Flame-retardant resin composition, and insulated electric wire, flat cable, and molded article, which are made using same

A resin composition, flame retardant technology, applied in the direction of insulated cables, flat/ribbon cables, plastic/resin/wax insulators, etc., can solve problems such as dyeing of insulating layers, and achieve the effect of high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

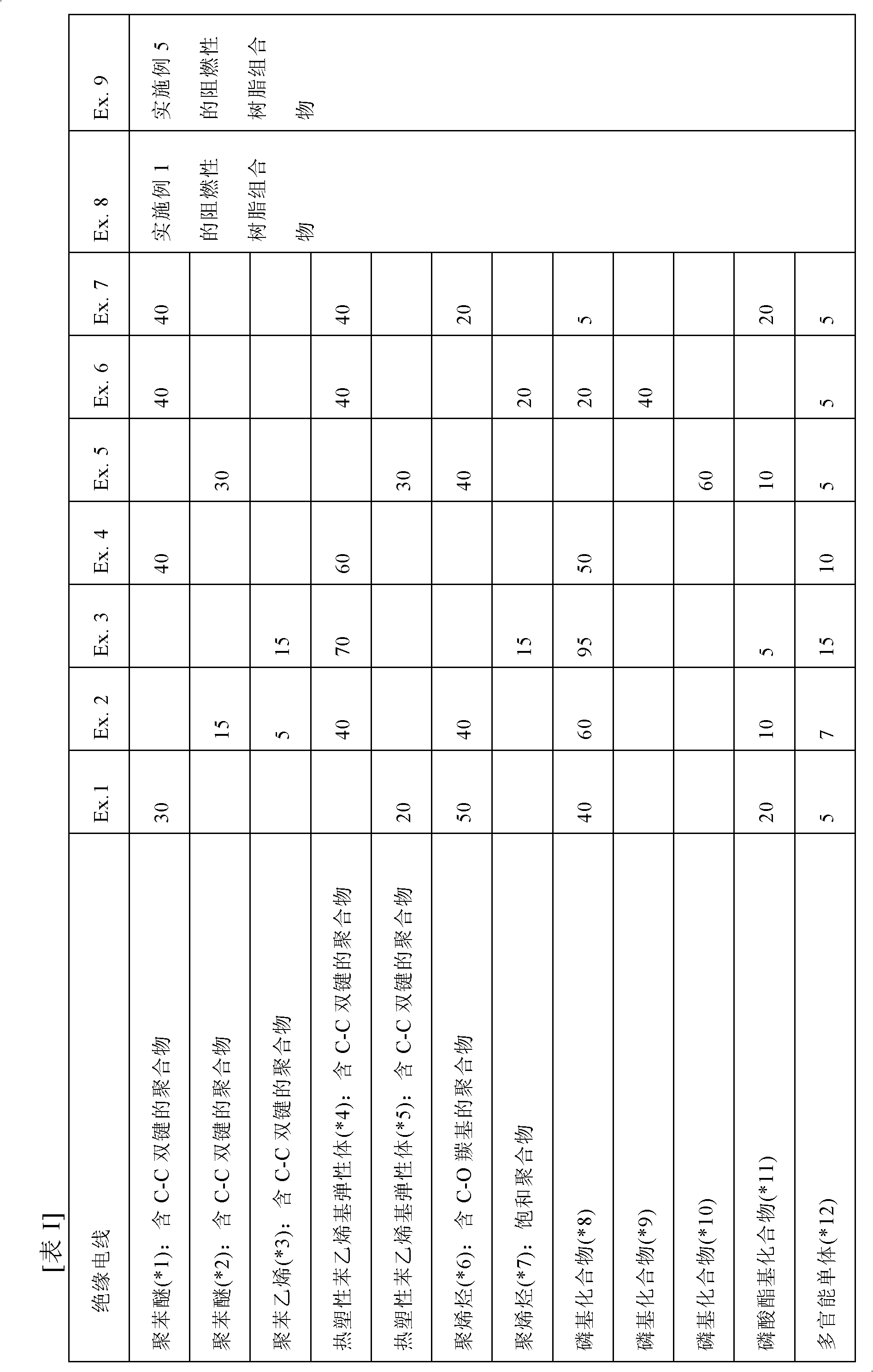

[0062] Next, the present invention will be described in further detail by using examples. The following examples do not limit the scope of the invention. It should be noted that "parts" in the tables mean "parts by mass" unless otherwise specified.

[0063] First, the measurement and evaluation methods performed in the following examples will be described.

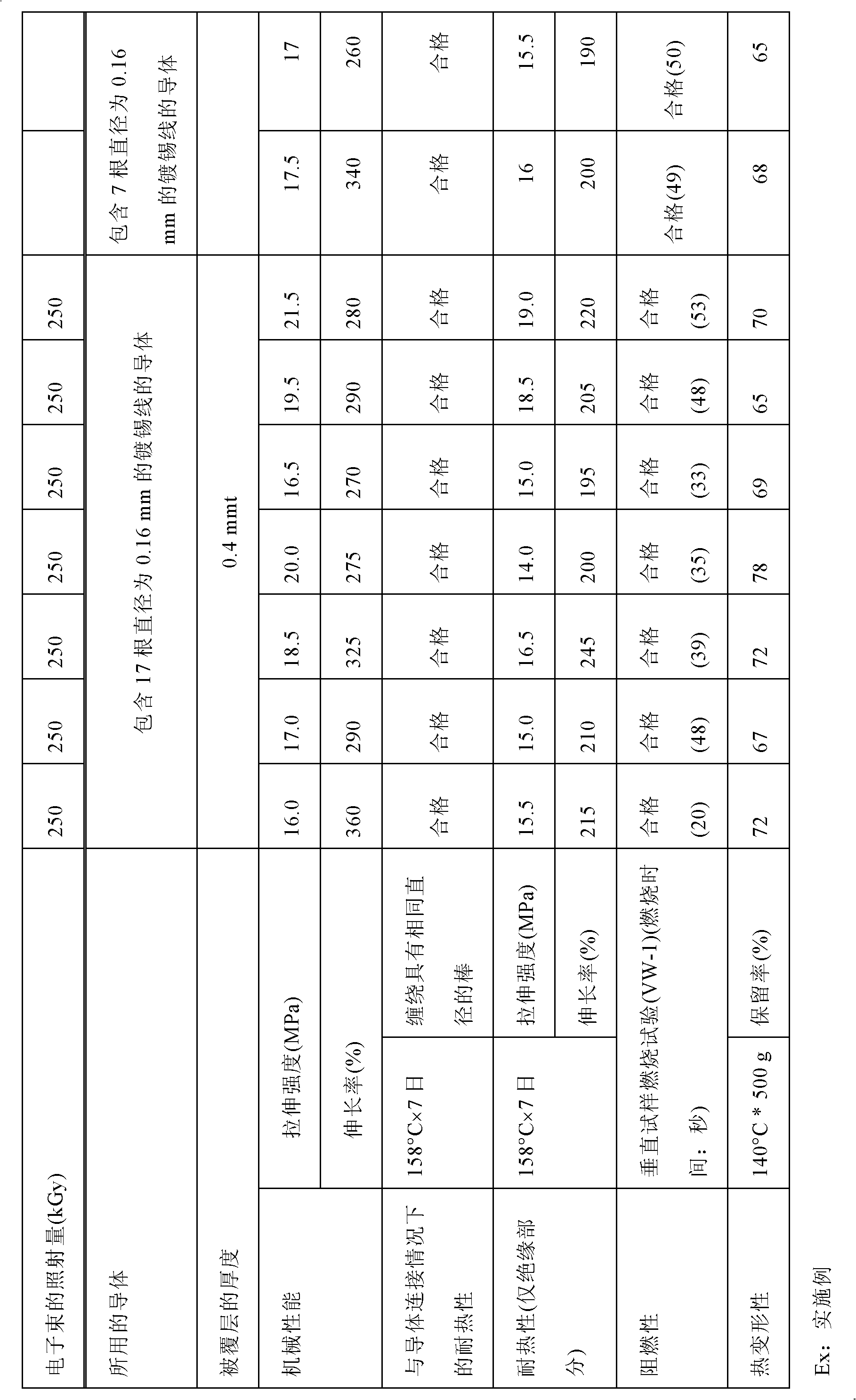

[0064] (Mechanical behavior)

[0065] Tensile tests were performed on the covering layers of insulated wires and flat cables (tensile speed = 500 mm / min, distance between marked lines = 20 mm). Three samples were used to measure tensile strength (MPa) and elongation at break (%), and their average values were calculated. A tensile strength of 10.4 MPa or more and an elongation at break of 150% are set as acceptable levels.

[0066] (heat resistance)

[0067] The insulated wires and flat cables were placed in a Geer oven set at 158° C. for 168 hours (7 days), and then subjected to the same tensile test as that used t...

Embodiment 1 to 19 and comparative example 1 to 10

[0075] The materials were blended in the proportions shown in Tables I to III. To each of the obtained mixtures, 0.5 parts of oleic acid amide and 3 parts of tetrakis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid] were added to 100 parts of the base polymer pentaerythritol ester, and the resulting mixture was kneaded using a twin-screw extruder with a die set at a temperature of 280°C. The obtained kneaded strands were pelletized with a pelletizer, and extruded using a melt extruder (diameter 45 mm, L / D ratio = 24, compression ratio: 2.5, full screw type) to coat the conductor (the prepared by twisting 17 tinned annealed copper wires with a diameter of 0.16 mm) so that the thickness of the coating layer on the conductor was 0.4 mm. Subsequently, an electron beam of 250 kGy was applied at an accelerating voltage of 2 MeV to form an insulated wire. In Examples 8 and 9, a conductor prepared by twisting 7 tinned annealed copper wires having a diameter of 0.16 mm was used, ...

Embodiment 20 to 22 and comparative example 11 to 18

[0077] The flame retardant resin compositions shown in Tables IV and V were used. Eight conductors (flat rectangular conductors with a thickness of 0.15 mm and a width of 1.2 mm) were arranged side by side at a pitch of 0.8 mm (pitch: 2.0 mm), and each flame-retardant resin composition was extruded to coat both sides of the conductors , so that the thickness of the covering layer is 0.2 mm. Subsequently, an electron beam of 250 kGy was applied at an acceleration voltage of 2 MeV to form a flat cable. Subsequently, a series of evaluations are performed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com