A kind of silk cleaning wastewater purification device for textile production

A technology for cleaning wastewater and purifying devices, which is applied in the field of textile production. It can solve problems such as equipment blockage and affect wastewater treatment efficiency, and achieve the effects of improving efficiency, avoiding silk and impurities from falling, and reducing labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

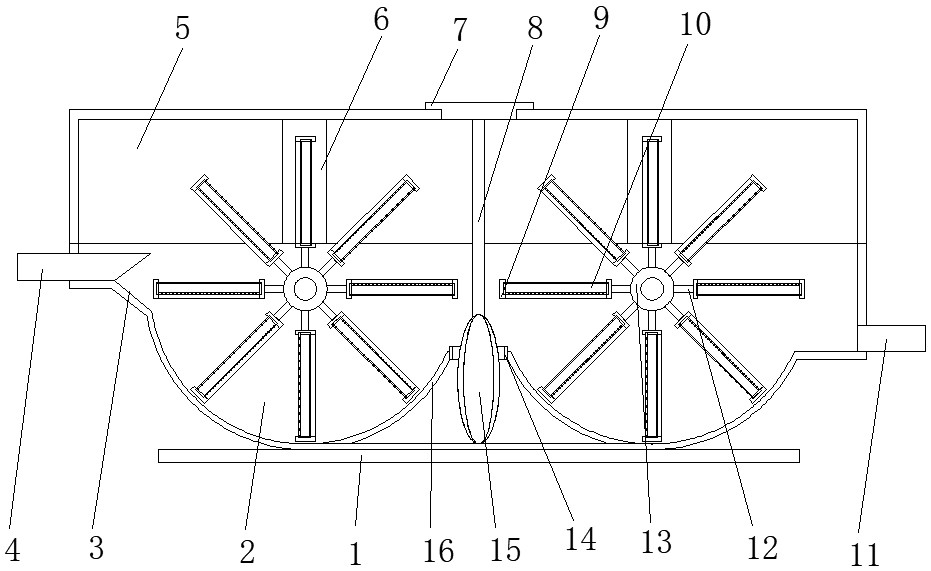

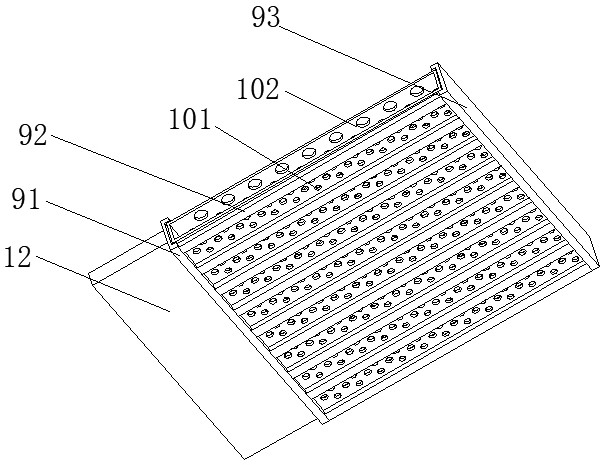

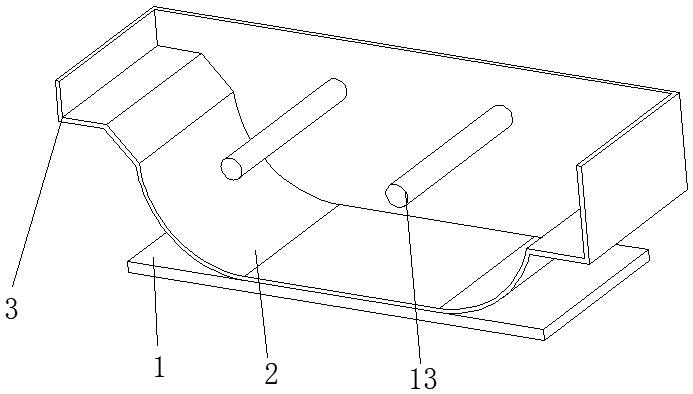

[0027] refer to Figure 1-4 , A device for purifying silk waste water for textile production, comprising a base 1, a casing 3 is fixedly installed on the top of the base 1, a cover 5 is fixedly installed on the top of the casing 3, and both ends of the casing 3 are fixedly installed with The liquid inlet pipe 4 and the liquid discharge pipe 11, and two driving motors are fixedly installed on the side of the casing 3, and a rotating cylinder 13 is installed between the output shaft of the driving motor and the inner wall of the casing 3 through a sealed bearing. There are two processing chambers 2 with cylindrical structures inside, and the rotating cylinder 13 is located inside the processing chamber 2 , a plurality of mounting plates 12 are fixedly installed on the outer side of the rotating cylinder 13 , and the other end of the mounting plate 12 is fixedly installed with a connecting frame 9. A filter mesh box 10 is inserted into the connecting frame 9, two rectangular groo...

Embodiment 2

[0034] refer to Figure 1-3 and Figure 5 , a kind of purifying device for cleaning waste water for textile production. Compared with Embodiment 1, the auxiliary filter net pocket 15 is a mesh cylinder 152 with an elliptical columnar structure, and the auxiliary filter net pocket 15 is made of a flexible material. The mesh cylinder 152 is made of an elliptical columnar structure. During installation, the secondary filter net pocket 15 can be squeezed by changing the height of the isolation plate 8 to control the width of the waste water circulation on both sides, and the secondary filter net pocket 15 can be changed when it is squeezed. The mesh size can control the filtration rate and improve the purification quality. At the same time, it is convenient to store the filtered impurities in the interior of the cylindrical structure, which further improves the convenience of device cleaning;

[0035] Both sides of the mesh cylinder body 152 are welded with a plurality of soft cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com