Coke oven coaling flue gas purification system and process

A technology of flue gas purification system and flue gas purification process, which is applied in coking ovens, gas treatment, petroleum industry, etc., can solve the problems of poor purification effect of pollutants such as sulfides and poor operation stability, and achieve long-term Steady-state operation and operation, reducing secondary pollution emissions, and achieving the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

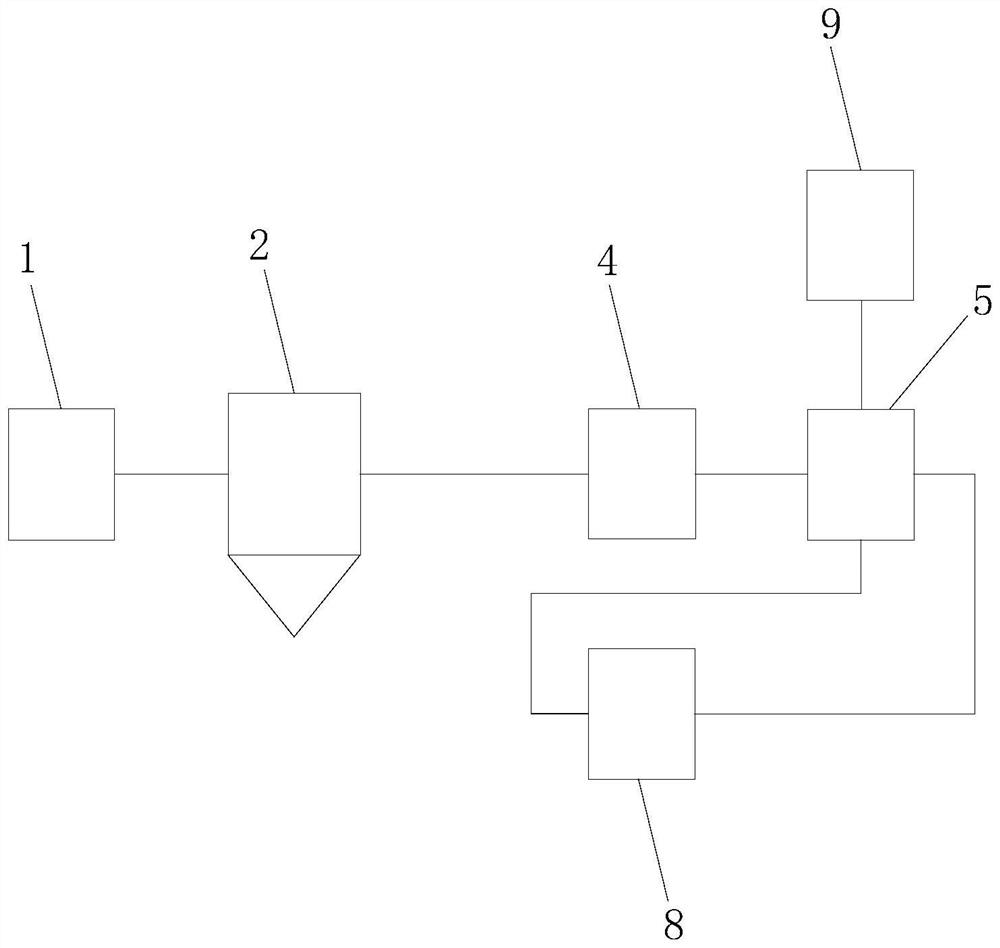

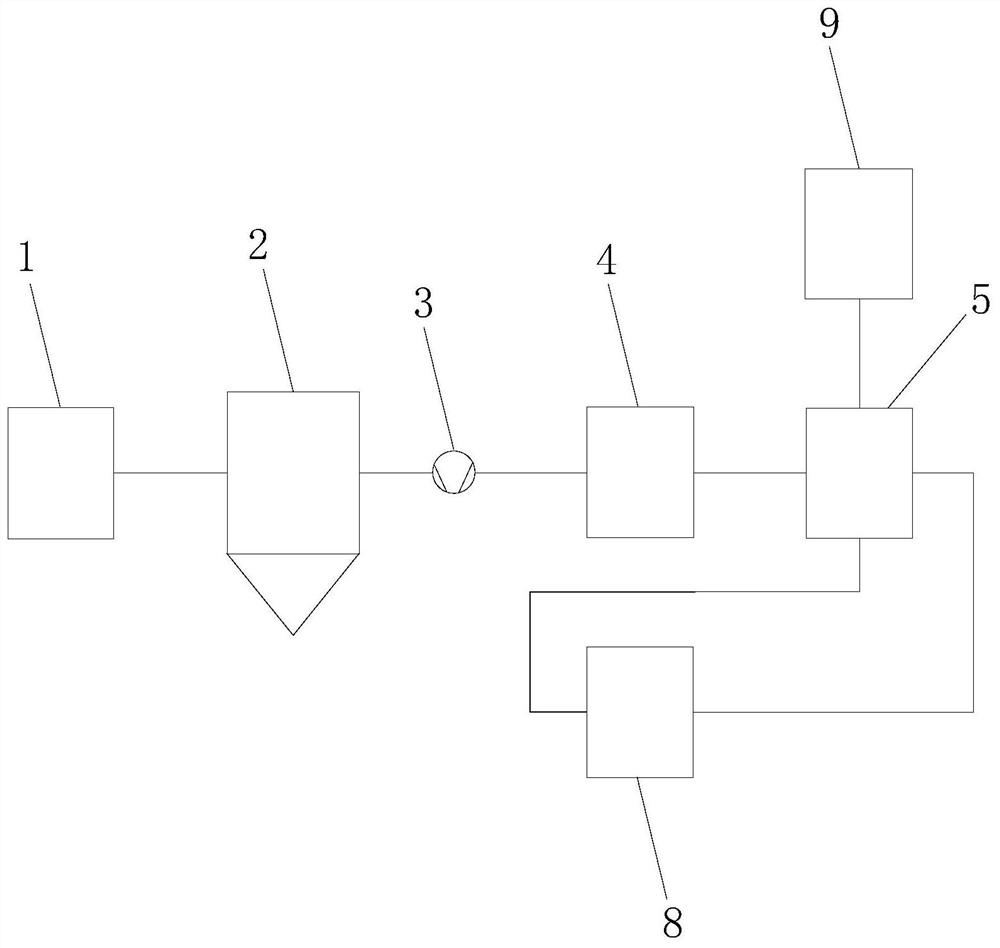

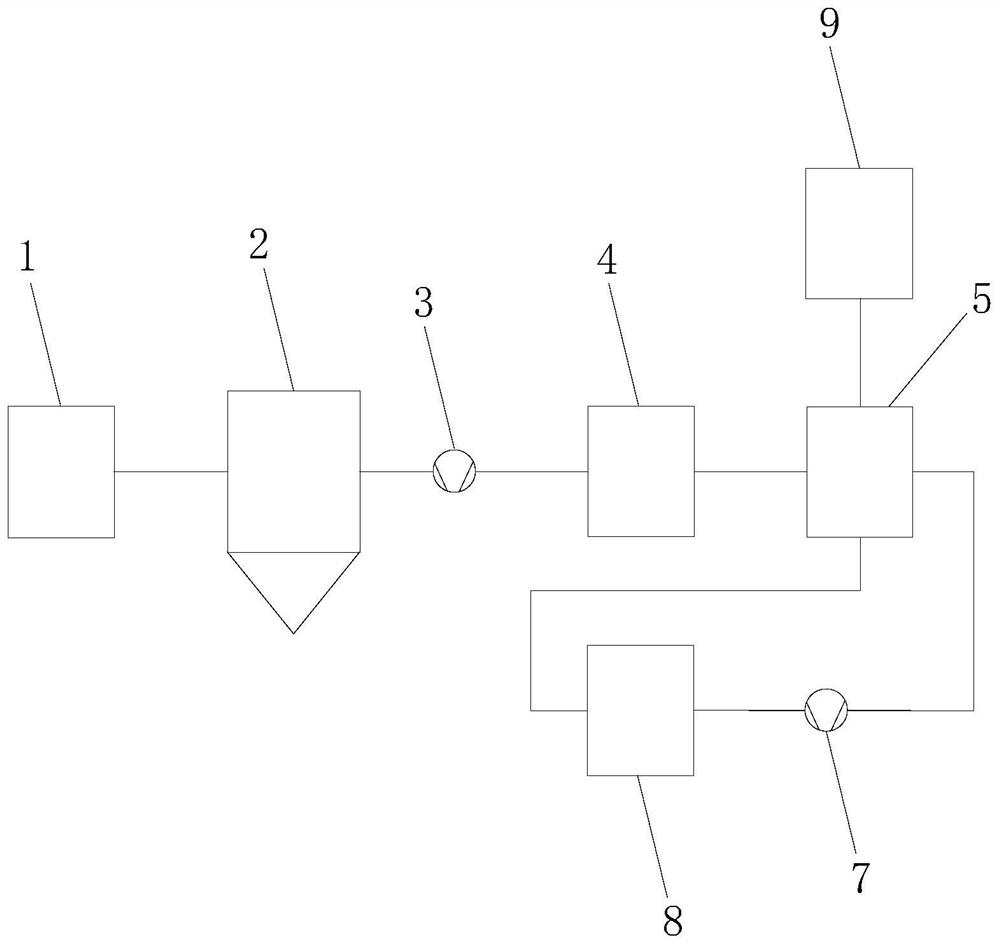

[0047] Such as figure 1As shown, the present invention provides a coke oven coal charging flue gas purification system, which includes a coal charging dust removal device 2, a flue gas cooler 4, an adsorption purification device 5, a regeneration heater 8 and Sulfur recovery device 9, wherein: the air inlet of coal charging and dedusting device 2 is used to connect with the coal charging hole of coke oven 1, the gas outlet of coal charging and dedusting device 2 is connected with the air inlet of flue gas cooler 4, and the flue gas The air outlet of cooler 4 is connected with the air inlet of adsorption purification device 5, the air return port of adsorption purification device 5 is connected with the air inlet of regeneration heater 8, and the air outlet of regeneration heater 8 is connected with the air inlet of adsorption purification device 5. The first gas outlet of the adsorption purification device 5 is connected with the air inlet of the sulfur recovery device 9 .

...

Embodiment 2

[0062] Such as Figure 5 As shown, the present invention provides a coke oven coal charging flue gas purification process, the coke oven coal charging flue gas purification process adopts the above-mentioned coke oven coal charging flue gas purification system, and the coke oven coal charging flue gas purification process includes the following step:

[0063] Step S1: The coke oven coal charging flue gas escapes from the coal charging hole of the coke oven 1, and forms the first air flow, the first air flow is discharged in bursts, the flow rate of the first air flow and the dust and sulfide in the first air flow The concentration of pollutants fluctuates greatly during the coal charging process and the coal charging intermittent process.

[0064] Step S2: The first air flow enters into the coal charging and dust removal device 2. The coal charging and dust removal device 2 is generally composed of a coke oven coal charging ground dust removal station and supporting equipment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com