A method and device for degrading organic wastewater using micro-active oxygen generated by electrocatalytic reduction of air oxygen

A technology of organic wastewater and micro-activity, which is applied in chemical instruments and methods, gaseous effluent wastewater treatment, special compound water treatment, etc. High, improve the contact area, improve the effect of catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

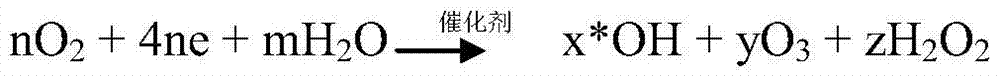

Method used

Image

Examples

Embodiment 1

[0041] The oxygen reduction catalyst in this embodiment is composed of a main catalyst and an auxiliary catalyst. The main catalyst is platinum, and the main catalyst is loaded onto activated carbon through a chemical reaction. onto activated carbon particles, and then dried to form activated carbon coated with platinum black, the weight ratio of platinum black to activated carbon in the activated carbon coated with platinum black is 1:10; the auxiliary catalyst is nitrogen-containing microporous carbon, and the nitrogen-containing microporous The weight ratio of nitrogen and carbon in the porous carbon is 0.5:100, and the weight ratio of the main catalyst and the auxiliary catalyst is 1:5.

[0042] Design an electrochemical reactor device, the device is equipped with an anode and a cathode, the anode is a graphite rod, the anode is connected to the positive electrode of the power supply by a wire; the cathode is a titanium basket, and the cathode titanium basket is filled with...

Embodiment 2

[0046] The oxygen reduction catalyst of the present embodiment is made up of main catalyst and auxiliary catalyst, and main catalyst is Pd-Fe, and auxiliary catalyst is nitrogen-containing microporous carbon, and main catalyst Pd-Fe is the Fe particle of chemical plating Pd, and in described main catalyst, Pd The weight ratio to Fe is 1:100; the auxiliary catalyst is nitrogen-containing microporous carbon, and the weight ratio of nitrogen to carbon in the nitrogen-containing microporous carbon is 0.5:100, and the weight ratio of the main catalyst and the auxiliary catalyst is It is 1:10.

[0047] Design an electrochemical reactor device, the device is equipped with an anode and a cathode, the anode is a graphite rod, the anode is connected to the positive electrode of the power supply by a wire; the cathode is a titanium basket, and the cathode titanium basket is filled with activated carbon and oxygen reduction catalyst. The specific filling method The method is: first mix th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com