Porous diaphragm, preparation method of porous diaphragm as well as lithium ion battery

A technology of porous diaphragm and pore size, which is applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve the problems of poor wettability of porous diaphragm and unfavorable lithium battery cycle performance, etc., achieve good heat resistance, avoid battery explosion and burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a preparation method of a porous diaphragm, comprising the following steps:

[0038] A) Dissolving the heat-resistant polymer in an organic solvent to obtain a casting solution, the heat-resistant polymer includes polyphosphazene, polysulfone, polyethersulfone, polyetheretherketone, polyetheramide and polyacrylonitrile one or more of them;

[0039] B) extruding the casting solution obtained in step A) to obtain a liquid precursor film;

[0040]C) immersing the liquid precursor film obtained in step B) into a non-solvent for curing to obtain a solid precursor film;

[0041] D) Drying the solid precursor film in step C) to obtain a porous diaphragm.

[0042] In the invention, the heat-resistant polymer is dissolved in an organic solvent to obtain a casting liquid. In order to make the resulting porous diaphragm have better mechanical strength, the present invention preferably uses a cross-linking agent to modify the heat-resistant po...

Embodiment 1

[0082] Dissolving 45g of polyethersulfone in 55g of diisobutyl phthalate to prepare a casting solution with a solid content of 45%;

[0083] Extrude the casting solution through a slit to obtain a liquid precursor film; pull the liquid precursor film through an air gap of 5 cm and then immerse it in ethanol for 3.5 hours to obtain a solid precursor film;

[0084] Then adopt 1 roller to wind up, obtain diaphragm semi-finished product, the ratio of the rotating speed of roller and extrusion speed is 1.1:1;

[0085] The solid precursor film was placed at 20°C for 4 hours; then at 45°C for 1 hour; finally at 65°C for 24 hours to obtain a porous separator. The Gurley value of the obtained porous membrane is 300sec·100mL -1 , the surface pore diameter is 0.07 μm, the internal pore diameter is 0.5 μm, and the porosity is 44%.

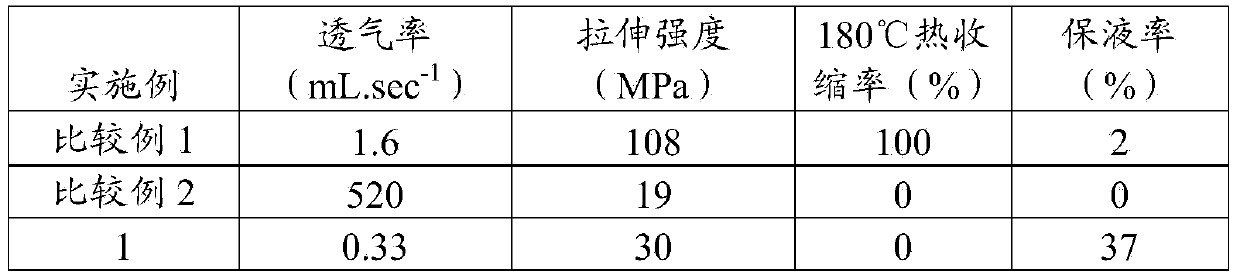

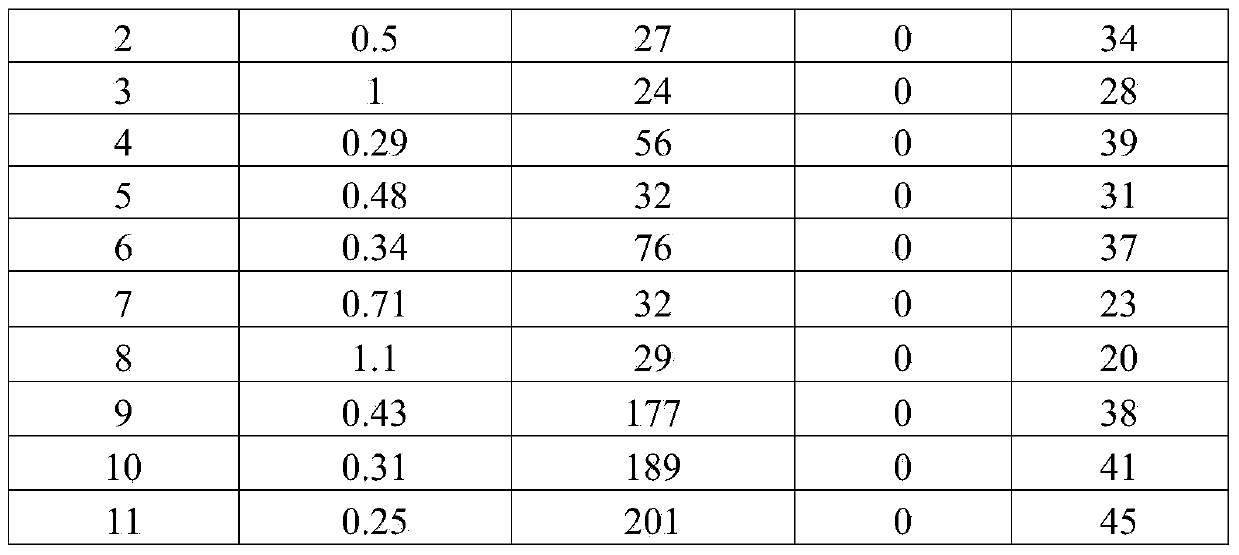

[0086] The present invention tests the air permeability of the porous diaphragm provided in this embodiment according to the above-mentioned technical solut...

Embodiment 2

[0092] 35g of polyacrylonitrile was dissolved in 65g of bis(2-ethylhexyl) phthalate to prepare a casting solution with a solid content of 35%;

[0093] Extruding the casting solution through a slit to obtain a liquid precursor film; pulling the liquid precursor film through an air gap of 25 cm and then immersing it in ethanol for 0.5 hours to obtain a solid precursor film;

[0094] Then adopt 1 roller to wind up, obtain diaphragm semi-finished product, the ratio of the rotating speed of roller and extrusion speed is 1.4:1;

[0095] The solid precursor film was placed at 30°C for 2 hours; then at 35°C for 4 hours; finally at 55°C for 15 hours to obtain a porous separator. The Gurley value of the obtained porous membrane is 200sec·100mL -1 , the surface pore diameter is 0.15 μm, the internal pore diameter is 1.5 μm, and the porosity is 62%.

[0096] The present invention tests the air permeability of the porous diaphragm provided in this embodiment according to the above-menti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gurley value | aaaaa | aaaaa |

| Surface aperture | aaaaa | aaaaa |

| Internal aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com