Method for preparing durable flame-proof cotton fabric

A durable flame retardant, cotton fabric technology, used in plant fibers, textiles and papermaking, fiber processing, etc., can solve problems such as fire accidents, and achieve the best flame retardant effect, small physical and mechanical properties, and a wide range of sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

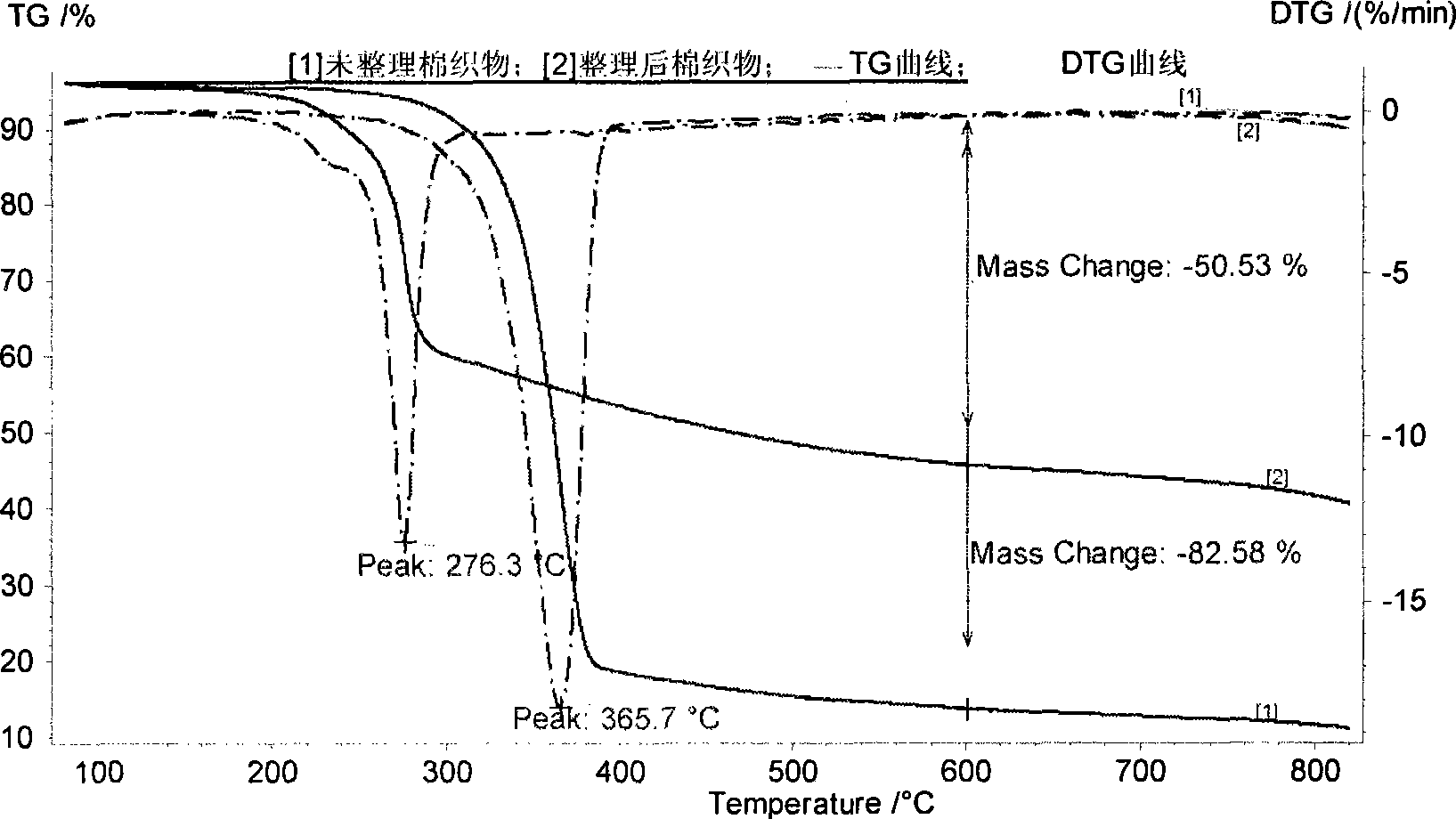

Embodiment 1

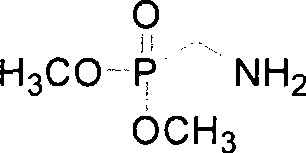

[0024] The dosage of aminomethylphosphonate (DAMP) is 150g / L, the dosage of GPTMS is 40g / L, and the pH value of the finishing solution is adjusted to 4.0 with acetic acid to prepare the flame retardant finishing solution. Soak the cotton fabric in the above-mentioned finishing liquid, soak for 20 minutes at 40°C, dipping and rolling, and the liquid retention rate is 75%. Then dry at 100°C for 3 minutes, and bake at 165°C for 3 minutes, and the flame-retardant cotton fabric can be prepared. According to the prescribed flame-retardant test standards, the flame-retardant performance: after-flame time 0s, smoldering time 0s, damaged charcoal length 11.5 cm.

Embodiment 2

[0026] The dosage of aminomethylphosphonate (DAMP) is 300g / L, the dosage of GPTMS is 40g / L, and the pH value of the finishing solution is adjusted to 4.0 with acetic acid to prepare the flame retardant finishing solution. Soak the cotton fabric in the above-mentioned finishing liquid, soak for 20 minutes at 40°C, dipping and rolling, and the liquid retention rate is 75%. Then dry at 100°C for 3 minutes, bake at 165°C for 3 minutes, and the flame-retardant cotton fabric can be prepared. According to the prescribed flame-retardant test standards, the flame-retardant performance: after-flame time 0s, smoldering time 0s, damaged charcoal length 9.2 cm.

Embodiment 3

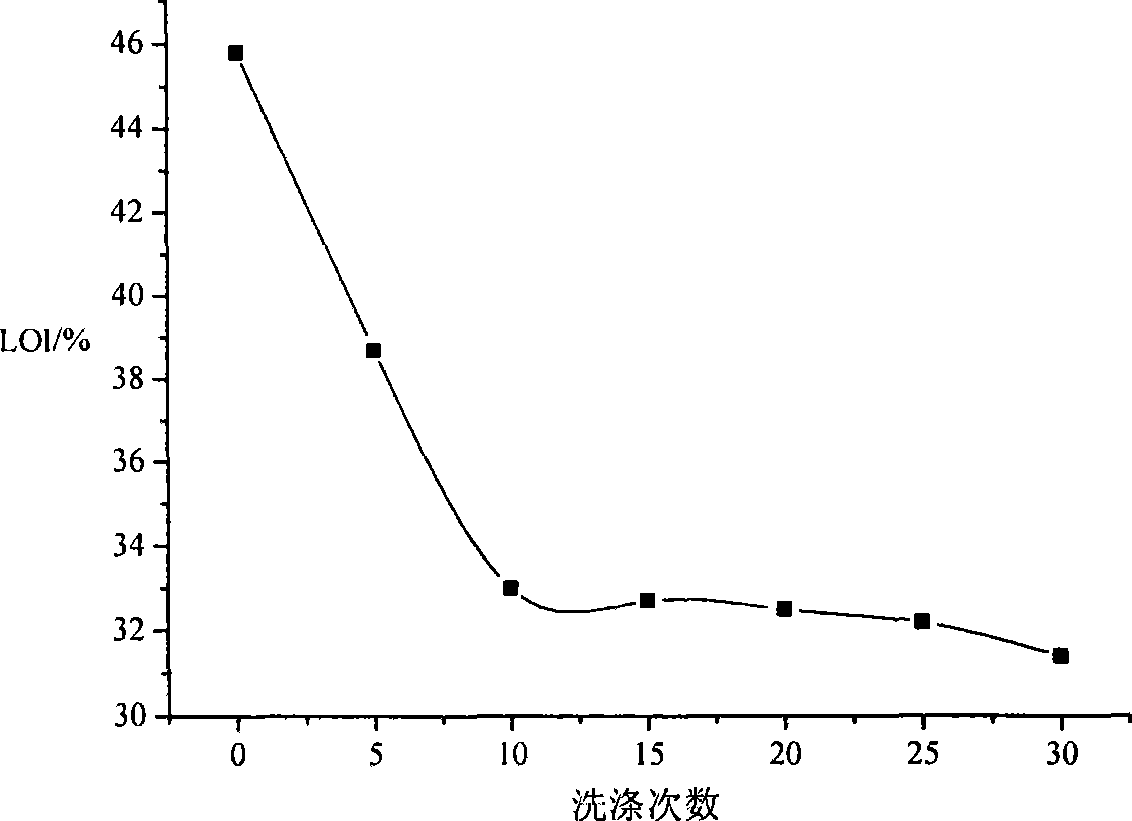

[0028] The dosage of aminomethylphosphonate (DAMP) is 300g / L, the dosage of GPTMS is 10g / L, and the pH value of the finishing solution is adjusted to 4.0 with acetic acid to prepare the flame retardant finishing solution. Soak the cotton fabric in the above-mentioned finishing liquid, soak for 20 minutes at 40°C, dipping and rolling, and the liquid retention rate is 75%. Then dry at 100°C for 3 minutes, bake at 165°C for 3 minutes, and the flame-retardant cotton fabric can be prepared. According to the prescribed flame-retardant test standards, the flame-retardant performance: after-flame time 0s, smoldering time 0s, damaged charcoal length 9.6 cm; after 10 times of washing, the flame retardant performance: the afterburning time is 0s, the smoldering time is 0s, and the length of damaged charcoal is 15.4cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com