A flue gas reheating dish-type solar thermal and gas-steam combined cycle power generation system

A technology of combined cycle power generation and gas steam, applied in solar thermal power generation, steam engine devices, machines/engines, etc., can solve the problems of power generation efficiency and scale limitation, limit the operation and output of gas steam combined cycle power generation system, and achieve high efficiency Effects of running, reducing fuel consumption, and improving system power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

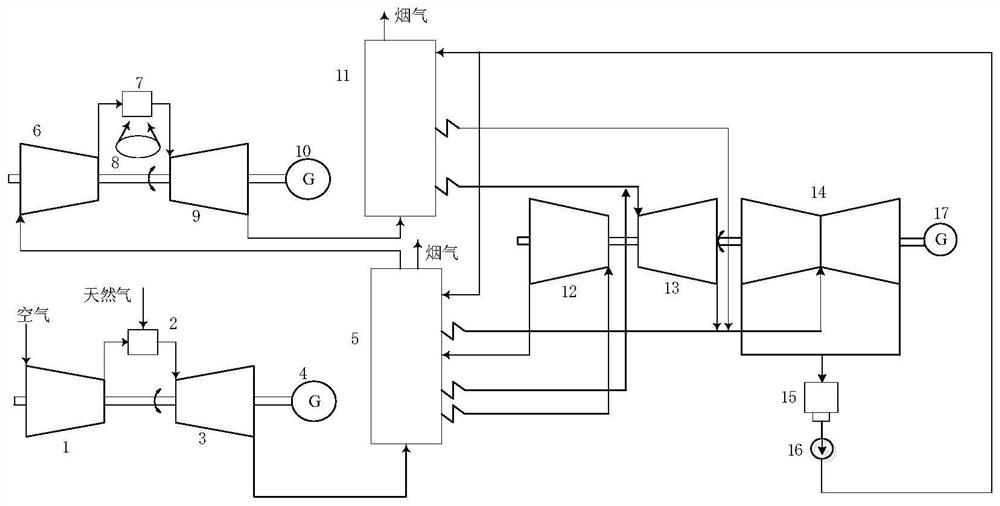

[0012] The present invention will be described below in conjunction with the accompanying drawings.

[0013] Such as figure 1 shown. The present invention proposes a flue gas reheating disc-type photothermal and gas-steam combined cycle power generation system, including a first compressor 1, a combustion chamber 2, a first turbine 3, a first generator 4, and a first waste heat Boiler 5, second compressor 6, dish solar concentrator system 8, solar receiver 7, second turbine 9, second generator 10, second waste heat boiler 11, steam turbine high, medium and low pressure cylinders 12, 13,14, condenser 15, feed water pump 16 and third generator 17.

[0014] The air enters the first compressor and is compressed to a given pressure, and enters the combustor together with fuel natural gas for combustion, and the combusted flue gas (around 1600°C) enters the first turbine to expand and do work, driving the generator to generate electricity. The flue gas (about 600°C) after work en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com