Oil smoke separator of kitchen range hood

A technology of oil fume separator and range hood, which is applied in the field of kitchen range hoods, can solve the problems that the separation rate of oil fume is not very high, which affects the working performance of the range hood for environmental cleaning, and achieves easy disassembly and assembly, convenient cleaning of oil stains, and cleansing of oil fumes. The effect of high separation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

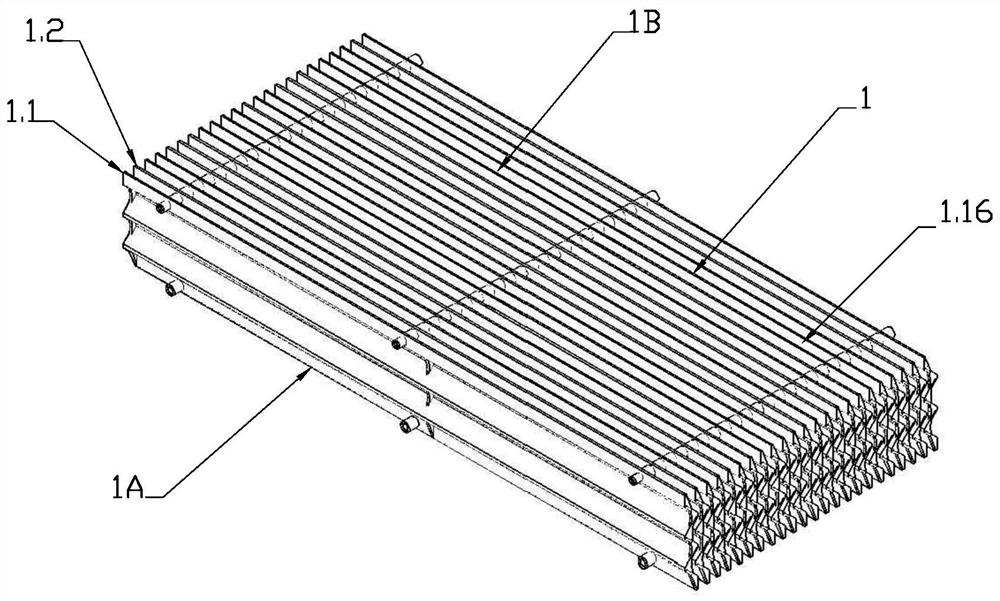

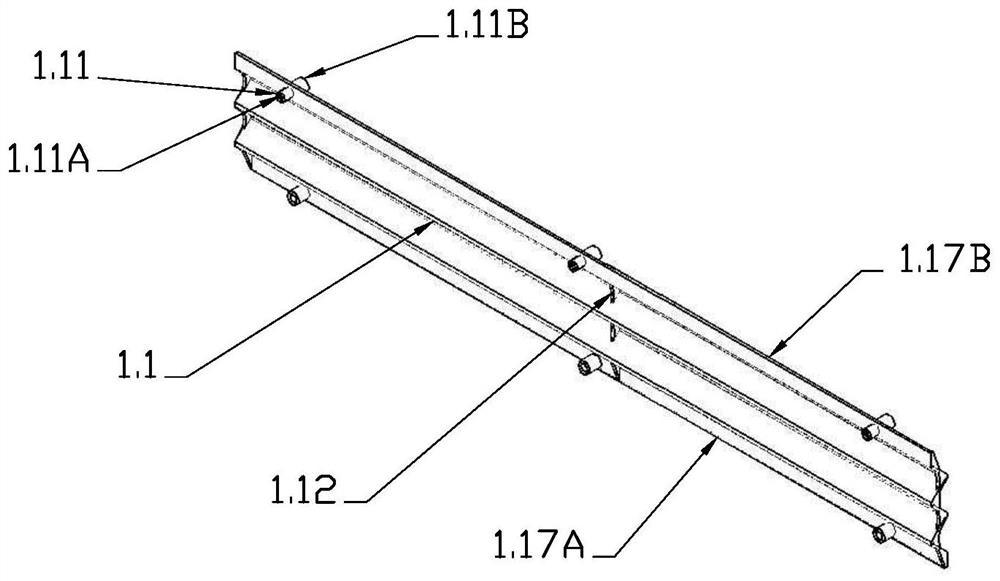

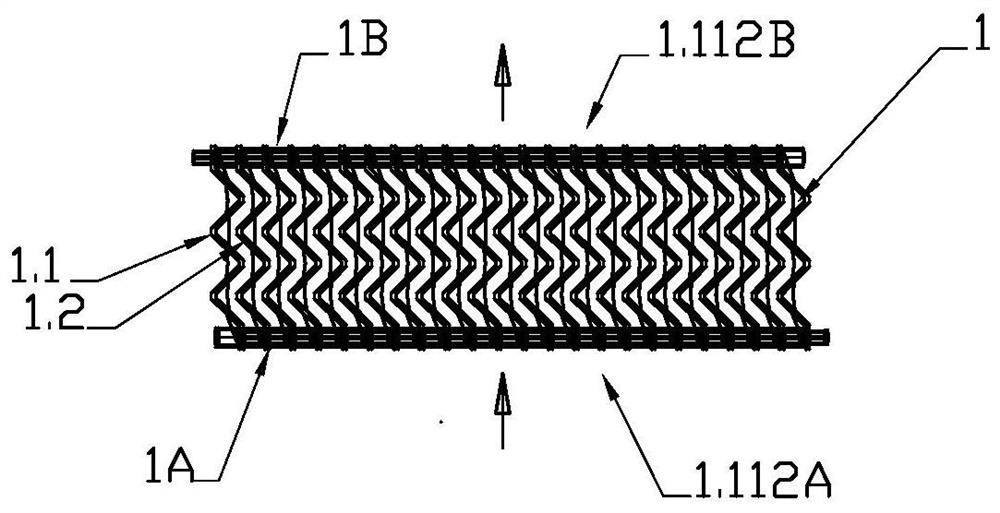

[0041] Figure 1-Figure 5 It is a structural schematic diagram of the first embodiment of the present invention. in figure 1 It is a three-dimensional schematic diagram of the overall structure, image 3 is the main view of the overall structure ( image 3 The direction of the middle arrow is the direction of smoke flow); figure 2 is a schematic diagram of the local structure, Figure 4 An enlarged schematic diagram (three-dimensional view) of the local structure, Figure 5 Schematic diagram of the design parameters for the ventilation compartment ( Figure 5 The direction of the middle arrow is the direction of smoke flow). As shown in the figure, in this example, an oil fume separator for a kitchen range hood is a diversion grid 1 formed by alignment and serial connection of diversion plates 1.1 one by one, and the left and right sides of diversion plates 1.1 The wall is a wavy surface, and the cross-section of the diversion leaf 1.1 is a wave structure. The left and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com