Halogen-free inflaming retarding insulating material of nuclear cable and cable insulating layer as well as preparation method and application thereof

A technology of flame retardant insulating layer and insulating material, applied in the direction of insulated conductors, insulated cables, cables, etc., can solve the problems of poor radiation resistance, unsatisfactory halogen-free flame retardant properties, etc., and achieve stable radiation resistance and electrical properties. performance, suppressing damage, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Synthesis of polyphosphazene flame retardant hexaphenoxycyclotriphosphazene:

[0072] The specific operation process is:

[0073] 1), Preparation of phenol sodium salt: In a 20L glass reactor, under nitrogen protection, add 2kg phenol, 10L chlorobenzene, 200g polyethylene glycol, 45% sodium hydroxide solution, which contains 2.0mol of sodium hydroxide , the reaction temperature is 120-130°C, and the reaction time is 8-12 hours. After the reaction is completed, the water is separated by azeotropic distillation, and the reactant is cooled to room temperature for use.

[0074] 2), the preparation of hexaphenoxycyclotriphosphazene: in step 1) in the phenol sodium salt prepared, under nitrogen protection, add the 30% chlorobenzene solution that contains the hexachlorocyclotriphosphazene of commercially available 1.16kg, in React at 130-132°C for 6-12 hours, cool, filter, distill the filtrate under reduced pressure, recover the solvent chlorobenzene, add hot ethanol to the r...

Embodiment 2

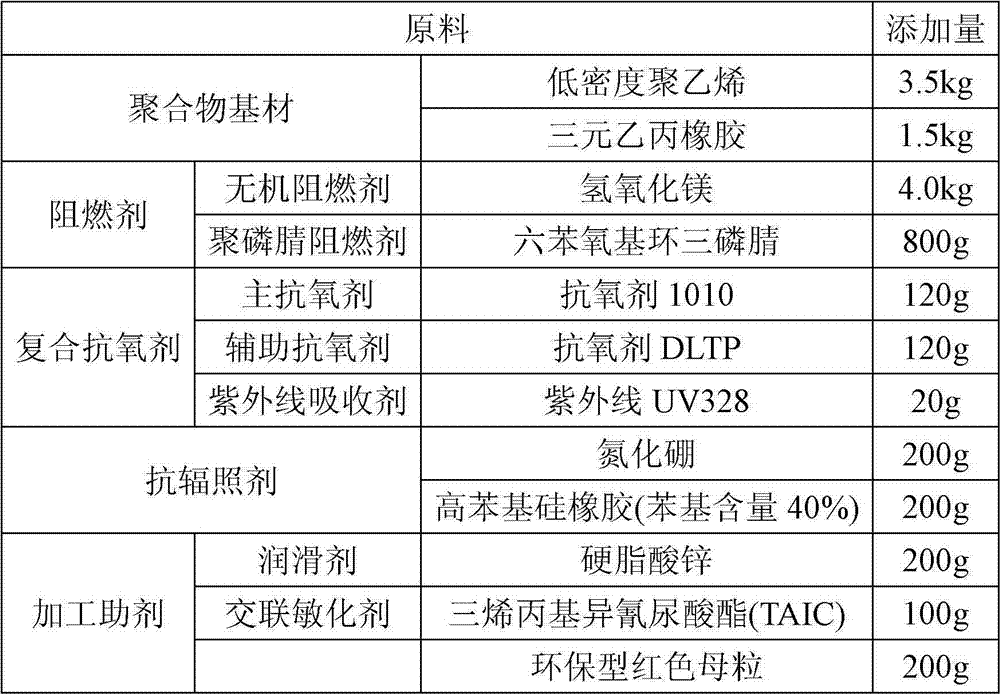

[0076] raw material:

[0077]

[0078] Wherein, the polyphosphazene flame retardant used is the hexaphenoxycyclotriphosphazene prepared in Example 1.

[0079] Steps:

[0080] Put low-density polyethylene, EPDM rubber, antioxidant 1010, antioxidant DLTP, ultraviolet UV328, boron nitride, magnesium hydroxide, hexaphenoxycyclotriphosphazene and environmentally friendly red masterbatch into 10 In the internal mixer, add high phenyl silicone rubber, zinc stearate, triallyl isocyanurate (TAIC) and mix for 10 minutes when the internal mixer reaches 145°C, turn over the internal mixer, and pour the material into hoist up to Single-screw extruder, extruded and granulated at 120-160°C, air-cooled to obtain halogen-free flame-retardant insulating material.

Embodiment 3

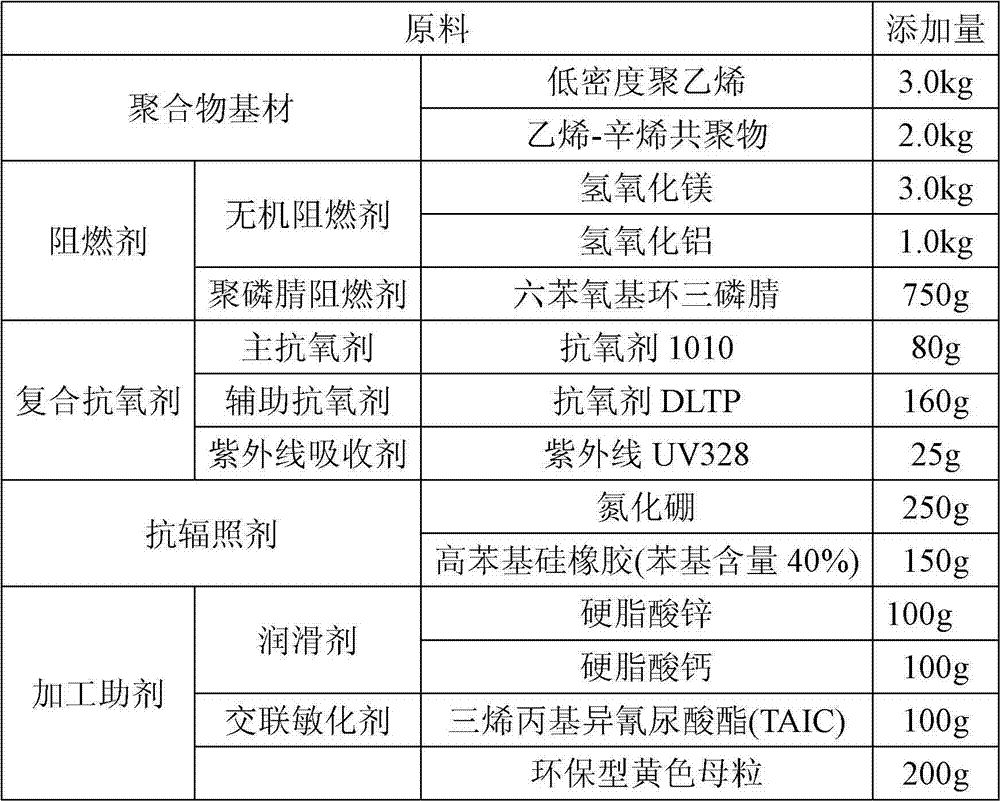

[0082] raw material:

[0083]

[0084] Wherein, the polyphosphazene flame retardant used is the hexaphenoxycyclotriphosphazene prepared in Example 1.

[0085] Steps:

[0086] Low-density polyethylene, ethylene-octene copolymer, antioxidant 1010, antioxidant DLTP, ultraviolet UV328, boron nitride, magnesium hydroxide, aluminum hydroxide, hexaphenoxycyclotriphosphazene and environmentally friendly yellow Put the masterbatch into a 10-liter internal mixer, add high-phenyl silicone rubber, zinc stearate, calcium stearate, triallyl isocyanurate (TAIC) and mix for 10 minutes when the internal mixer reaches 145°C , turn over the internal mixer, pour the material into the elevator and lift it to Single-screw extruder, extruded and granulated at 120-160°C, air-cooled to obtain halogen-free flame-retardant insulating material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com