A high-efficiency needle coke production device and method

A production device and technology of needle coke, which is applied in the field of high-efficiency needle coke production devices, can solve the problems of coke particles that are easy to block equipment pipeline temperature, unevenness, etc., to ensure long-term and stable operation, improve thoroughness, Effect of reducing operating pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

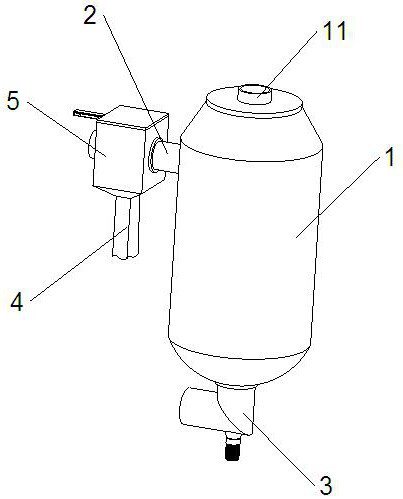

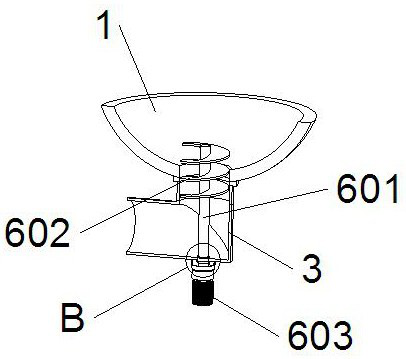

[0039] see Figure 1-Figure 10 As shown, a high-efficiency needle coke production device includes a coking reaction tower 1, and the output end of the coking reaction tower 1 is connected to a purification tower 9 through a pipeline, which is used for thorough purification and fractionation of high-temperature oil and gas to ensure that it enters the fractionation tower 10 There will be no coke particles inside the high-temperature oil and gas. The purification tower 9 is connected to the fractionation tower 10 through pipelines. The bottom of the coking reaction tower 1 is fixed with a discharge pipe 3. The discharge pipe 3 is equipped with a valve opening and closing device, which can be used to control The opening and closing of the discharge pipe 3, the top of the coking reaction tower 1 is provided with a feed pipe 11, the feed pipe 11 is connected to the fractionation tower 10, and is used to transport the high-temperature oil and gas and the refined coal tar soft pitch m...

Embodiment 2

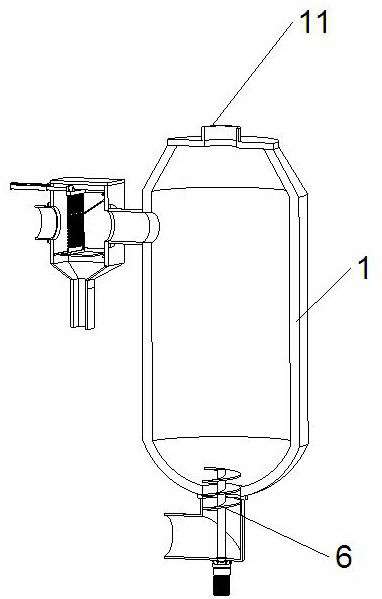

[0042] see figure 1 , Figure 5-Figure 10 As shown, the end of the gas guide pipe 2 away from the coking reaction tower 1 is fixedly installed with a purification mechanism 5. When the high-temperature oil and gas inside the coking reaction tower 1 are exported, a large amount of coke particles are contained in the escaping high-temperature oil and gas, which is likely to affect the stability of the equipment. The purification mechanism 5 is designed to perform preliminary purification treatment on the escaping high-temperature oil and gas through physical methods, thereby reducing the pressure of the rear transportation pipeline and purification tower 9 for slag removal and fractionation. One side of the purification mechanism 5 is symmetrically arranged with the air guide pipe 2 pipeline, the pipeline is used to connect the purification mechanism 5 and the purification tower 9, the bottom end of the purification mechanism 5 is connected with a return pipe 4, and one end of t...

Embodiment 3

[0044] see figure 1 with Figure 7-Figure 10 As shown, the end of the gas guide pipe 2 away from the coking reaction tower 1 is fixedly installed with a purification mechanism 5. When the high-temperature oil and gas inside the coking reaction tower 1 are exported, a large amount of coke particles are contained in the escaping high-temperature oil and gas, which is likely to affect the stability of the equipment. The purification mechanism 5 is designed to perform preliminary purification treatment on the escaping high-temperature oil and gas through physical methods, thereby reducing the pressure of the rear transportation pipeline and purification tower 9 for slag removal and fractionation. One side of the purification mechanism 5 is symmetrically arranged with the air guide pipe 2 pipeline, the pipeline is used to connect the purification mechanism 5 and the purification tower 9, the bottom end of the purification mechanism 5 is connected with a return pipe 4, and one end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com