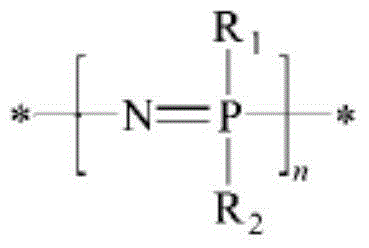

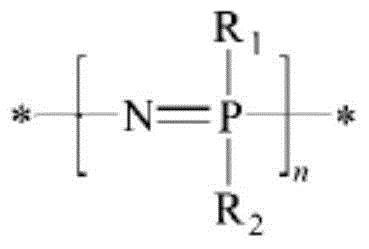

Preparation method of self-crosslinked phosphazene elastomer

A self-crosslinking and elastomer technology, applied in the field of polyphosphazene, can solve the problems affecting the thermal stability of cross-linked phosphazene elastomer products, cross-linked polyphosphazene elastomers, and cross-linking conditions by adding cross-linking agents, etc. The problem is that the preparation method and the cross-linking method are simple, the difficulty of cross-linking and the cost of cross-linking are reduced, and the cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Under the protection of nitrogen, add ethylene glycol to the flask connected with the condenser tube, the substance ratio of alcohol to sodium hydride is 1.5:1, and the solvent tetrahydrofuran, and add sodium hydride to the flask at room temperature until the sodium hydride is completely The reaction obtains ethylene glycol monosodium salt solution; under nitrogen protection, add n-butanol to a flask connected with a condenser, the mol ratio of alcohol to sodium hydride is 1.5:1, and solvent tetrahydrofuran, at room temperature the sodium hydride Add in the flask until sodium hydride reacts completely to obtain sodium n-butoxide solution; under nitrogen protection, add phenol to the flask connected with the condenser tube, the molar ratio of phenol to sodium hydride is 1.5:1, and solvent tetrahydrofuran, at room temperature Next, add sodium hydride into the flask until the sodium hydride reacts completely to obtain a sodium phenoxide solution; take a tetrahydrofuran solu...

Embodiment 2

[0025] Under the protection of nitrogen, add ethylene glycol to the flask connected with the condenser tube, the substance ratio of alcohol to sodium hydride is 1.5:1, and the solvent tetrahydrofuran, and add sodium hydride to the flask at room temperature until the sodium hydride is completely The reaction obtains ethylene glycol monosodium salt solution; under nitrogen protection, add n-butanol to a flask connected with a condenser, the mol ratio of alcohol to sodium hydride is 1.5:1, and solvent tetrahydrofuran, at room temperature the sodium hydride Add in the flask until sodium hydride reacts completely to obtain sodium n-butoxide solution; under nitrogen protection, add phenol to the flask connected with the condenser tube, the molar ratio of phenol to sodium hydride is 1.5:1, and solvent tetrahydrofuran, at room temperature Next, add sodium hydride into the flask until the sodium hydride reacts completely to obtain a sodium phenoxide solution; take a tetrahydrofuran solu...

Embodiment 3

[0027] Under the protection of nitrogen, add ethylene glycol to the flask connected with the condenser tube, the substance ratio of alcohol to sodium hydride is 1.5:1, and the solvent tetrahydrofuran, and add sodium hydride to the flask at room temperature until the sodium hydride is completely The reaction obtains ethylene glycol monosodium salt solution; under the protection of nitrogen, add trifluoroethanol to the flask connected with the condenser, the mol ratio of alcohol to sodium hydride is 1.5:1, and solvent tetrahydrofuran, at room temperature the sodium hydride Add in the flask until sodium hydride reacts completely to obtain sodium trifluoroethoxide solution; under nitrogen protection, add phenol to the flask connected with the condenser tube, the molar ratio of phenol to sodium hydride is 1.5:1, and solvent tetrahydrofuran, at room temperature Next, add sodium hydride into the flask until the sodium hydride reacts completely to obtain a sodium phenoxide solution; ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com