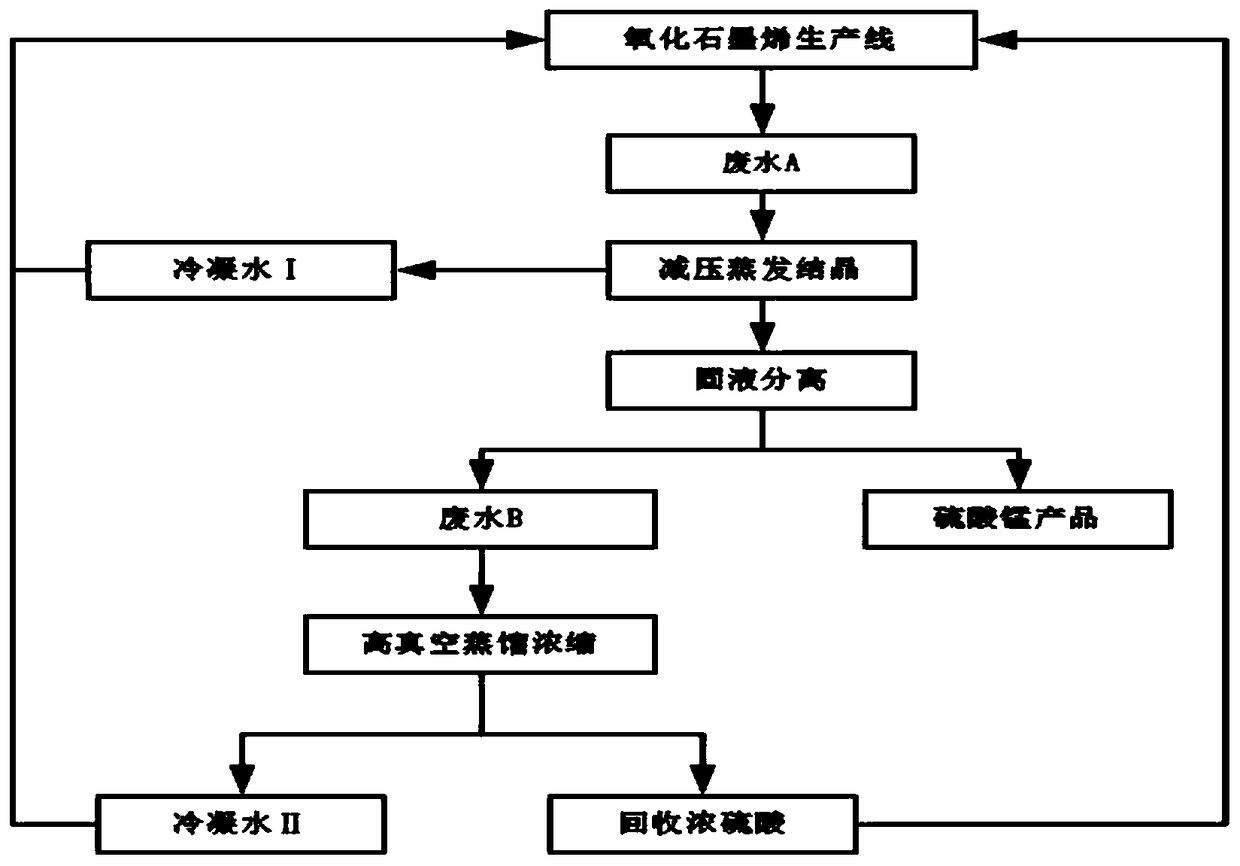

[0040] The schematic diagram of the process is as follows figure 1 As shown, the specific operation is as follows:

[0041] (1) Wastewater pretreatment: use the acid-resistant pump to inject the waste water produced in the production into the stock solution tank for pretreatment, filter and remove solid impurities, and obtain clarified waste water A (containing SO 4 2- 、H 3 o + , Mn 2+ ).

[0042] (2) Evaporation and crystallization: The above-mentioned clarified waste water A is introduced into the evaporation and crystallization system, and the temperature is controlled at 85° C., the pressure is -0.085 MPa, and the stirring speed is 170 r / min, and the vacuum evaporation concentration is carried out. The whole process adopts negative pressure technology to reduce the evaporation temperature.

[0043] After the sulfuric acid waste liquid is evaporated and concentrated to a certain extent, manganese sulfate crystals appear. When manganese sulfate is close to saturation,...

Embodiment 2

[0050] The schematic diagram of the process is as follows figure 1 As shown, the specific operation is as follows:

[0051] (1) Wastewater pretreatment: use the acid-resistant pump to inject the waste water produced in the production into the stock solution tank for pretreatment, filter and remove solid impurities, and obtain clarified waste water A (containing SO 4 2- 、H 3 o + , Mn 2+ ).

[0052] (2) Evaporation and crystallization: The above-mentioned clarified waste water A is introduced into the evaporation and crystallization system, and the temperature is controlled at 90°C, the pressure is -0.080MPa, and the stirring speed is 160r / min, and the vacuum evaporation and concentration are carried out. The whole process adopts negative pressure technology to reduce the evaporation temperature.

[0053] After the sulfuric acid waste liquid is evaporated and concentrated to a certain extent, manganese sulfate crystals appear. When manganese sulfate is close to saturation...

Embodiment 3

[0059] The schematic diagram of the process is as follows figure 1 As shown, the specific operation is as follows:

[0060] (1) Wastewater pretreatment: use the acid-resistant pump to inject the waste water produced in the production into the stock solution tank for pretreatment, filter and remove solid impurities, and obtain clarified waste water A (containing SO 4 2- 、H 3 o + , Mn 2+ ).

[0061] (2) Evaporation and crystallization: the above-mentioned clarified waste water A is introduced into the evaporation and crystallization system, and the temperature is controlled at 70°C, the pressure is -0.090MPa, and the stirring speed is 200r / min, and the vacuum evaporation concentration is carried out. The whole process adopts negative pressure technology to reduce the evaporation temperature.

[0062] After the sulfuric acid waste liquid is evaporated and concentrated to a certain extent, manganese sulfate crystals appear. When manganese sulfate is close to saturation, man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com