Activated carbon continuous sorption-desorption device for movable bed

A technology of activated carbon and adsorption and desorption, which is applied to the separation of dispersed particles, chemical instruments and methods, and separation methods. Adsorption and desorption efficiency, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

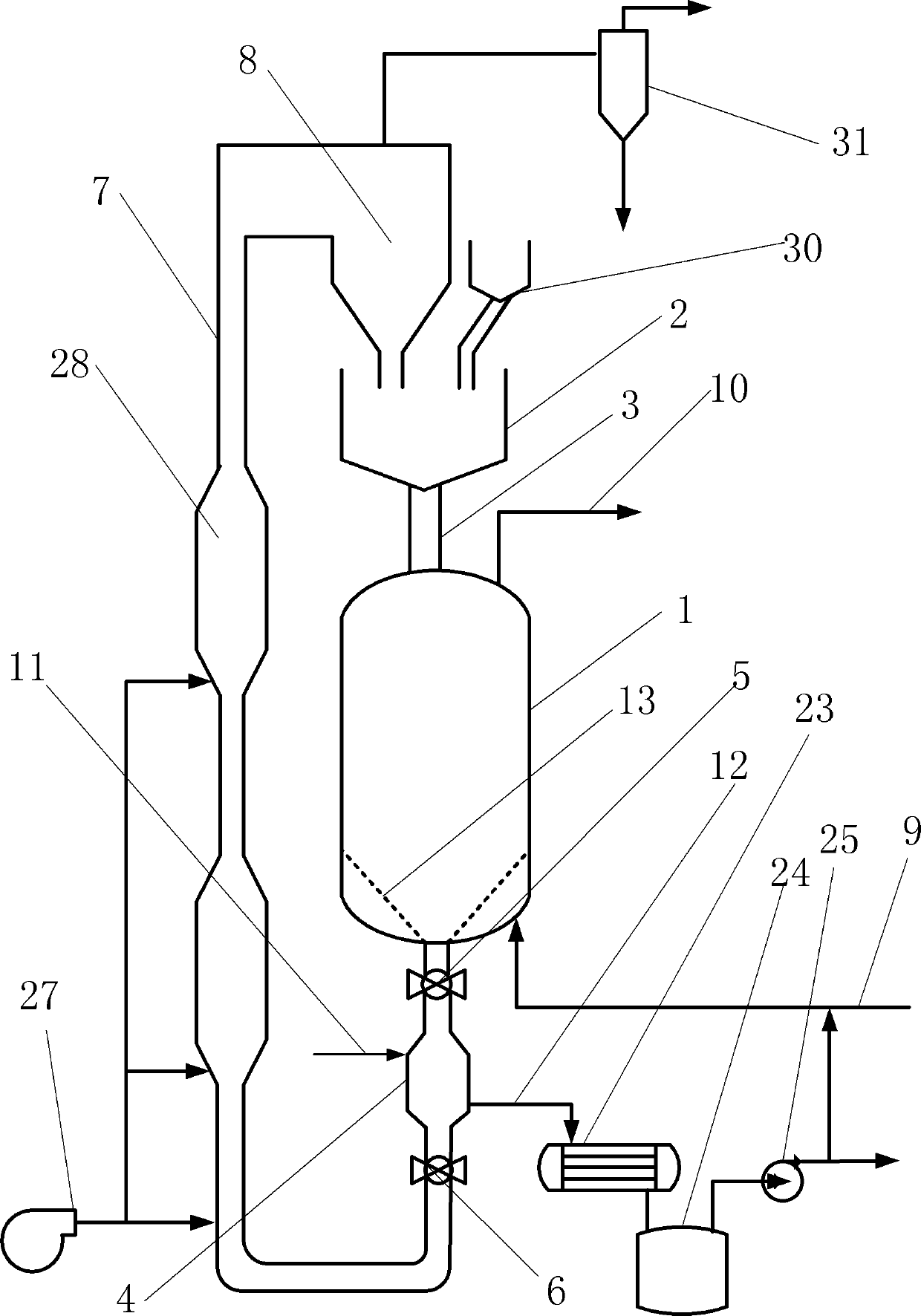

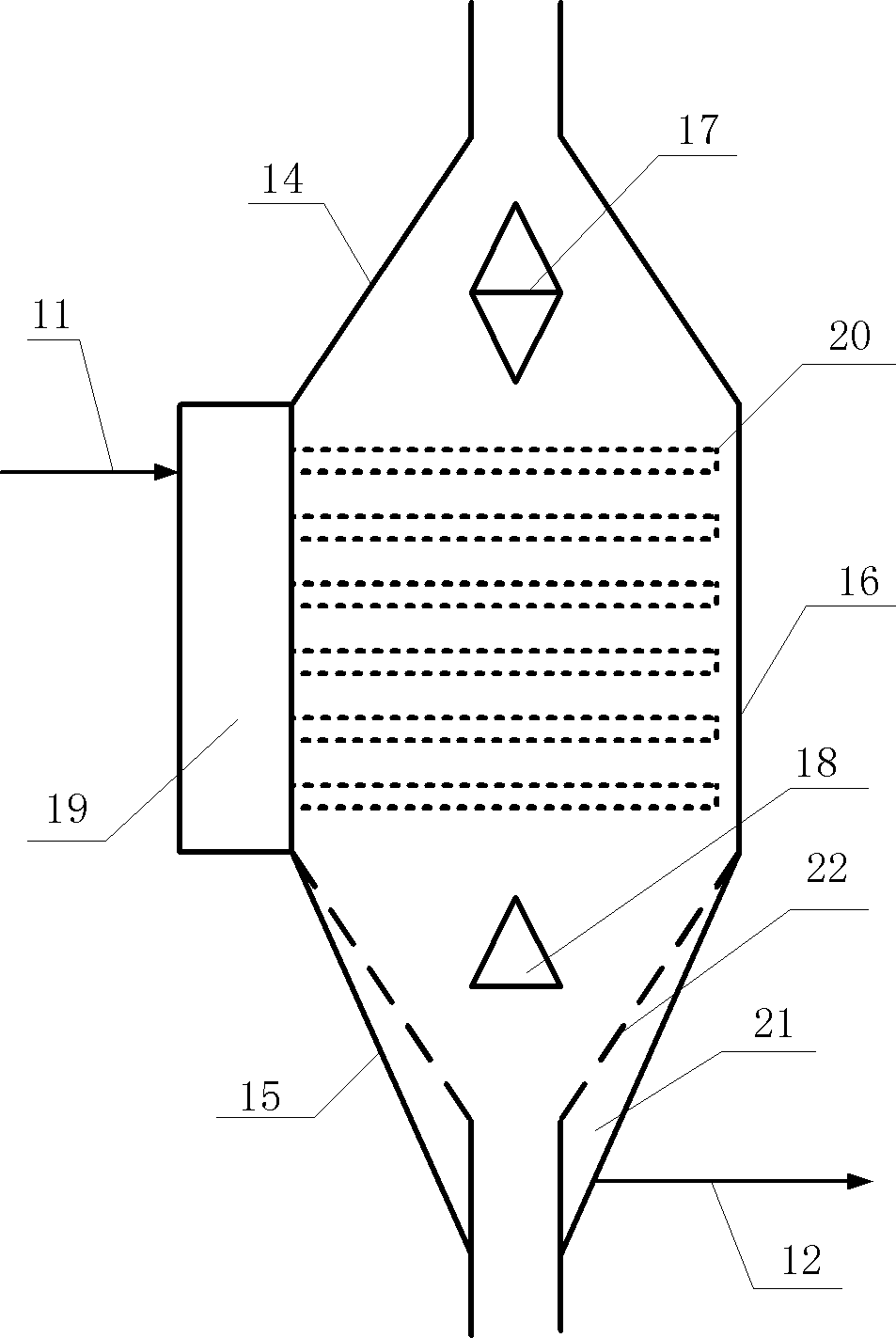

Embodiment 1

[0030] Adopt device of the present invention to contain toluene 3000mg / m 3 The air is processed, and the air volume of the drying fan 27 is 8000m 3 / h, normal temperature, the diameter of adsorber 1 is 1.75m, and height is 2m, carries out adsorption-desorption operation with the coconut shell activated carbon particle of commercially available diameter 6mm, and its specific flow process is carried out according to above-mentioned flow process, and its result is to reclaim toluene per hour 22.7 kg, the adsorption recovery efficiency is 94.6%, which improves the adsorption and desorption efficiency, and uses 70 kg of desorption steam at 105°C, which reduces the adsorption and desorption cost.

Embodiment 2

[0032] Adopt the device of the present invention to contain benzene 8000mg / m 3 The air is processed, and the air volume of the drying fan 27 is 5000m 3 / h, normal temperature, the diameter of the adsorber 1 is 1.75m, and the height is 2m. The commercially available coconut shell activated carbon particles with a diameter of 6mm are used for adsorption and desorption operations. kg, the adsorption recovery efficiency is 95.3%, which improves the adsorption and desorption efficiency, and uses 120kg of desorption steam at 105°C, which reduces the adsorption and desorption cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com