Zero-emission cooking fume purifying treatment and air conditioning integrated stove

A technology of oil fume purification and discharge, applied in the field of integrated stoves, can solve the problems of poor oil fume separation effect of integrated stoves, low recycling rate of oil pollution, inconvenient installation of integrated stoves, etc., to achieve improved air quality, good practicability, and high purification efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

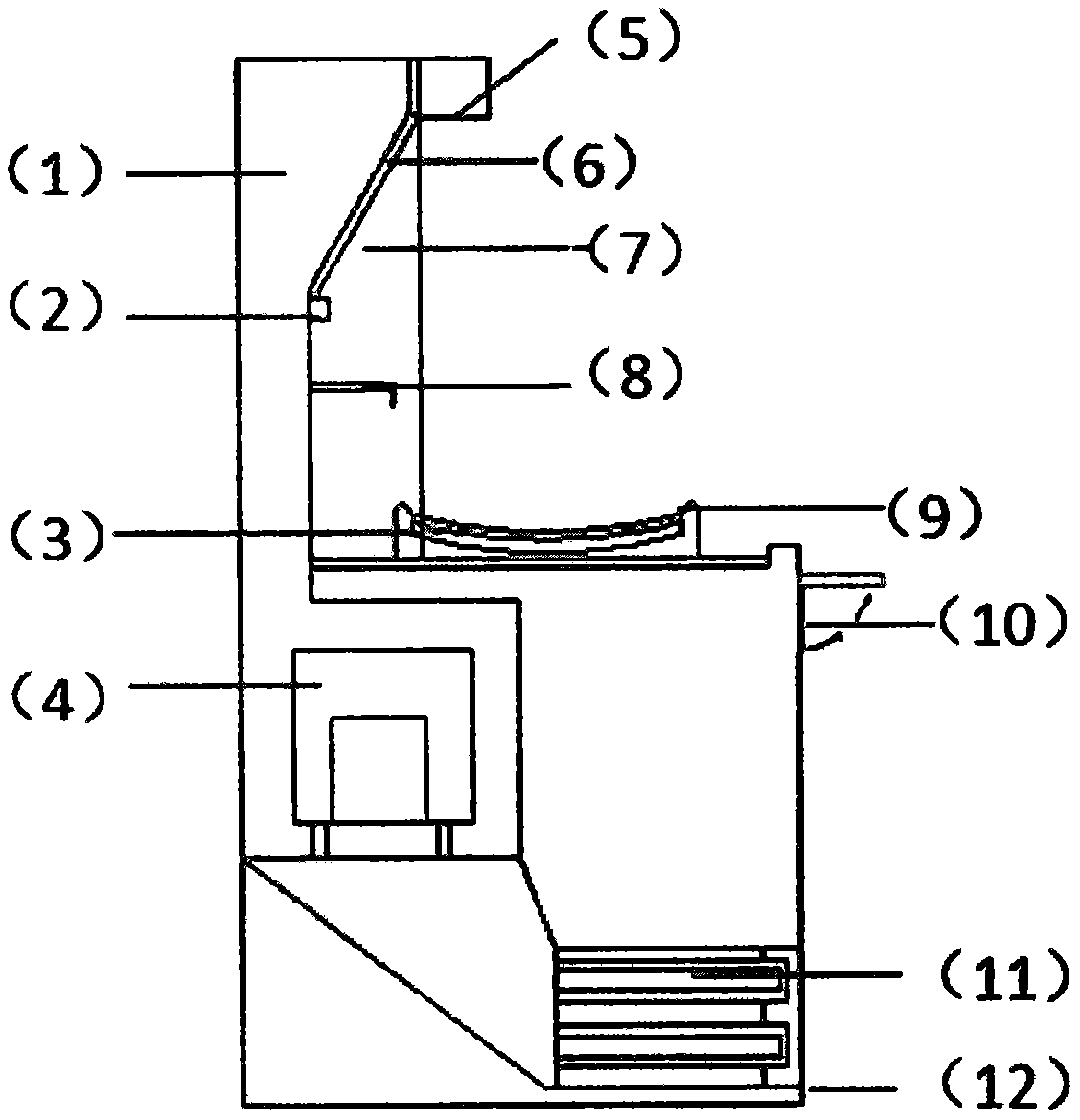

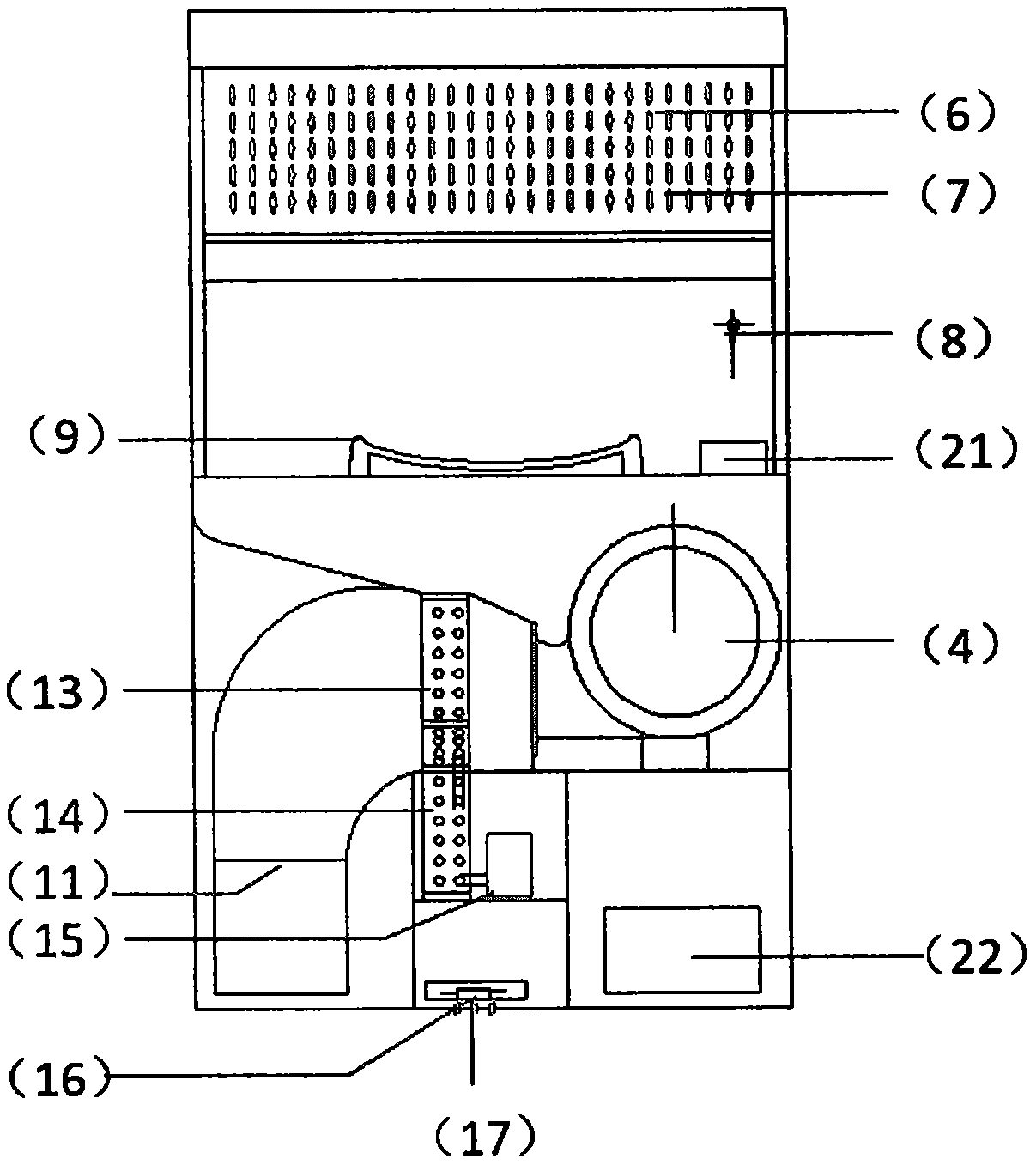

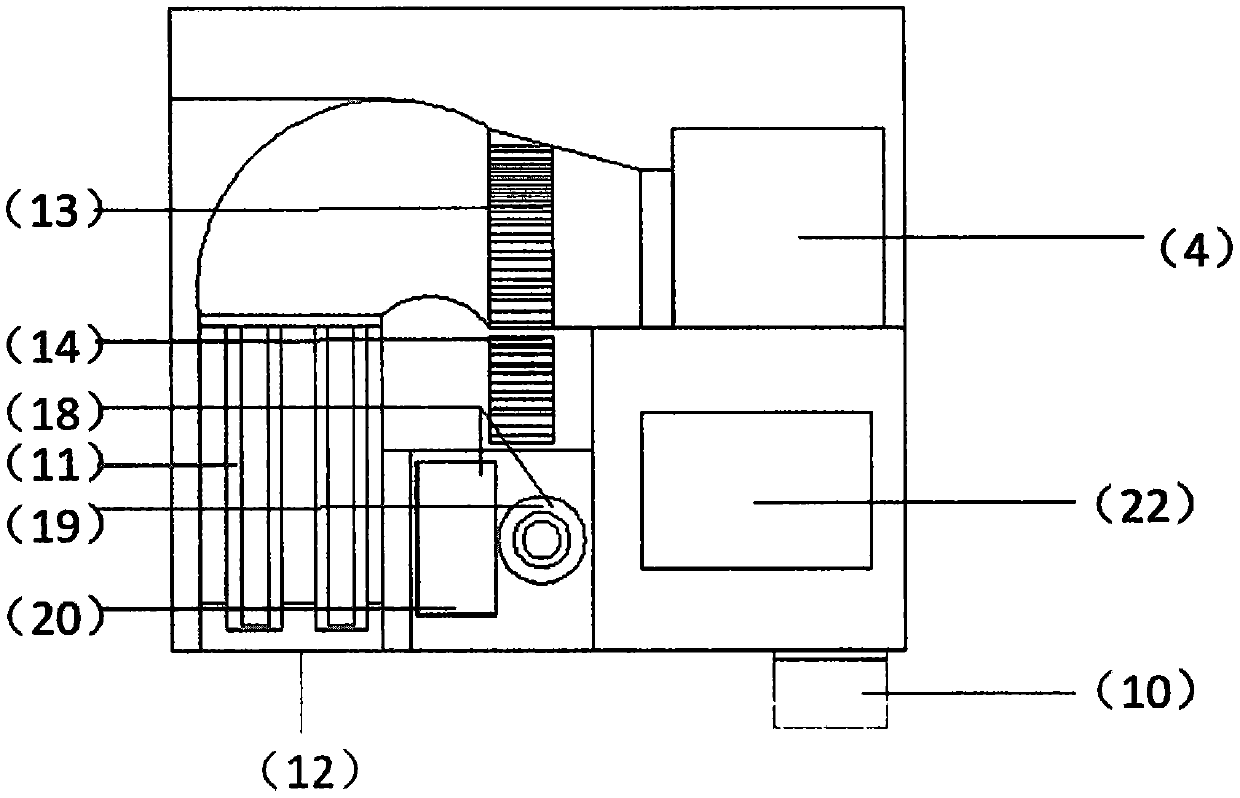

[0032] Such as Figure 1 to Figure 3 As shown, the patent of the present invention provides a zero-emission oil fume purification treatment air-conditioning integrated stove. Including the stove body and the stove top (not shown in the picture) are all integrated and installed. The lighting lamp (5) is located at the upper edge of the oil fume separator (6) and is used for cooking lighting. The cooktop (not shown) is connected to the faucet (8) and the tail support (21). The cooktop (not shown) is decorated with glass-ceramic (9). The cooktop heating system adopts magnetoelectric heating with built-in heating coils (3).

[0033] The cooktop (not shown in the figure) is 80 cm high, the oil fume isolator (6) is installed above the horizontal plane of the cooktop, the isolator (6) and the air suction port (7) are integrated, and the oil tank is installed on the lower edge of the isolator (6) (2), the inner space of the isolator (6) is an air groove (1), and the air groove (1) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com