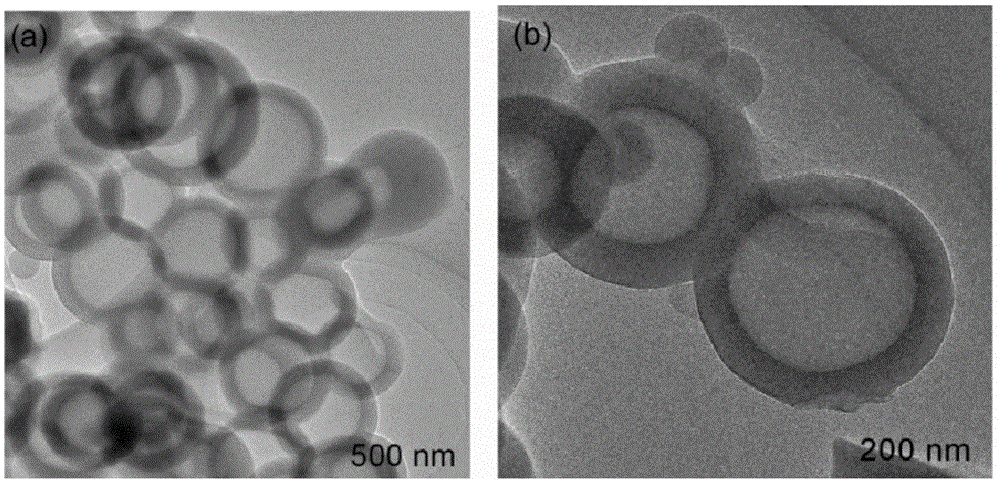

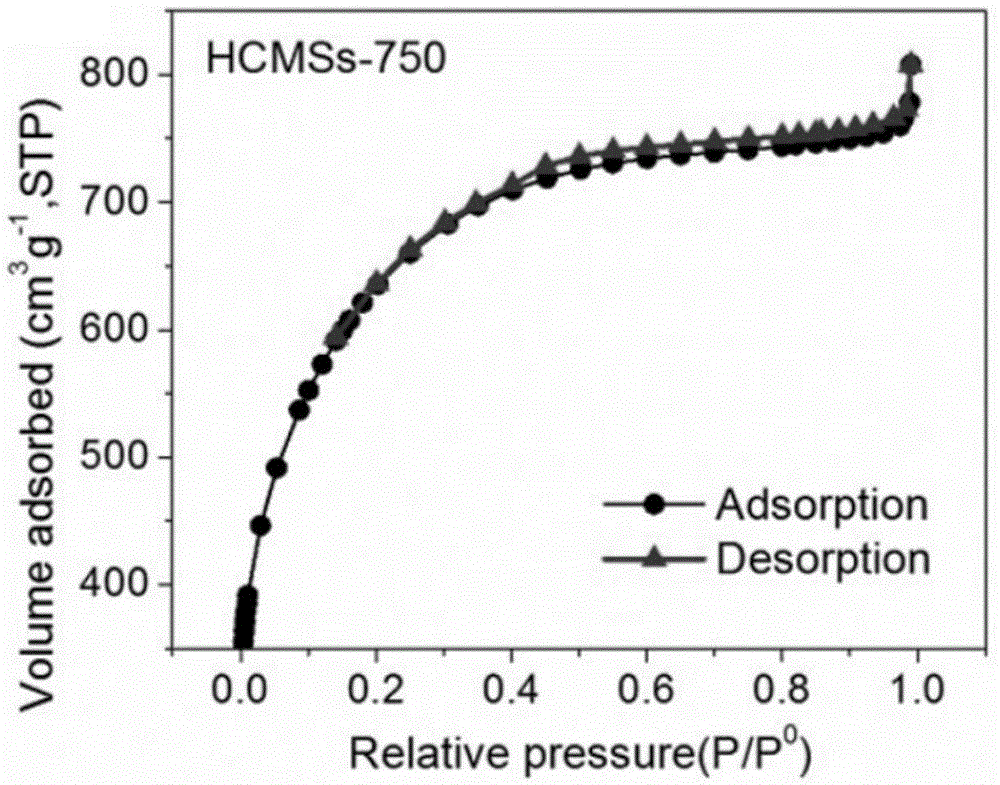

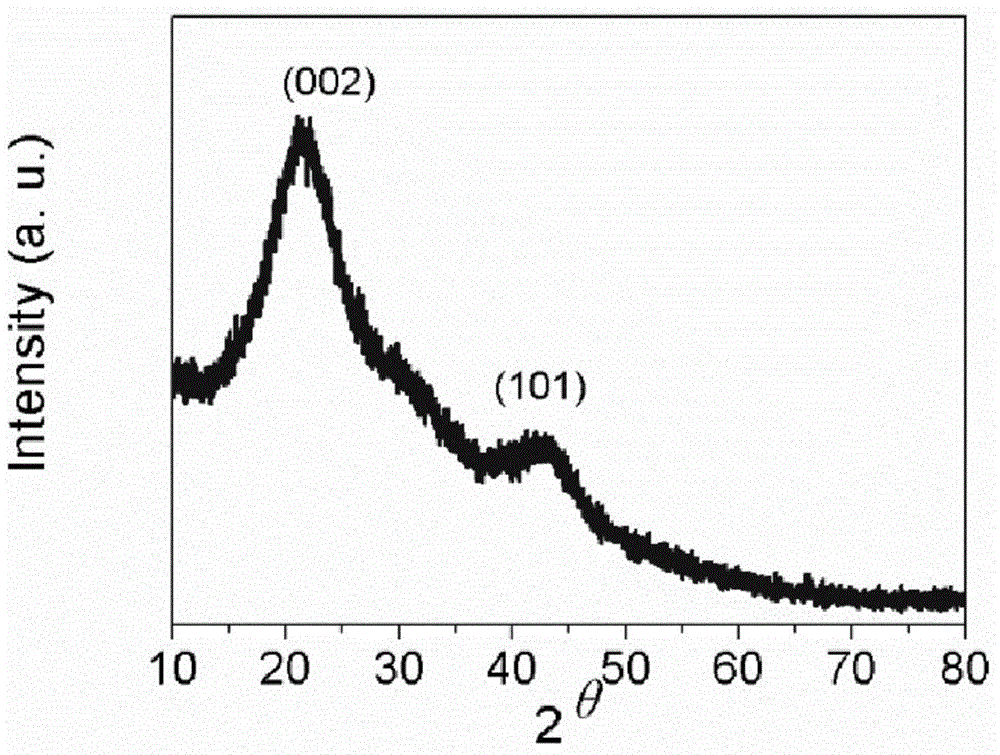

Heteroatom doped hollow porous carbon microspheres and preparation method thereof

A hollow microsphere and porous carbon technology, applied in the field of inorganic carbon nanometers, can solve the problems of uneven pore size distribution of hollow microspheres, negative impact on material properties, difficult structure, etc., and achieve high yield, uniform material structure, and large specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment includes the following steps:

[0036] 1) In a dry 150mL single-necked flask, dissolve 1.0g of 4,4'-thiobisthiophenol in 60mL of acetonitrile and disperse evenly by ultrasonication. Add 1mL of triethylamine to the above reaction solution and continue the reaction for 30 minutes. This reaction liquid is added in the polytetrafluoroethylene digestion tank that contains 0.5g hexachlorocyclotriphosphazene and 0.5g p-phenylenediamine, in the system, add appropriate amount of triethylamine as acid-binding agent, then the digestion tank is sealed, 160 ℃ for 3 hours. After the reaction, the product was filtered, washed with water and ethanol to obtain polyphosphazene hollow microspheres.

[0037] 2) Put the polyphosphazene microspheres into a porcelain boat, place it in the middle of the furnace cavity of the tube furnace, seal the tube furnace, and pass inert gas for 1 hour to replace the oxygen in the furnace cavity.

[0038] In this embodiment, the heating ...

Embodiment 2

[0043] This embodiment includes the following steps:

[0044] 1) In a 150mL dry single-necked flask, dissolve 1.0g of 4,4'-thiobisthiophenol in 60mL of acetonitrile and disperse evenly by ultrasonication. Add 0.5mL of triethylamine to the above reaction solution and continue the reaction for 30 minutes. Add the reaction solution into a polytetrafluoroethylene digestion tank containing 0.5g hexachlorocyclotriphosphazene and 1.0g4,4'-diaminodiphenylmethane, add an appropriate amount of triethylamine as an acid-binding agent in the system, and then The digestion tank was sealed and reacted at 160°C for 3 hours. After the reaction, the product was filtered, washed with water, and washed with ethanol to obtain polyphosphazene hollow microspheres

[0045] 2) Put the polyphosphazene microspheres into a porcelain boat, place it in the middle of the furnace cavity of the tube furnace, seal the tube furnace, and pass inert gas for 1 hour to replace the oxygen in the furnace cavity.

...

Embodiment 3

[0050] This embodiment includes the following steps:

[0051] 1) In a dry 150mL single-necked flask, dissolve 1.0g of 4,4'-thiobisthiophenol in 60mL of acetonitrile, disperse evenly by ultrasonic (150W, 50°C), add 1mL of triethylamine to the above reaction solution, continue React for 30 minutes. Add the reaction liquid into a flask containing 0.5g of hexachlorocyclotriphosphazene and 1.1g of 4,4'-dihydroxydiphenyl sulfone, and disperse it evenly by ultrasonication. Add an appropriate amount of triethylamine to the system as an acid-binding agent. React for 3 hours. After the reaction, the product was filtered, washed with water, and washed with ethanol to obtain polyphosphazene hollow microspheres

[0052] 2) Put the polyphosphazene microspheres into the porcelain boat, and place it in the middle of the cavity of the tube furnace.

[0053] In this embodiment, the heating setting of the tube furnace is as follows: the temperature is raised from normal temperature to 350°C a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com