Preparation method of silicon/porous carbon nano-composite particle

A nano-composite, porous carbon technology, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of low lithium storage capacity of silicon-carbon composite materials, the cycle stability needs to be improved, and the cycle stability is not good enough, so as to achieve a good cycle Effects of stability, tight binding, and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

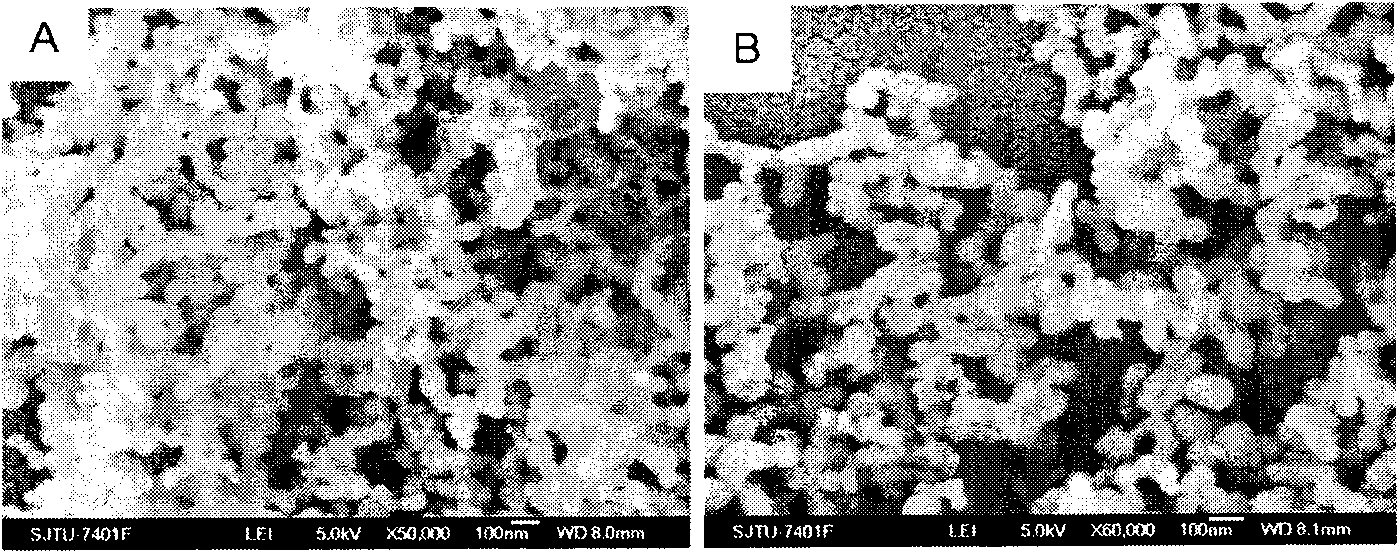

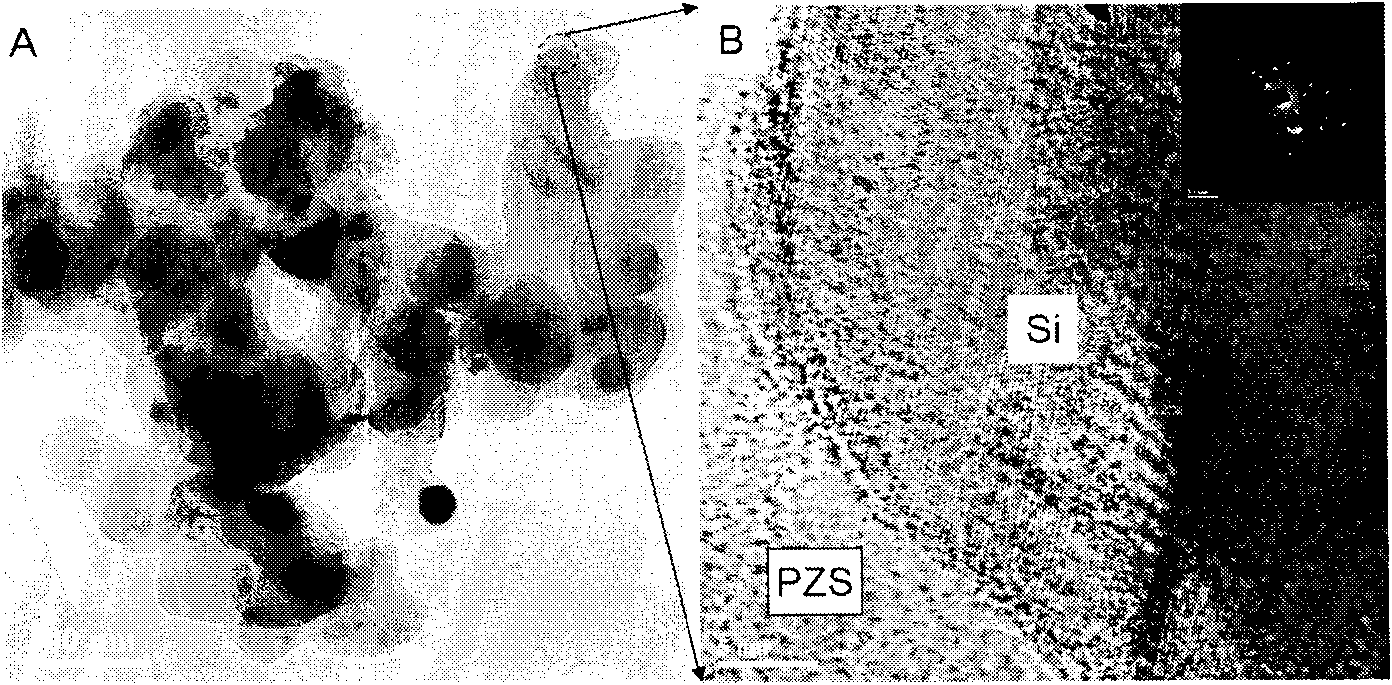

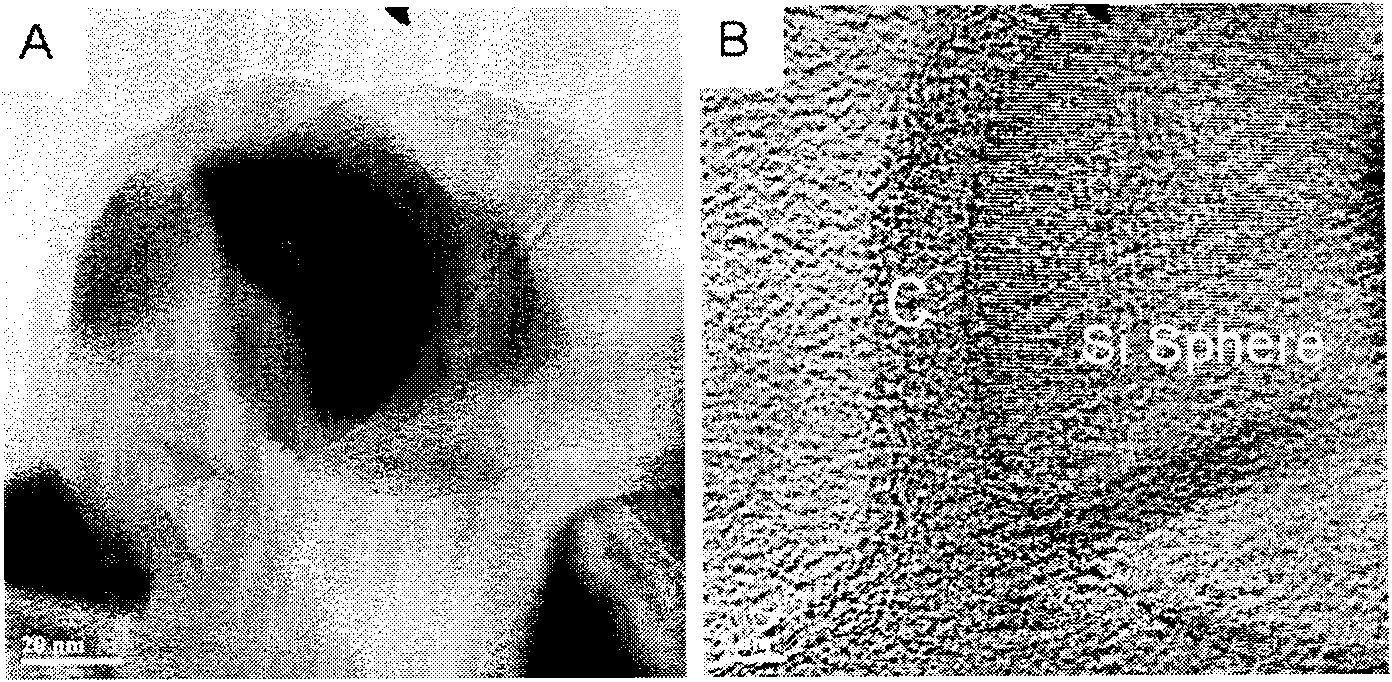

[0020] In a 100 ml flask, disperse 0.04 g of silicon spheres into 60 ml of tetrahydrofuran and ethanol mixed solvent, wherein the volume ratio of tetrahydrofuran to ethanol is 1:1, then add 0.04 g of hexachlorocyclotriphosphazene, 0.087 g of 4,4 '-Dihydroxydiphenyl sulfone and 0.5 mg of acid-binding agent triethylamine; ultrasonically react for 6-10 hours at 20-40°C, wherein the ultrasonic power is 100 watts, and the ultrasonic frequency is 40 kHz; Separate, wash with tetrahydrofuran, wash with deionized water, and dry in vacuum for 20 to 24 hours to obtain silicon / polyphosphazene nanocomposite microspheres with a core-shell structure; move the obtained silicon / polyphosphazene nanocomposite microspheres into In the quartz tube carbonization device, under the protection of high-purity nitrogen, the temperature was raised at a heating rate of 5°C / min, kept at 600°C for 2 hours, and then continued to rise to the predetermined temperature of the sample at a rate of 5°C / min at 900°C...

Embodiment 2

[0027] In a 100 ml flask, disperse 0.04 g of silicon spheres into 60 ml of tetrahydrofuran and ethanol mixed solvent, wherein the volume ratio of tetrahydrofuran to ethanol is 1:1, then add 0.04 g of hexachlorocyclotriphosphazene, 0.087 g of 4,4 '-Dihydroxydiphenyl sulfone and 0.5 mg of acid-binding agent triethylamine; ultrasonically react for 6-10 hours at 20-40°C, wherein the ultrasonic power is 100 watts, and the ultrasonic frequency is 40 kHz; Separate, wash with tetrahydrofuran, wash with deionized water, and dry in vacuum for 20 to 24 hours to obtain silicon / polyphosphazene nanocomposite microspheres with a core-shell structure; move the obtained silicon / polyphosphazene nanocomposite microspheres into In the quartz tube carbonization device, under the protection of high-purity nitrogen, the temperature was raised at a heating rate of 5°C / min, kept at 600°C for 2 hours, and then continued at a heating rate of 5°C / min to the predetermined sample temperature of 1000°C, and ...

Embodiment 3

[0029] In a 100 ml flask, disperse 0.04 g of silicon spheres into 60 ml of tetrahydrofuran and ethanol mixed solvent, wherein the volume ratio of tetrahydrofuran to ethanol is 1:1, then add 0.04 g of hexachlorocyclotriphosphazene, 0.087 g of 4,4 '-Dihydroxydiphenyl sulfone and 0.5 mg of acid-binding agent triethylamine; ultrasonically react for 6-10 hours at 20-40°C, wherein the ultrasonic power is 100 watts, and the ultrasonic frequency is 40 kHz; Separate, wash with tetrahydrofuran, wash with deionized water, and dry in vacuum for 20 to 24 hours to obtain silicon / polyphosphazene nanocomposite microspheres with a core-shell structure; move the obtained silicon / polyphosphazene nanocomposite microspheres into In the quartz tube carbonization device, under the protection of high-purity nitrogen, the temperature was raised at a heating rate of 5°C / min, kept at 600°C for 2 hours, and then continued to rise to the predetermined temperature of the sample at a rate of 5°C / min at 700°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com