Processing method of wastewater in the sebacic acid production and special extractor thereof

A technology for wastewater treatment and extraction device, which is applied in the process of wastewater treatment, extraction water/sewage treatment, neutralization water/sewage treatment, etc. It can solve the problem of short resin use cycle, large backwash workload, and large resin consumption. and other problems to achieve the effect of reducing processing costs, improving production levels and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

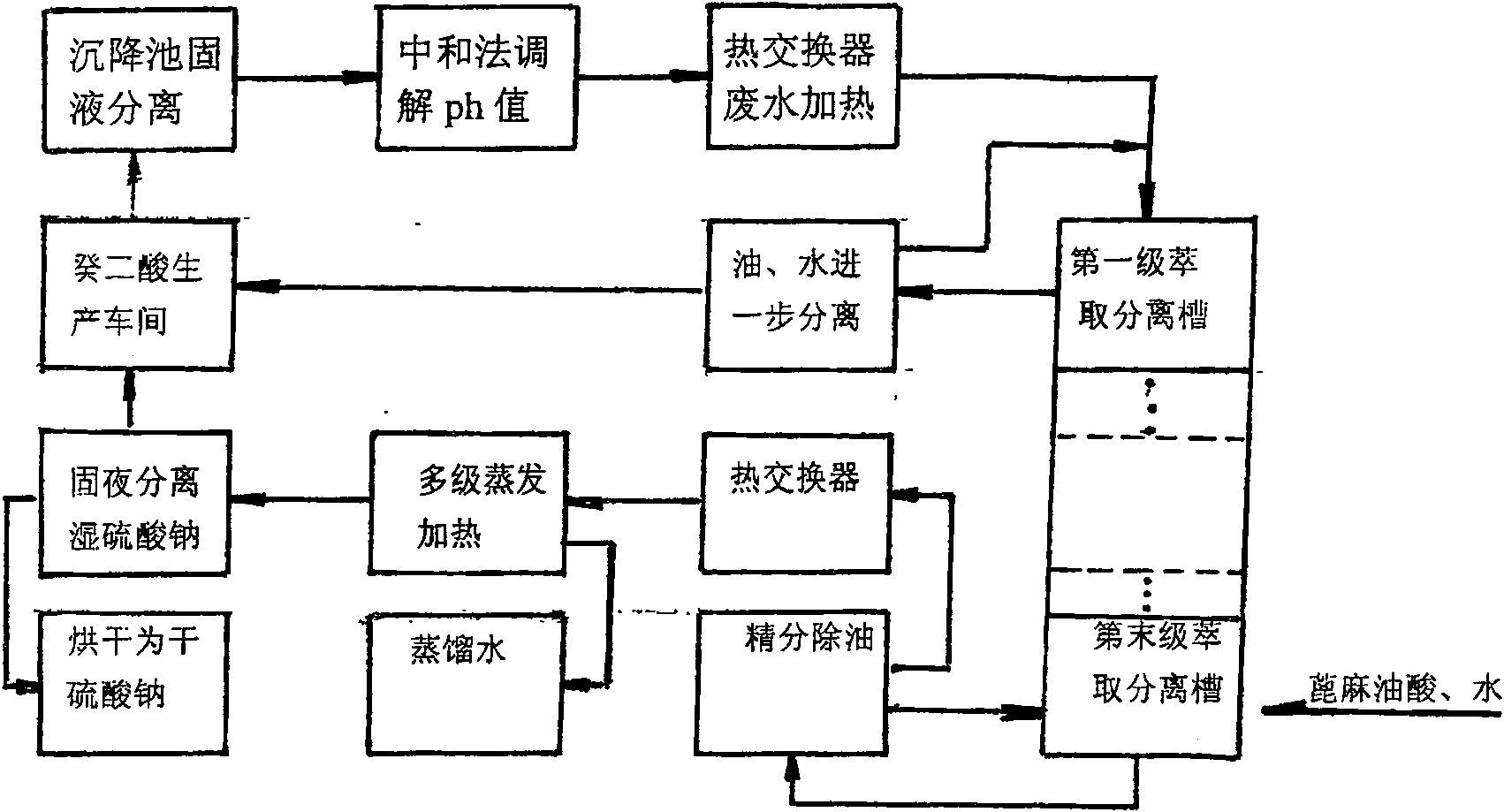

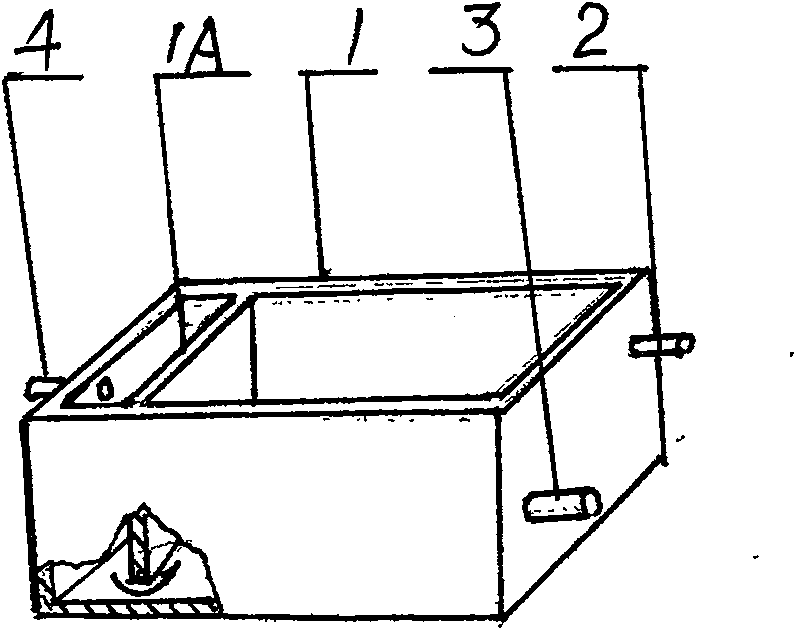

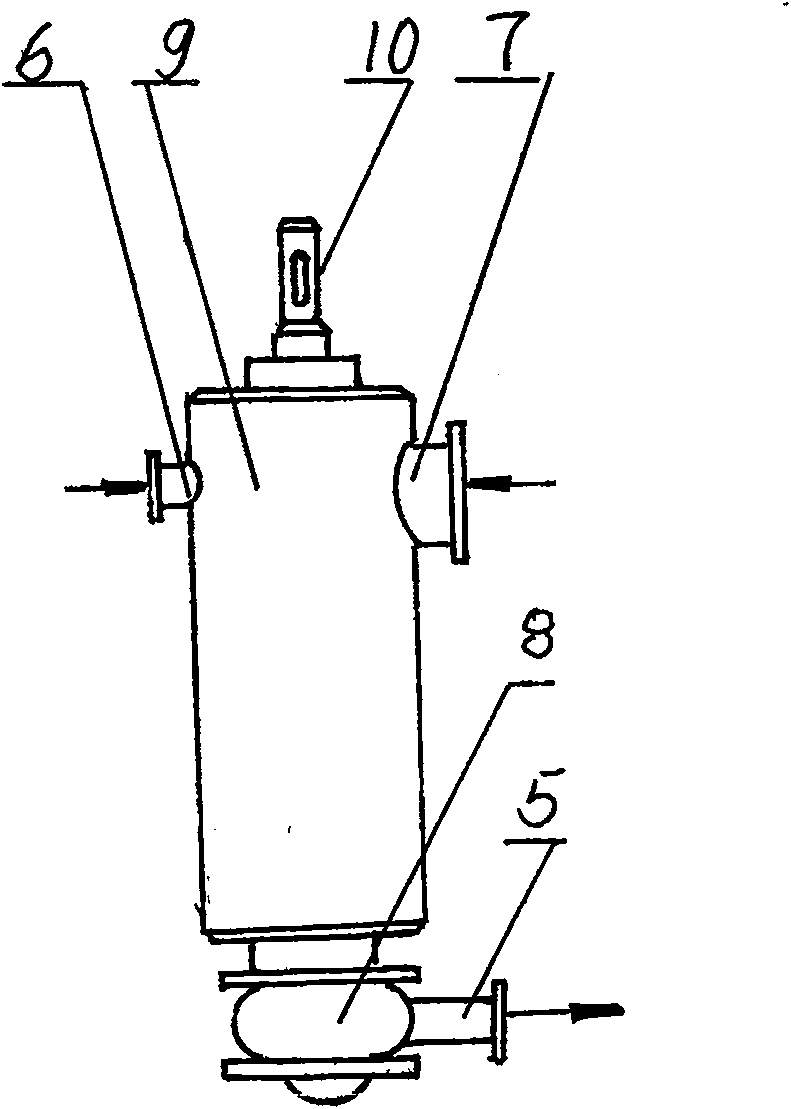

[0016] Referring to the accompanying drawings, it can be clearly seen that the core of the present invention is the use of ricinoleic acid as the extractant of the main forbidden phenol and the matching of a feasible treatment method, as well as the provision of an ideal special-purpose multi-stage extraction tank device.

[0017] The treatment method includes solid-liquid separation in a settling tank, adjustment of Ph value by neutralization method, extraction of forbidden substances by extraction agent, separation of forbidden substances and discharge water, and the key lies in using ricinoleic acid as an extraction agent to extract and separate Forbidden discharge phenol in sebacic acid production wastewater, and adopts specific steps of mixing and reusing extractant and extract.

[0018] In the following specific implementation instructions, what is referred to is the relevant technical conditions given by the amount of wastewater produced under the production scale of 1-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com