Waste water treatment method in preparation of para-amiophenyl by electrolytic process

A technology of p-aminophenol and a treatment method, applied in the field of wastewater treatment, can solve the problems of environmental pollution, insufficient rationality and economy of treatment process, loss of PAP and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

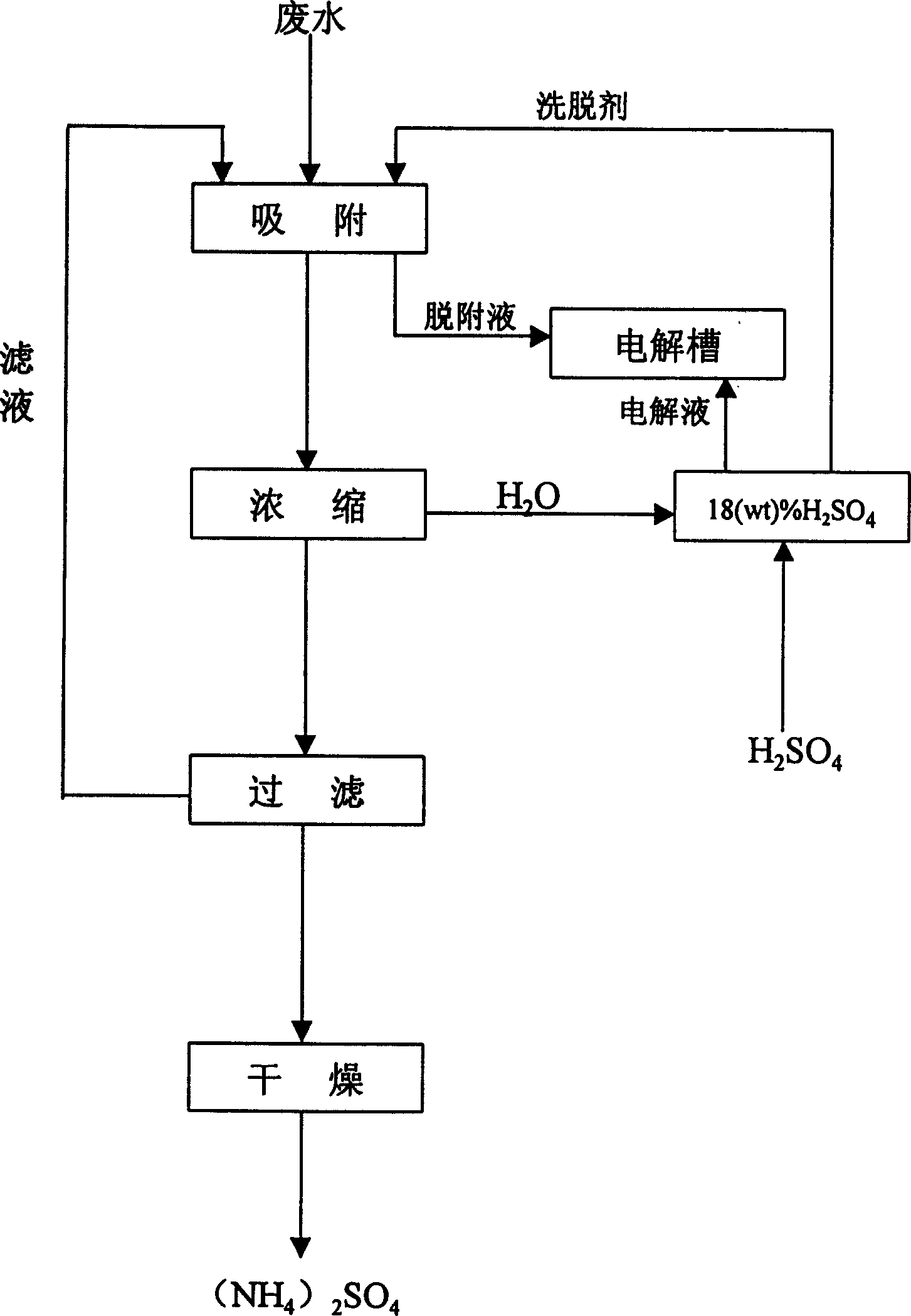

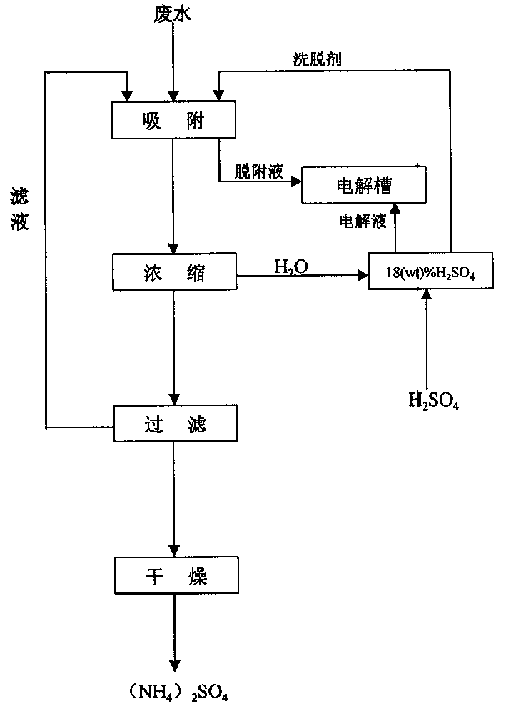

Method used

Image

Examples

Embodiment 1

[0016] 1. Take 65L of waste water, light yellow, pH = 7.0, specific gravity 1.12. This batch of waste water is made of 6.25 kg of nitrobenzene, 6.8 kg of sulfuric acid and an appropriate amount of water to participate in the electrolysis reaction, after treatment, purification and separation of PAP.

[0017] 2. After adsorbing PAP through the adsorption column of fruit shell activated carbon [1kg, divided into 3 levels, each level is 1m (the working section is 0.7m), the particle size of the fruit shell activated carbon is 8-20 mesh (the linear velocity of wastewater in the adsorption column is 0.15- 0.3m / s, the adsorption temperature is 55~60℃), the solution is colorless and transparent, the specific gravity is 1.12, pH=7.0, based on the adsorption raw material liquid PAP inlet concentration of 1.3g / L, the actual adsorption liquid PAP outlet concentration is less than 10 -4 g / L, the PAP adsorption rate is greater than 99%.

[0018] 3. Send the above-mentioned liquid obtained ...

Embodiment 2

[0025] Repeat the first item of Example 1, 1 kg of fruit shell activated carbon is equally divided into 5 parts, and cross-flow adsorption is performed in a stirred tank. After 5 stages of cross-flow adsorption, the PAP concentration is 0.24g / l. In this case, the adsorption solution is as described in Example 1. Middle 3-5 step method processes, reclaims gained (NH 4 ) 2 SO 4 The quality does not meet the requirements of industrial purity, its organic content> 0.1%, (NH 4 ) 2 SO 4 The color of the skin is white at first, and becomes slightly brownish red after 1 day, and becomes darker and darker after a few days.

Embodiment 3

[0027] Repeat the 1st to the 5th item of embodiment one, but the 6th step gac regeneration, adopt 18%H 2 SO 4 The aqueous solution flows through the activated carbon adsorption column continuously and slowly for desorption, adopts the leaching method for desorption and the leaching time is less than 5 hours, and other conditions are not within the scope of the operating conditions of step 6 in Example 1. Facts have proved that the regeneration rate of activated carbon at this time is <70%, and it cannot be recycled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com