Method for extracting and separating thorium ions by using ion liquid extraction-supercritical CO2 reverse extraction technology

A technology of ionic liquid and thorium ion, which is applied in the field of nuclear fuel cycle to achieve the effect of improving extraction capacity, broad application prospect and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

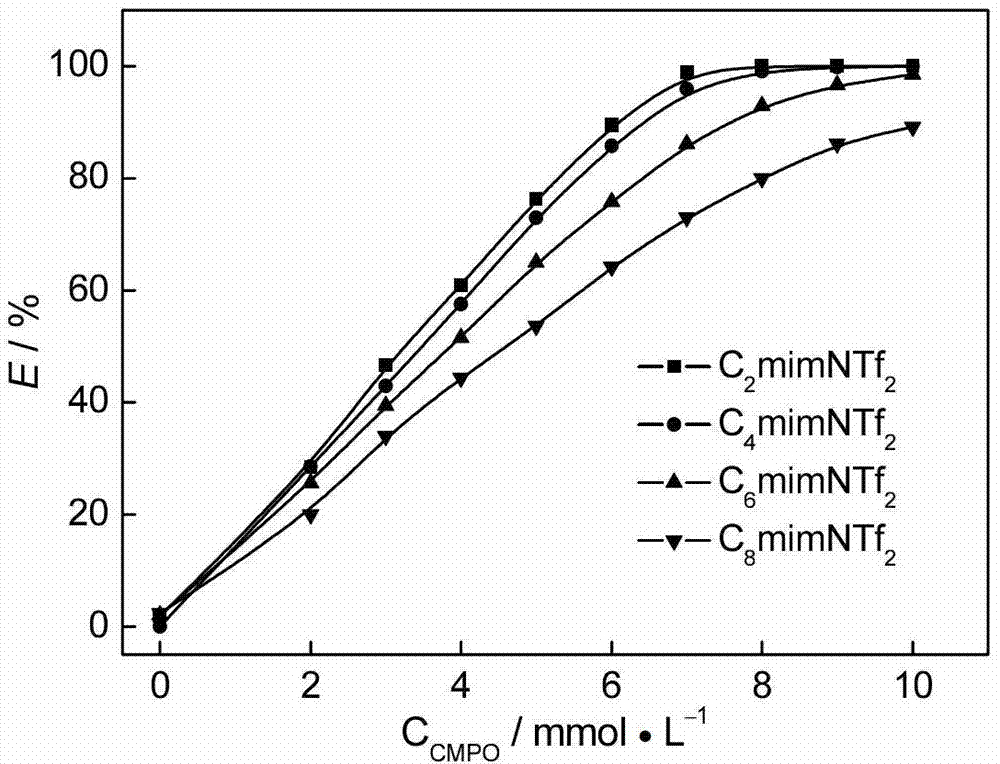

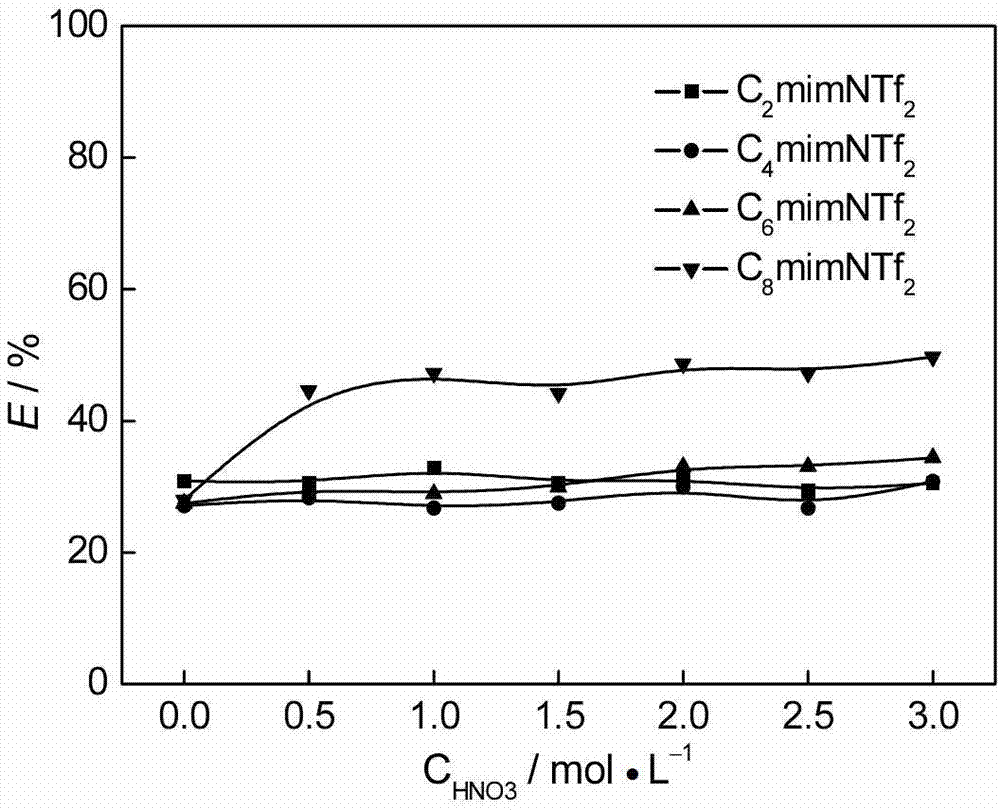

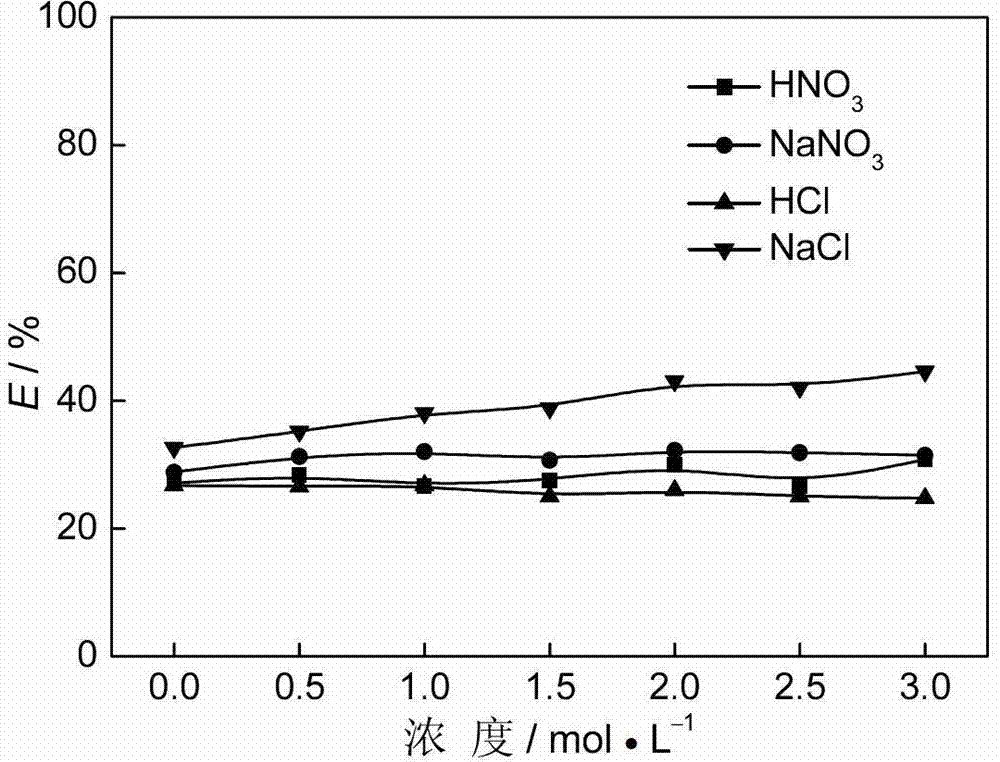

[0028] Embodiment 1, ionic liquid extracts thorium ion

[0029] When carrying out the extraction experiment, take 0.5ml of ionic liquid containing a certain amount of CMPO (purchased from STREM, USA, product number: 15-3500) and 0.5ml of an aqueous phase containing a certain amount of thorium ions or an aqueous phase containing thorium ions and other ions After shaking for at least 2 hours, the phases were separated by centrifugation, and the upper aqueous phase was taken to analyze the concentration of thorium ions (arsenazo III method or inductively coupled plasma atomic emission spectrometry ICP-AES), and the concentration of thorium ions extracted into the ionic liquid phase was determined by subtraction method Obtained, thus obtain the extraction rate E or distribution ratio D.

[0030]CMPO is used as an extractant to extract thorium ions in the aqueous phase: C containing 0.006mol / L CMPO 2 mimNTf 2 It can quantitatively extract 0.002 mol / L thorium ions from the aqueous...

Embodiment 2

[0034] Embodiment 2, supercritical CO 2 Stripping CMPO / C n mimNTf 2 -Th 4+ Thorium ions in the system

[0035] In the stripping experiment, centrifuge the Th-enriched ionic liquid phase from the water phase, take the ionic liquid phase and place it in a supercritical extraction kettle, set the temperature and pressure of the reaction, select the dynamic extraction mode, and add the corresponding entrainer conduct experiment. After the stripping was completed, the ionic liquid sample was taken for microwave digestion, and the concentration of residual metal ions was measured by ICP-AES. The stripping efficiency was obtained by subtraction method from the known total concentration of metal ions in the ionic liquid phase.

[0036] Supercritical CO 2 Stripping CMPO / C n mimNTf 2 / Th 4+ The invention of the system: with CMPO / C 2 mimNTf 2 / Th 4+ Take the system as an example, under the conditions of 200atm and 40°C, TOPO / acetonitrile solution is selected as the entrainer. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com