Protective tube for detecting high-temperature tungsten-rhenium thermocouple

A technology for protecting tubes and thermocouples, applied in thermometers, measuring heat, thermometer testing/calibration, etc., can solve problems such as different atmospheres, pollution calibration, deviation, etc., and achieve the effect of improving calibration conditions and reducing uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

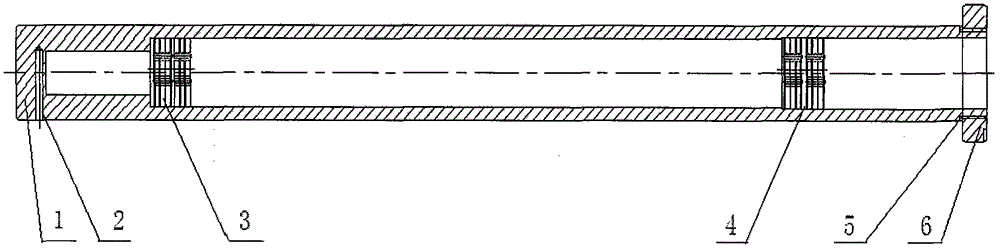

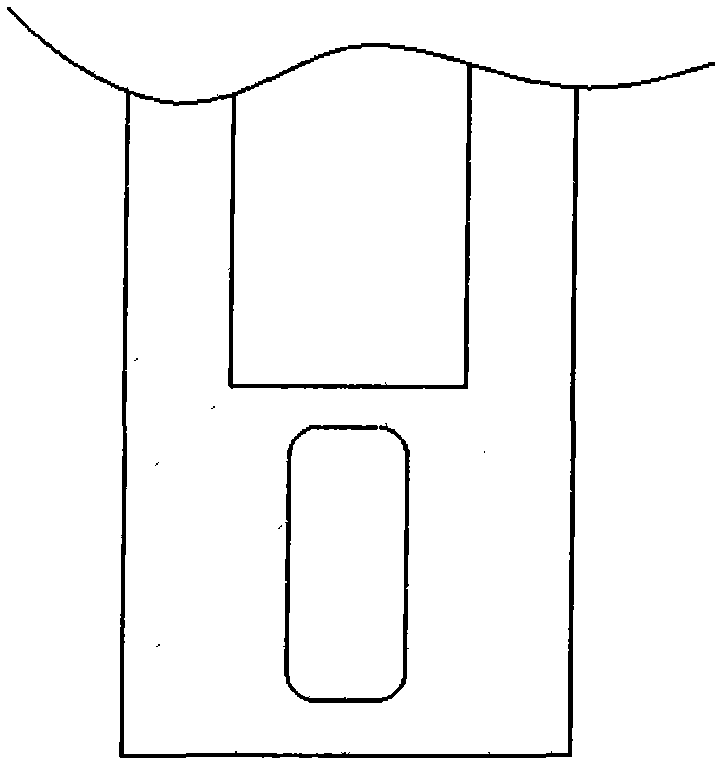

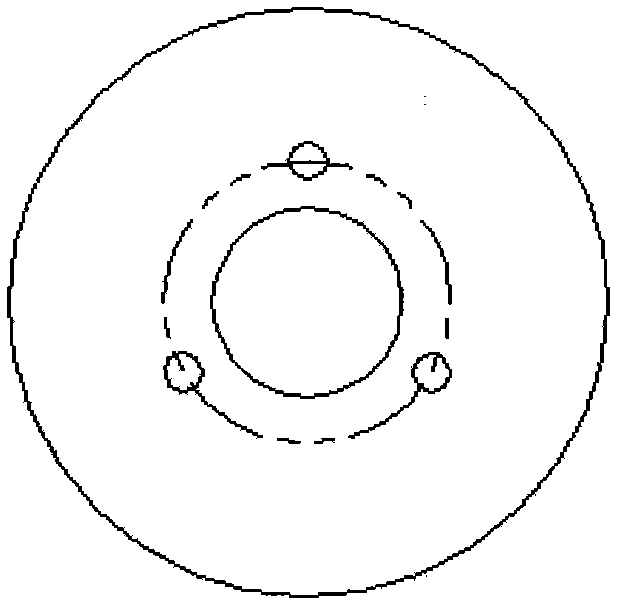

[0023] A protection tube 1 for high-temperature tungsten-rhenium thermocouple verification, including a protection tube 1, a standard radiation test hole 2, an upper tungsten grating 3, a lower tungsten grating 4, a sealing ring 5 and a flange 6; one end of the protection tube 1 It is in a closed state, called the lower end, and the other end is in an open state, called the upper end; the inner wall of the protection tube 1 adopts a two-stage stepped design, and the step near the lower end is higher than the other; the area of the tube wall thickness is the uniform temperature area, It is also the temperature-sensing area of the thermocouple to be calibrated, and other areas are non-uniform temperature areas; there is a standard radiation test hole 2 on the tube wall where the lower end of the protection tube 1 is in contact with the uniform temperature area, and the standard used for calibration is tested through this hole. The temperature of the thermocouple to be calibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com