Integrated inductor forming equipment based on inductor processing

A molding equipment and integrated technology, applied in the manufacture of inductors/transformers/magnets, circuits, electrical components, etc., can solve problems such as speed mismatch, low product precision, and low aesthetics, and achieve highly consistent appearance and compact space layout , the effect of convenient multi-line layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

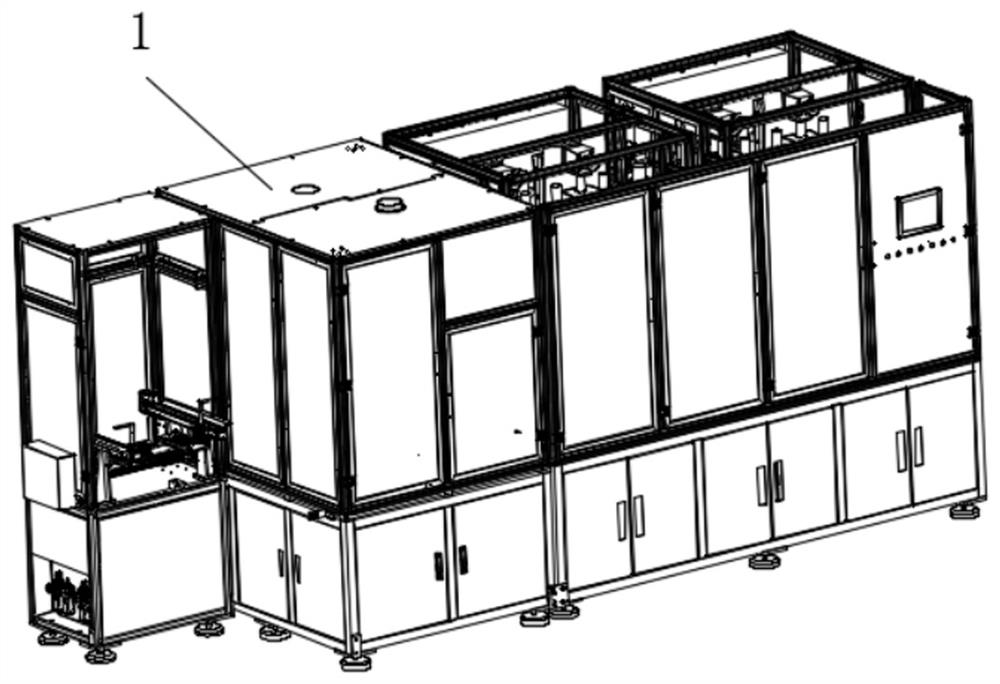

[0037] Embodiment 1: as Figure 1-10 , the present invention provides a technical solution: comprising:

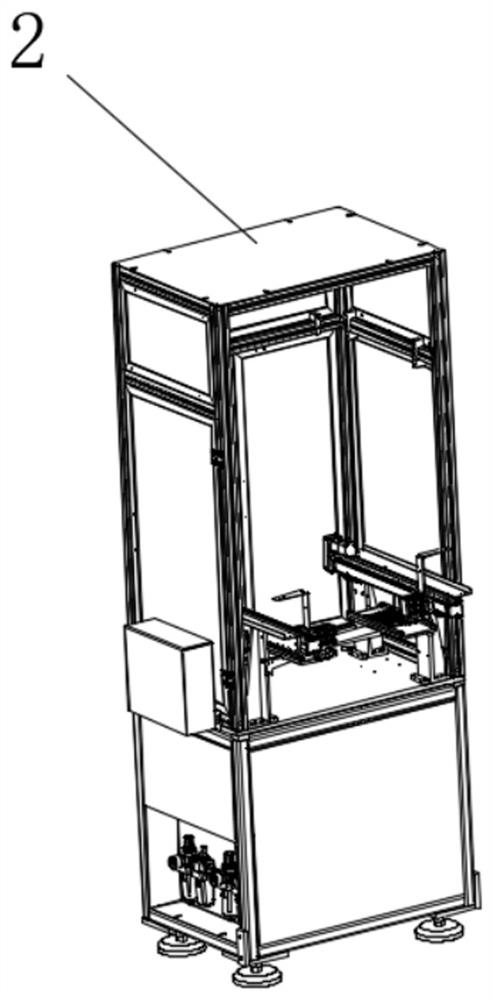

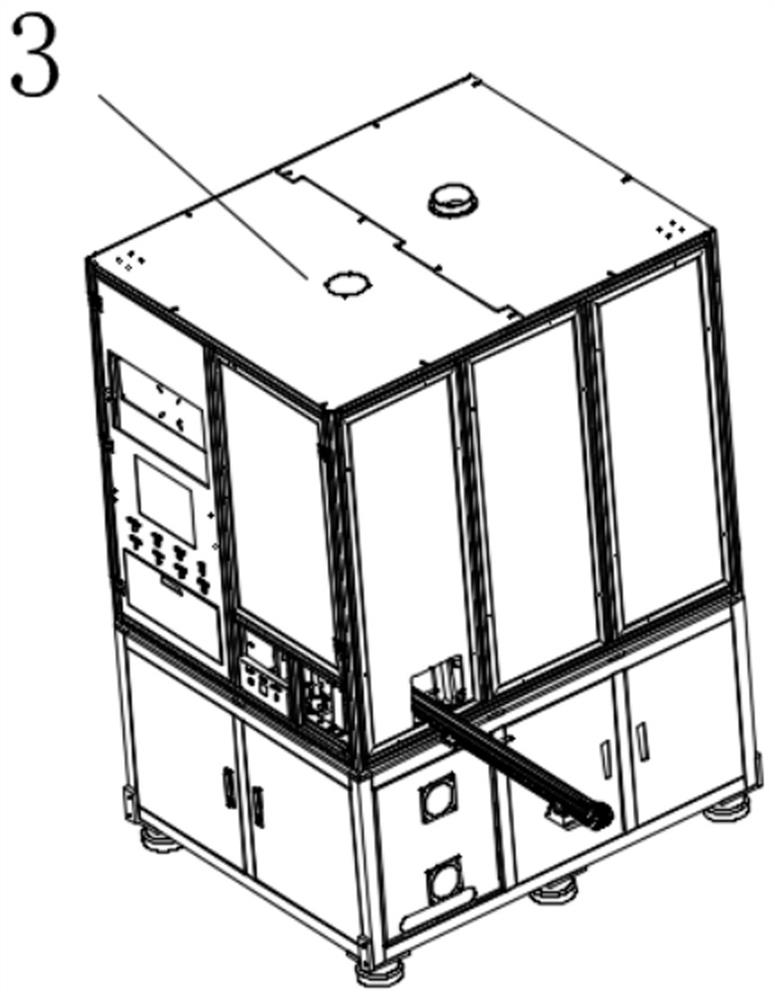

[0038] Hot pressing automatic line 1, hot pressing automatic line 1 includes feeding machine 2, powder filling machine 3, manipulator feeding machine 4 and hot pressing packaging machine 5;

[0039] The loading machine 2 includes a lower frame large plate 201, a first cylinder 202, a first driving mechanism 203, a second cylinder 204, a second driving mechanism 205, a first hot-pressing middle template 206 and an air conditioning combination 207;

[0040] The powder filling machine 3 includes a magazine support plate 301, a cooling shield 302, a rail frame plate 303, a long conveying module 304, a powder filling detection lens support plate 305, a finished product detection lens support plate 306, a 3D lens 307, and a waste cylinder support plate 308, finished product conveying module 309, booster cylinder 310 and powder filling module bottom plate 311;

[0041] The mani...

Embodiment 2

[0044] Embodiment 2: as Figure 1-10 , the present invention provides a kind of technical scheme: comprising:

[0045] Hot pressing automatic line 1, hot pressing automatic line 1 includes feeding machine 2, powder filling machine 3, manipulator feeding machine 4 and hot pressing packaging machine 5;

[0046] The loading machine 2 includes a lower frame large plate 201, a first cylinder 202, a first driving mechanism 203, a second cylinder 204, a second driving mechanism 205, a first hot-pressing middle template 206 and an air conditioning combination 207;

[0047] The powder filling machine 3 includes a magazine support plate 301, a cooling shield 302, a rail frame plate 303, a long conveying module 304, a powder filling detection lens support plate 305, a finished product detection lens support plate 306, a 3D lens 307, and a waste cylinder support plate 308, finished product conveying module 309, booster cylinder 310 and powder filling module bottom plate 311;

[0048] Th...

Embodiment 3

[0053] Embodiment 3: as Figure 1-10 , the present invention provides a kind of technical scheme: comprising:

[0054] Hot pressing automatic line 1, hot pressing automatic line 1 includes feeding machine 2, powder filling machine 3, manipulator feeding machine 4 and hot pressing packaging machine 5;

[0055] The loading machine 2 includes a lower frame large plate 201, a first cylinder 202, a first driving mechanism 203, a second cylinder 204, a second driving mechanism 205, a first hot-pressing middle template 206 and an air conditioning combination 207;

[0056] The powder filling machine 3 includes a magazine support plate 301, a cooling shield 302, a rail frame plate 303, a long conveying module 304, a powder filling detection lens support plate 305, a finished product detection lens support plate 306, a 3D lens 307, and a waste cylinder support plate 308, finished product conveying module 309, booster cylinder 310 and powder filling module bottom plate 311;

[0057] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com