Heating furnace cooling energy medium self-recovery system

An energy medium and self-recovery technology, which is applied in the direction of furnace cooling, energy efficiency improvement, lighting and heating equipment, etc., can solve problems affecting the normal production of heating furnaces, destroying vaporization cooling system pipes and equipment, temperature and pressure rise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

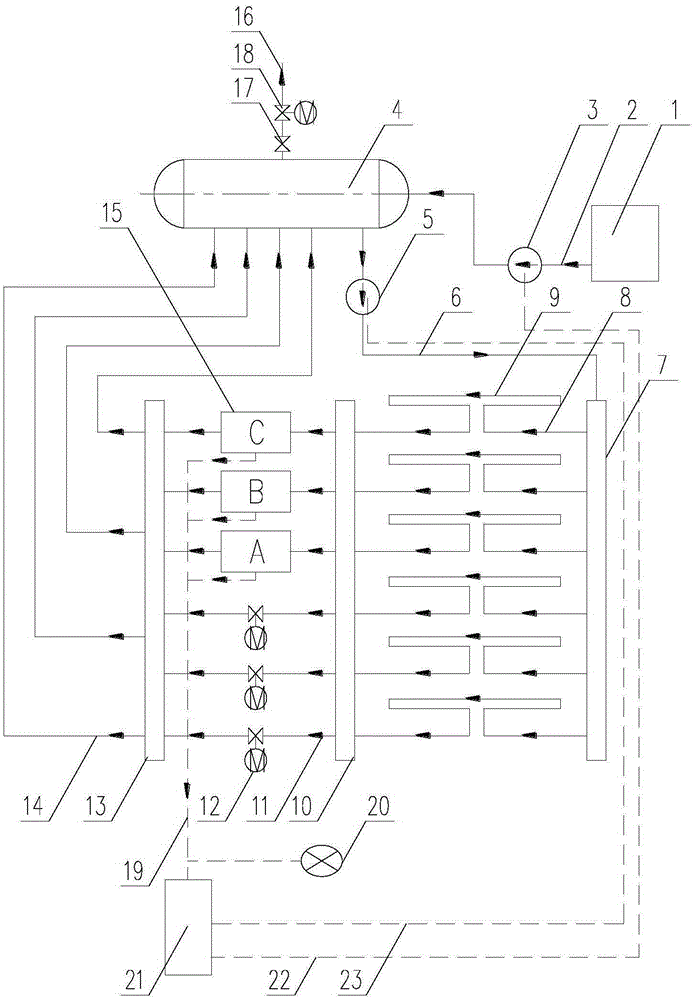

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] Such as figure 1 As shown, the heating furnace cooling energy medium self-recovery system of the present invention includes a steam drum 4, and the inlet distribution header 7, the water beam 9 in the furnace, the first outlet distribution header 10, and the generator set 15 are sequentially connected to the steam drum 4 And the second outlet distribution header 13.

[0025] Wherein the water outlet of the steam drum 4 is connected to the inlet distribution device 7 through the downcomer 6, and the downcomer 6 is provided with a circulation pump 5; The water beam 9 is connected; the water beam 9 in the furnace is connected with the first outlet distribution header 10 through the circulation pipeline 8; the first outlet distribution header 10 is distributed with the second outlet through a pipeline group 11 The headers 13 are connected, and the pipeline group 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com