Polypropylene-based dimethyl phosphate flame retardant and preparation method thereof

A technology of polypropylene-based dimethyl phosphate and propylene-based dimethyl phosphate, used in textiles, papermaking, fiber processing, etc., can solve the problems of harsh reaction conditions and complicated processes, and achieve high flame retardant efficiency and durability. Flame retardant effect, good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

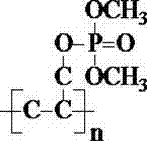

[0017] Implement the preparation method of a kind of polypropylene base dimethyl phosphate flame retardant of the present invention, this method is to react propenyl alcohol and phosphorus oxychloride, diethyl ether or ethyl acetate are solvent, take triethylamine or pyridine as acid-binding agent , at 0°C, stirred and reacted for 6 hours, then added dropwise a mixture of methanol and triethylamine, reacted for another 3 hours, filtered and evaporated to obtain propenyl dimethyl phosphate monomer; then propenyl dimethyl Phosphate monomer and potassium persulfate react in aqueous solution or emulsion, and the reaction mass ratio is propylene dimethyl phosphate monomer: potassium persulfate: Span-60: deionized water = 40~45: 2~10: 0~10: 40~45, adjust the pH value to 5~7, microwave radiation, power: 220~700W, control temperature: 65~95℃, reaction time: 3~10 minutes, get the filtrate by suction filtration, separate Remove the supernatant, and then distill to obtain polypropylene-b...

specific Embodiment approach 2

[0018] Implement the preparation method of a kind of polypropylene base dimethyl phosphate flame retardant of the present invention, its concrete method is to carry out according to the following steps:

[0019] (1) Add diethyl ether and phosphorus oxychloride into the reaction kettle, the molar ratio is 4:1, diethyl ether is used as solvent;

[0020] (2) Add a mixture of propenol and triethylamine with a molar ratio of 1:1 to the reaction kettle dropwise, stir and react for 6 hours, control the temperature at 0°C, and obtain the compound (1) as shown in the reaction formula (1) ):

[0021]

[0022] Reaction formula (1) Compound (1)

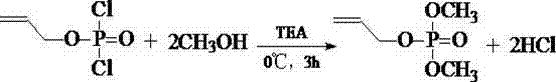

[0023] (3) React the mixture of compound (1) with methanol and triethylamine through reaction formula (2) for 3-6 hours; let stand for 12 hours, filter with suction to obtain the filtrate, and evaporate at 50-70°C to obtain compound (2) - propenyl dimethyl phosphate;

[0024]

[0025] Reaction formula (2) Compound (...

Embodiment 1

[0034] (1) Add 4 mol of ether and 1 mol of phosphorus oxychloride into a three-necked flask, and use ether as a solvent;

[0035] (2) Add a mixture of 1 mol of allyl alcohol and 1 mol of triethylamine dropwise into the reaction kettle, stir and react for 6 hours, and control the temperature at 0°C;

[0036] (3) After the reaction is completed, add dropwise a mixture of 2.2 mol methanol and 2 mol triethylamine, react for 3 hours, and let stand for 12 hours;

[0037] (4) The filtrate was obtained by suction filtration, and was evaporated by a rotary evaporator to obtain propenyl dimethyl phosphate, and the rotary evaporation temperature was 50°C;

[0038] (5) Put 45 parts by mass of propenyl dimethyl phosphate, 45 parts of water, 6 parts of Span-60, and 4 parts of persulfate into the beaker. The reaction temperature is controlled at 80°C, and the pH value is adjusted with formic acid 7. Heating by microwave, set the power to 400W, and the reaction time is 6 minutes;

[0039] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com