Polyphosphazene microsphere-based phenolic resin molding plastic additive and preparation method thereof

A phenolic resin and molding compound technology, which is applied in the field of phenolic resin molding compound additives based on polyphosphazene microspheres and phenolic resin molding compound additives, can solve problems such as poor compatibility and easy agglomeration of microspheres, and achieve increased compatibility. properties and adhesion, improved mechanical properties, improved heat resistance and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

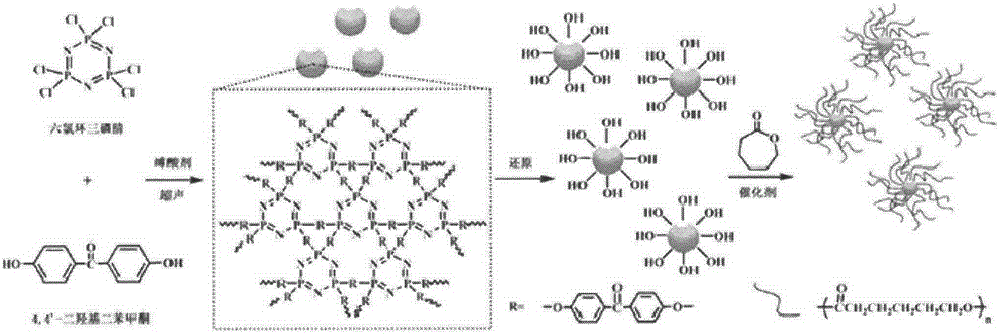

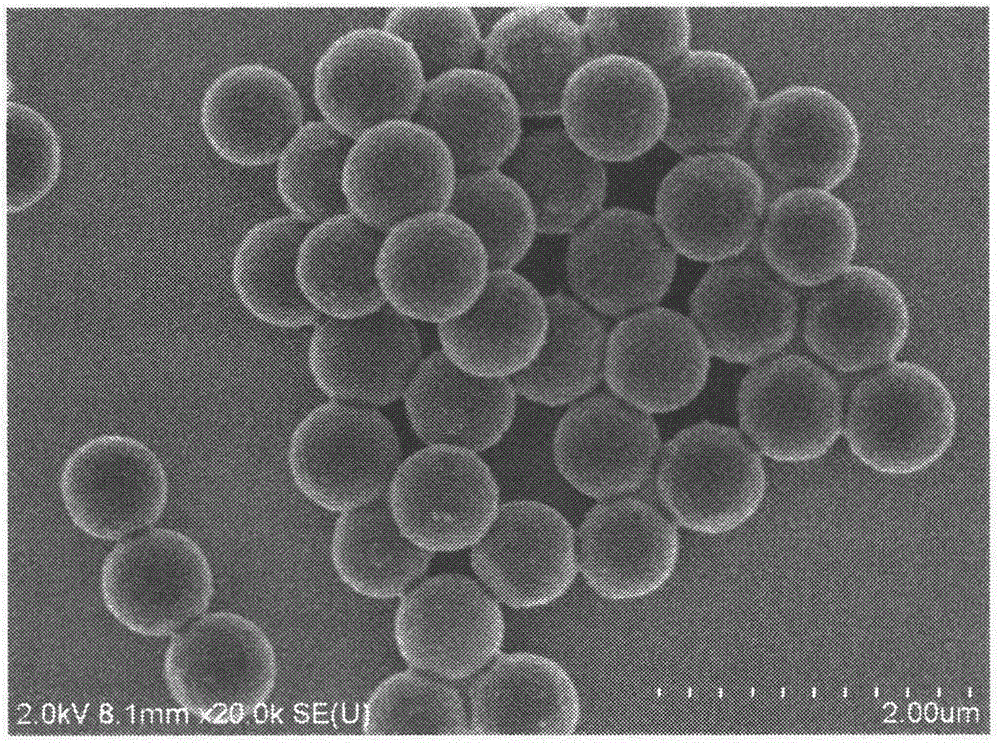

[0024] Weigh 0.2g of hexachlorocyclotriphosphazene and 0.37g of 4,4'-dihydroxybenzophenone, put them in a 250mL round bottom flask, add 100mL of acetonitrile solvent, ultrasonically in a water bath for about 5min until completely dissolved, then add 1mL of triethyl Amines were reacted with ultrasound (200W, 40kHz) in a water bath at 50°C for 5 hours. After the reaction, the solvent was removed by centrifugation, and the precipitate was alternately washed three times with deionized water and acetone, and then the product was dried in a vacuum oven at 45° C. for 24 hours to obtain a white solid powder.

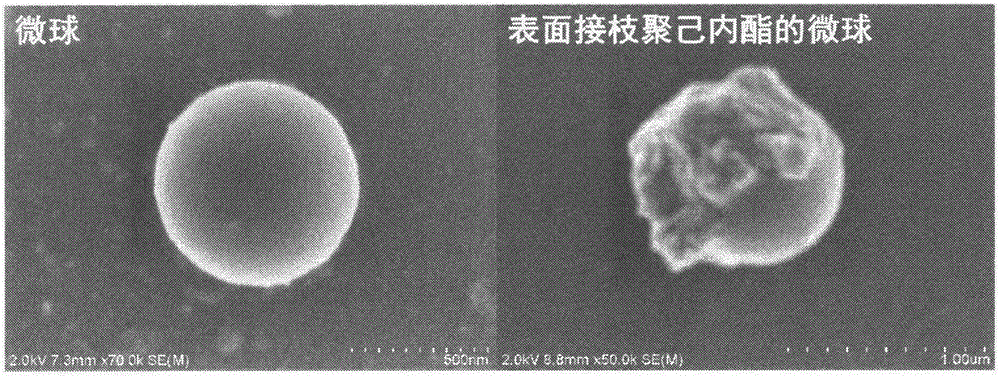

[0025] Put the obtained microspheres into a 250mL round-bottomed flask with a stirring bar, add 100mL of methanol, ultrasonicate the water bath for about 5min until the white powder is uniformly dispersed, then weigh 2g of sodium borohydride, add in batches, and react at room temperature for 24h . After the reaction, the solvent was removed by centrifugation, the precipitate wa...

Embodiment 2

[0029] Weigh 0.2g of hexachlorocyclotriphosphazene and 0.37g of 4,4'-dihydroxybenzophenone, put them in a 250mL round bottom flask, add 100mL of acetone solvent, ultrasonicate in a water bath for about 5min until completely dissolved, then add 1mL of triethyl Amines were reacted with ultrasound (200W, 40kHz) in a water bath at 50°C for 5 hours. After the reaction, the solvent was removed by centrifugation, and the precipitate was alternately washed three times with deionized water and acetone, and then the product was dried in a vacuum oven at 45° C. for 24 hours to obtain a white solid powder.

[0030] Put the obtained microspheres into a 250mL round-bottomed flask with a stirring bar, add 100mL of methanol, ultrasonicate the water bath for about 5min until the white powder is uniformly dispersed, then weigh 2g of sodium borohydride, add in batches, and react at room temperature for 24h . After the reaction, the solvent was removed by centrifugation, the precipitate was wash...

Embodiment 3

[0034] Weigh 0.2g of hexachlorocyclotriphosphazene and 0.37g of 4,4'-dihydroxybenzophenone, put them in a 250mL round bottom flask, add 100mL of acetonitrile solvent, ultrasonicate in a water bath for about 5min until completely dissolved, then add 1mL of tributyl Amines were reacted with ultrasound (200W, 40kHz) in a water bath at 50°C for 5 hours. After the reaction, the solvent was removed by centrifugation, and the precipitate was alternately washed three times with deionized water and acetone, and then the product was dried in a vacuum oven at 45° C. for 24 hours to obtain a white solid powder.

[0035] Put the obtained microspheres into a 250mL round-bottomed flask with a stirring bar, add 100mL of methanol, ultrasonicate the water bath for about 5min until the white powder is uniformly dispersed, then weigh 2g of sodium borohydride, add in batches, and react at room temperature for 24h . After the reaction, the solvent was removed by centrifugation, the precipitate was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com