Reactive polyurethane hot melt adhesive and preparation method thereof

A polyurethane hot melt adhesive, reactive technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problem of increased PUR melt viscosity, poor PUR bonding performance, and poor PUR flame retardant performance. and other problems, to achieve excellent flame retardancy and adhesion, improve initial adhesion, and good environmental resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

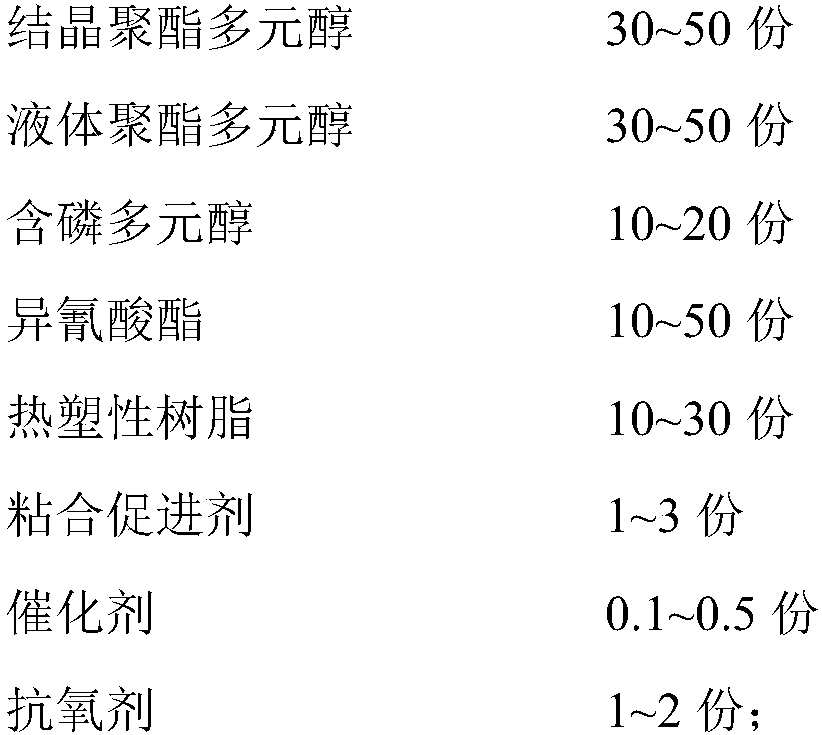

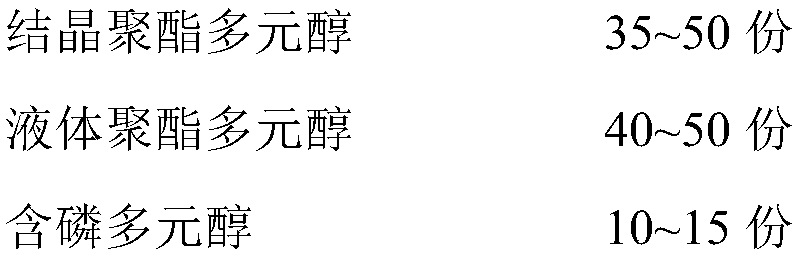

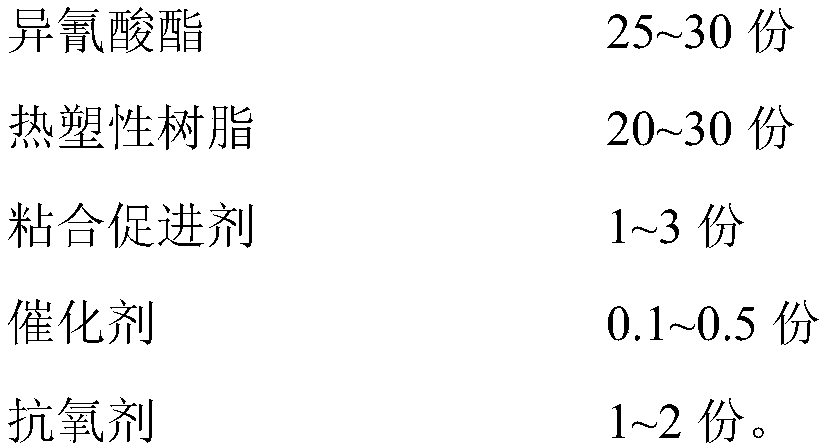

[0056]Three kinds of reactive polyurethane hot-melt adhesives of the present embodiment, in parts by weight, the raw material components are as follows (Table 1):

[0057] Table 1

[0058]

[0059]

[0060] The preparation method of above-mentioned reactive polyurethane hot-melt adhesive is as follows:

[0061] (1), put crystalline polyester polyol, liquid polyester polyol, phosphorus-containing polyol, thermoplastic resin into the reaction kettle, heat to 100~130 ℃, vacuum dehydration under stirring for 2 hours, the vacuum degree is -0.095~ 0.05MPa;

[0062] (2) Cool down to 80-90°C, put in the isocyanate preheated to 60°C, put in N 2 The reaction was stirred at 75-85°C for 1.5 hours under the protection;

[0063] (3), add adhesion promoter, catalyst, antioxidant in turn, in N 2 Stir and mix for 1 hour at 75-85°C under protection;

[0064] (4), heat up to 100~130 ℃, vacuumize until no bubbles appear, and discharge the material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com