Halogen-free flame retardant sheath material for nuclear cable, cable sheath, preparation method and application

A flame retardant sheath, inorganic flame retardant technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of unsatisfactory halogen-free flame retardant performance, thermal aging of cable sheath materials, poor mechanical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Synthesis of polyphosphazene flame retardant hexaphenoxycyclotriphosphazene:

[0074] The specific operation process is:

[0075] 1), the preparation of phenol sodium salt: in the stainless steel reactor of 100L, add the sodium hydroxide solution of 10Kg phenol, 50L chlorobenzene, 1Kg Polyethylene Glycol, 45% under nitrogen protection, wherein contain the sodium hydroxide of 10mol, The reaction temperature is 120-130° C., and the reaction time is 8-12 hours. After the reaction is completed, azeotropic distillation is carried out to separate water, and the reactant is cooled to room temperature for use.

[0076] 2), the preparation of hexaphenoxycyclotriphosphazene: in step 1) in the phenol sodium salt of preparation, add the 30% chlorobenzene solution that contains the hexachlorocyclotriphosphazene of commercially available 5.8Kg under nitrogen protection, in React at 130-132°C for 6-12 hours, cool, filter, distill the filtrate under reduced pressure, recover the solve...

Embodiment 2

[0078] raw material:

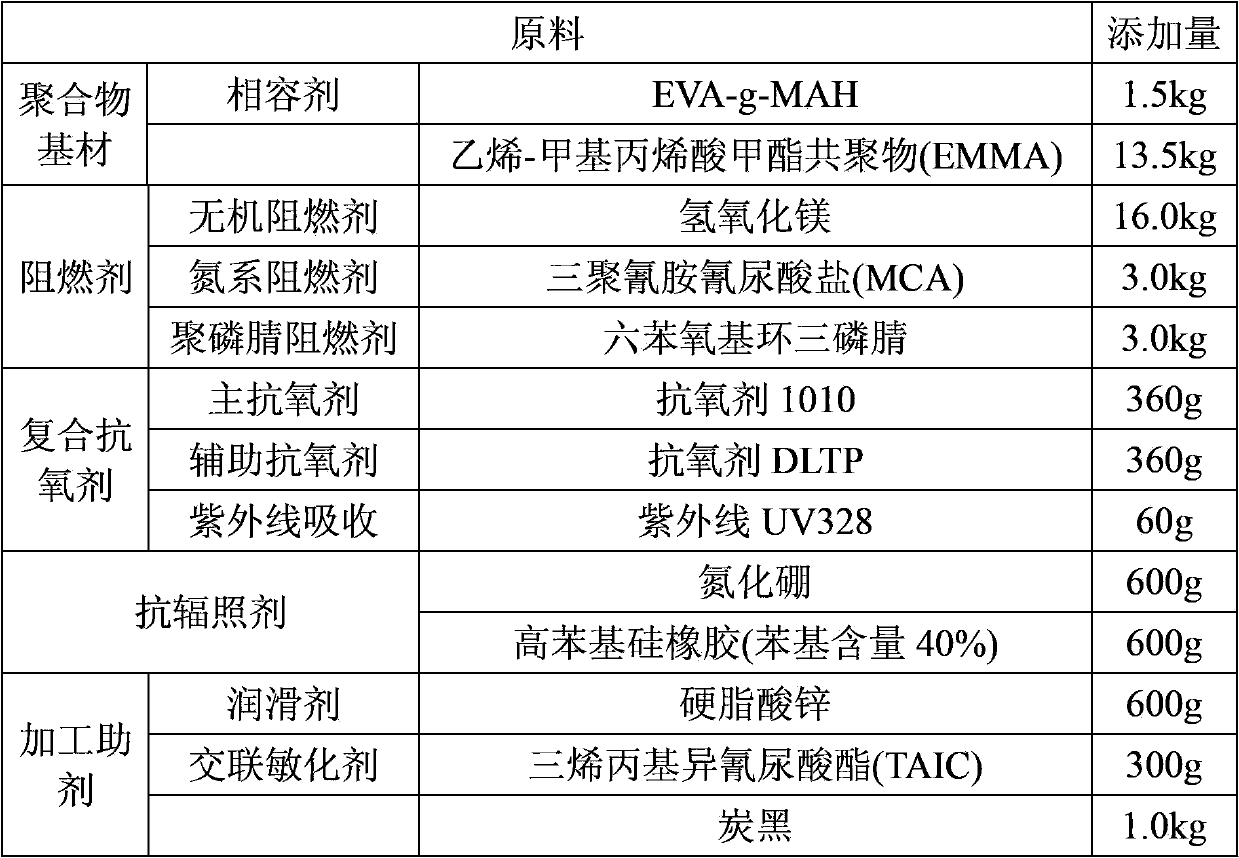

[0079]

[0080] Wherein, the polyphosphazene flame retardant used is the hexaphenoxycyclotriphosphazene prepared in Example 1.

[0081] Steps:

[0082] The compatibilizer EVA-g-MAH, ethylene-methyl methacrylate copolymer (EMMA, antioxidant 1010, antioxidant DLTP, ultraviolet UV328, boron nitride, magnesium hydroxide, melamine cyanurate (MCA ), hexaphenoxycyclotriphosphazene and carbon black were put into a 35-liter internal mixer, and when banburying to 130°C, high-phenyl silicone rubber (40% phenyl content, zinc stearate, triallyl Based on isocyanurate (TAIC), after mixing for 10 minutes (mixing temperature 120-140°C), turn over the internal mixer, pour the material into the elevator and raise it to A twin-screw extruder is used to extrude and granulate at 110-150°C, and air-cooled to obtain nuclear power K1 halogen-free flame-retardant sheathing material.

Embodiment 3

[0084] raw material:

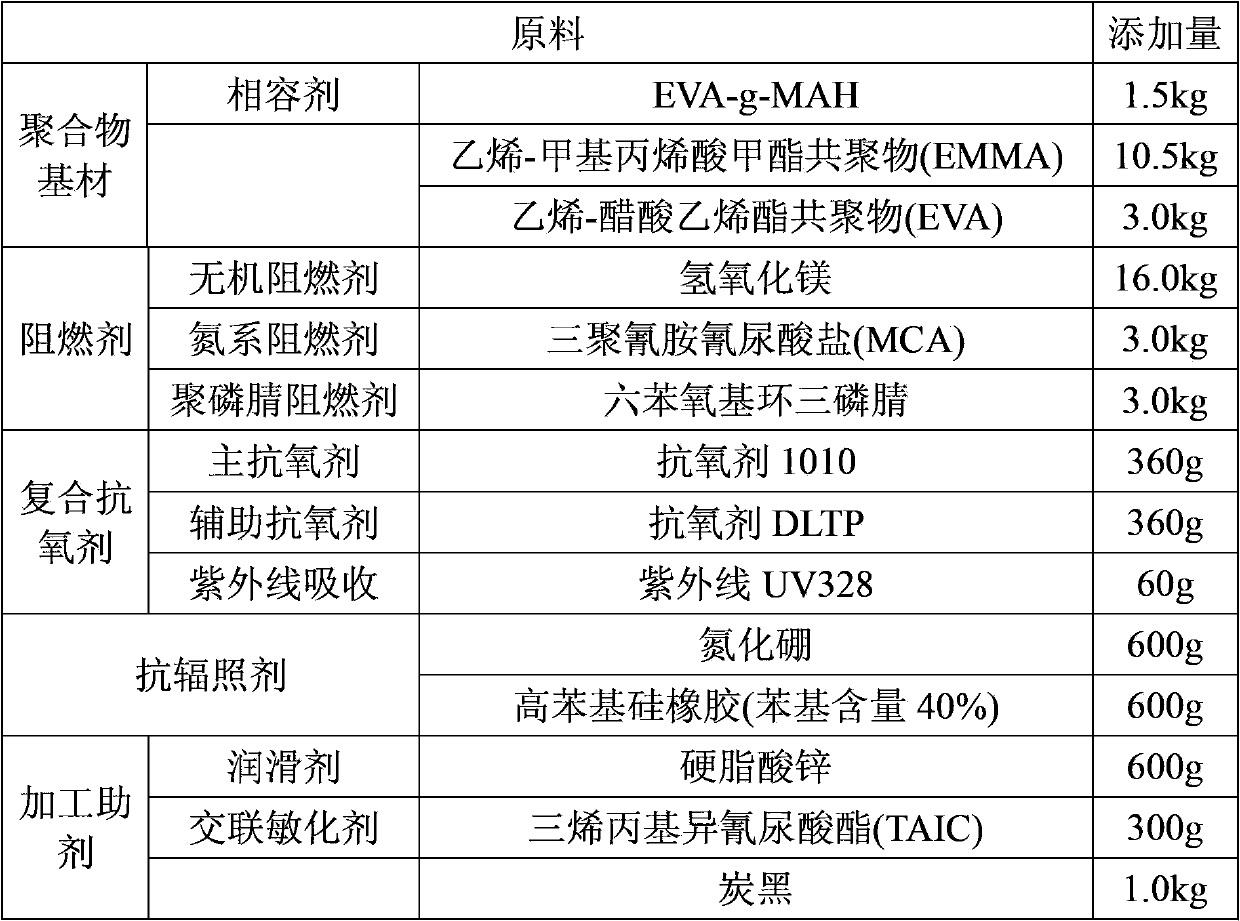

[0085]

[0086] Wherein, the polyphosphazene flame retardant used is the hexaphenoxycyclotriphosphazene prepared in Example 1.

[0087] Steps:

[0088] The compatibilizer EVA-g-MAH, ethylene-methyl methacrylate copolymer (EMMA), ethylene-vinyl acetate copolymer (EVA), antioxidant 1010, antioxidant DLTP, ultraviolet UV328, boron nitride , magnesium hydroxide, melamine cyanurate (MCA), hexaphenoxycyclotriphosphazene and carbon black were put into a 35-liter internal mixer, and when it was mixed to 130°C, high-phenyl silicone rubber (phenyl Content 40%, zinc stearate, triallyl isocyanurate (TAIC), after mixing for 10 minutes (mixing temperature 120-140 ℃), turn over the internal mixer, pour the material into the elevator and raise it to A twin-screw extruder is used to extrude and granulate at 110-150°C, and air-cooled to obtain nuclear power K1 halogen-free flame-retardant sheathing material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com