Method for preparing 5-hydroxymethylfurfural

A kind of hydroxymethyl furfural, a single technology, applied in the field of preparing 5-hydroxymethyl furfural (HMF), can solve problems such as instability of ion exchange resin, achieve good thermal stability and acid stability, avoid corrosion and environmental pollution , The effect of preparation process environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

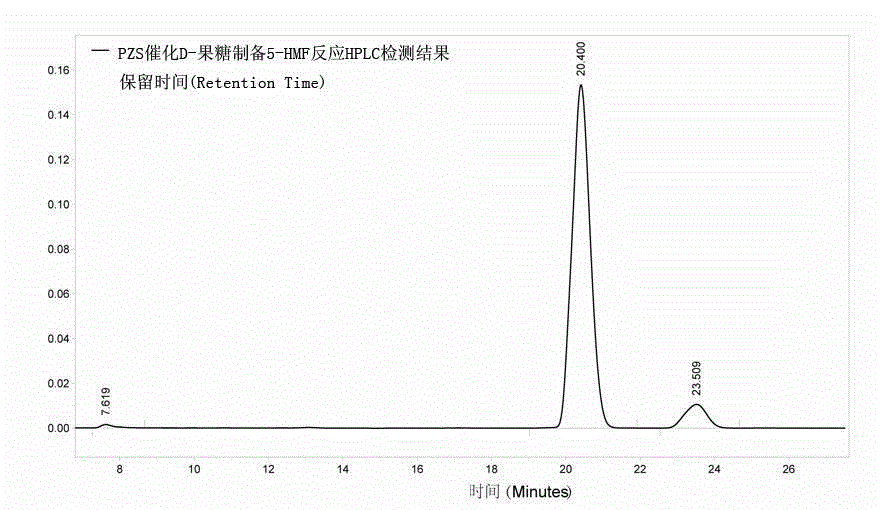

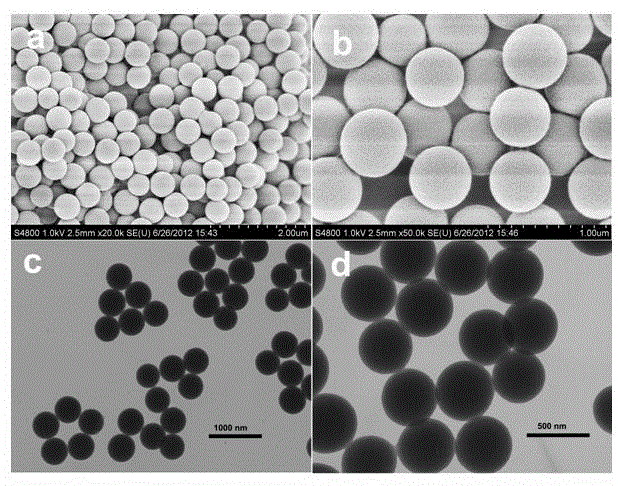

[0030] Embodiment 1: the preparation of catalyst PZS microsphere

[0031] Dissolve 0.2 g of hexachlorotripolyphosphazene and 0.43 g of bisphenol S in 50 mL of acetone, sonicate at 200 W for 10 min to make the raw materials evenly dissolve in the solvent, then add 1.82 g of trioctylamine, continuously sonicate at room temperature for 2 h, and then The solvent was removed by centrifugation at a rate of 6000 rpm to obtain solid particles, which were washed 3 times with acetone, ethanol and deionized water repeatedly, 45 o C dried in a vacuum oven for 24 h to obtain a solid PZS polymer microsphere catalyst.

Embodiment 2

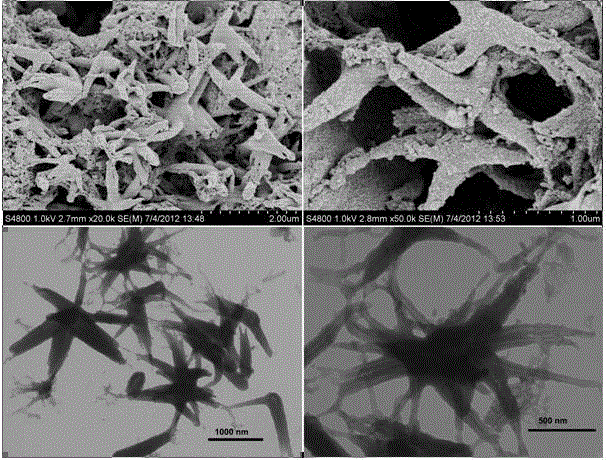

[0032] Embodiment 2: preparation of catalyst PZS nanotube (nanotube, NT)

[0033] Dissolve 0.2 g of hexachlorotripolyphosphazene and 0.50 g of bisphenol S in 50 mL of tetrahydrofuran, ultrasonicate at 200 W for 15 min to make the raw materials evenly dissolve in the solvent, then add 0.52 g of triethylamine, 35 o C was continuously sonicated for 3 h, and then centrifuged at 8000 rpm to remove the solvent to obtain solid particles, which were washed 3 times with acetone, ethanol and deionized water repeatedly, 45 o C dried in a vacuum oven for 24 h to obtain a solid PZS polymer nanotube (PZS NT) catalyst.

Embodiment 3

[0034] Embodiment 3: the preparation of catalyst PZAF microsphere

[0035] Dissolve 0.2 g of hexachlorotripolyphosphazene and 0.68 g of bisphenol AF in 50 mL of acetonitrile, ultrasonicate at 200 W for 10 min to make the raw materials evenly dissolve in the solvent, then add 0.95 g of tributylamine, 40 o C was continuously sonicated for 8 h, and then centrifuged at 8000 rpm to remove the solvent to obtain solid particles, which were washed 3 times with acetone, ethanol and deionized water, 45 o C dried in a vacuum oven for 24 h to obtain a solid PZAF polymer catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com