Environmentally-friendly halogen-free reaction type soft and hard segment co-modified flame retardant waterborne polyurethane fabric coating agent and preparation method thereof

A water-based polyurethane, reactive technology, applied in the direction of fiber type, textile and papermaking, fiber processing, etc., can solve the problem of large amount of smoke, and achieve the effect of smaller fabric color, no influence on hand feeling, and remarkable flame retardant effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

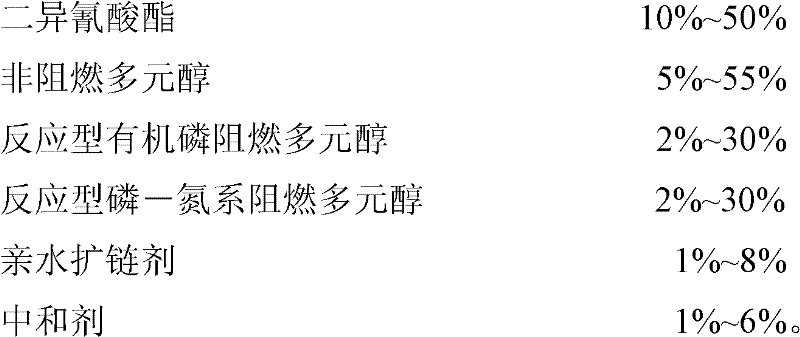

[0026] The formula of the environmentally friendly halogen-free reactive soft and hard segment co-modified flame-retardant waterborne polyurethane fabric coating agent is shown in Table 1:

[0027] Table 1 Example 1 Formula of environmentally friendly halogen-free reactive soft and hard segment co-modified solar-burning waterborne polyurethane fabric coating agent

[0028] raw material

Mass / g

Isophorone diisocyanate

65

Polyether polyol (hydroxyl value 110mgKOH / g)

110

Organic phosphorus flame retardant polyol (hydroxyl value 100mgKOH / g)

12

Phosphorus-nitrogen flame retardant polyol (hydroxyl value 435mgKOH / g)

8

6

8.2

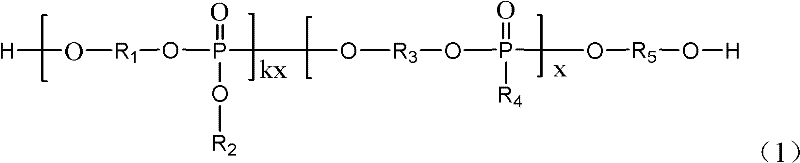

[0029] The structural formula of organophosphorus polyol is:

[0030] H-[-OCH 2 OP(O)(OCH 3 )] 2x -[-OCH 2 OP(O)(CH 3 )] x -OCH 2 -OH

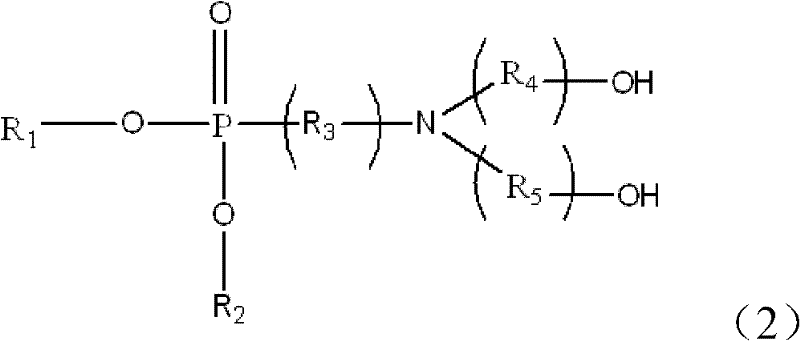

[0031] The reactive phosphorus-nitrogen flame-retardant polyol is: N-hydroxymethyl, N-hydroxyethylaminoethyl phosphonic acid dimethyl ester.

[0032] 1) In a four-necked flask ...

Embodiment 2

[0037] The formula of the environmentally friendly halogen-free reactive soft and hard segment co-modified flame-retardant waterborne polyurethane fabric coating agent is shown in Table 2:

[0038] Table 2 Example 2 Formula of environmentally friendly halogen-free reactive soft and hard segment co-modified solar-burning waterborne polyurethane fabric coating agent

[0039] raw material

Mass / g

2,6-Diisocyanate methyl caproate

63

Polyester polyol (hydroxyl value 105mgKOH / g)

100

Organophosphorus polyol (hydroxyl value 135mgKOH / g)

15.7

Phosphorus-nitrogen flame-retardant polyol (hydroxyl value 450mgKOH / g)

8

Dihydroxy half ester

14

3.4

[0040] The structural formula of organophosphorus polyol is:

[0041] H-[-OCH 2 CH 2 OP(O)(OCH 3 )] 2x -[-OCH 2 OP(O)(CH 2 CH 3 )] x -OCH 2 -OH

[0042] The reactive phosphorus-nitrogen flame-retardant polyol is: N-hydroxymethyl, N-hydroxypropylaminomethylphosphonic acid diethyl ester.

[0043] 1) In a four-necked flask ...

Embodiment 3

[0048] The formula of the environmentally friendly halogen-free reactive soft and hard segment co-modified flame-retardant waterborne polyurethane fabric coating agent is shown in Table 3:

[0049] Table 3 Example 3 Formula of environmentally friendly halogen-free reactive soft and hard segment co-modified flame-retardant waterborne polyurethane fabric coating agent

[0050] raw material

Mass / g

50

Polyester polyol (hydroxyl value 100mgKOH / g)

90

Organophosphorus polyol (hydroxyl value 110mgKOH / g)

30.2

Phosphorus-nitrogen flame-retardant polyol (hydroxyl value 410mgKOH / g)

40

12

9.6

[0051] The structural formula of organophosphorus polyol is:

[0052] H-[-OCH 2 CH 2 OP(O)(OCH 3 )] x -[-OCH 2 OP(O)(CH 3 )] x -OCH 2 CH 2 -OH

[0053] The reactive phosphorus-nitrogen flame retardant polyol is: dimethyl bis(hydroxymethyl)aminoethylphosphonate

[0054] 1) In a four-necked flask equipped with a stirrer, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Damage length | aaaaa | aaaaa |

| Damage length | aaaaa | aaaaa |

| Damage length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com