Pipe orifice correction device capable of achieving rapid alignment and alignment method of pipe orifice correction device

A technology of a correction device and a positive tube, which is applied in the field of quickly aligning the nozzle correction device, can solve the problems of discount of correction effect, not limited to a certain point or a certain orientation, and limit of the lifting direction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

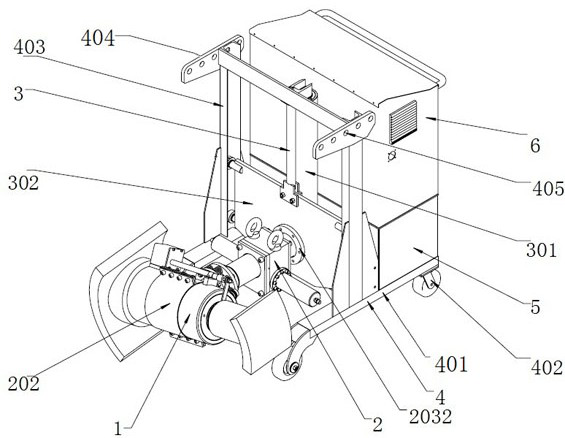

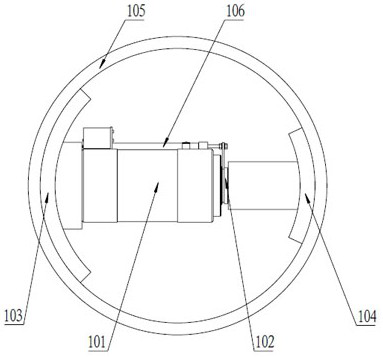

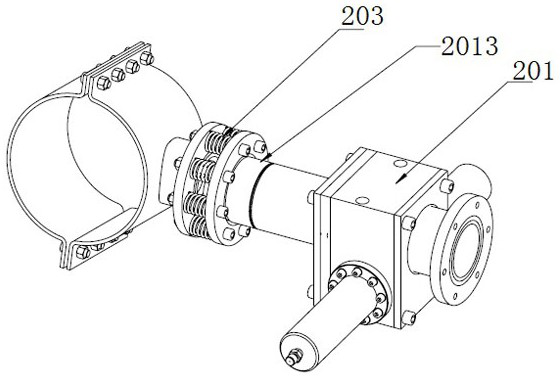

[0030] like figure 1As shown, a nozzle correction device for fast alignment, the nozzle correction machine is composed of a correction hydraulic mechanism 1, a rotating clamping mechanism 2, a lifting mechanism 3, a walking mechanism 4, a hydraulic pump station 5 and a control cabinet 6. The correction hydraulic mechanism 1 is clamped by the clamper 202 at one end of the rotary clamping mechanism 2, and connected with the lifting installation plate 302 of the lifting mechanism 3 through the connecting flange 2032 at the other end. The lifting mechanism 3 is installed inside the traveling mechanism 4, The lifting installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com