High-temperature-resistant and flame-retardant cable material and preparation method thereof

A kind of flame retardant cable material, high temperature resistance technology, applied in the direction of insulated cables, cables, circuits, etc., to achieve good wear resistance, obvious flame retardant effect, good elasticity and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

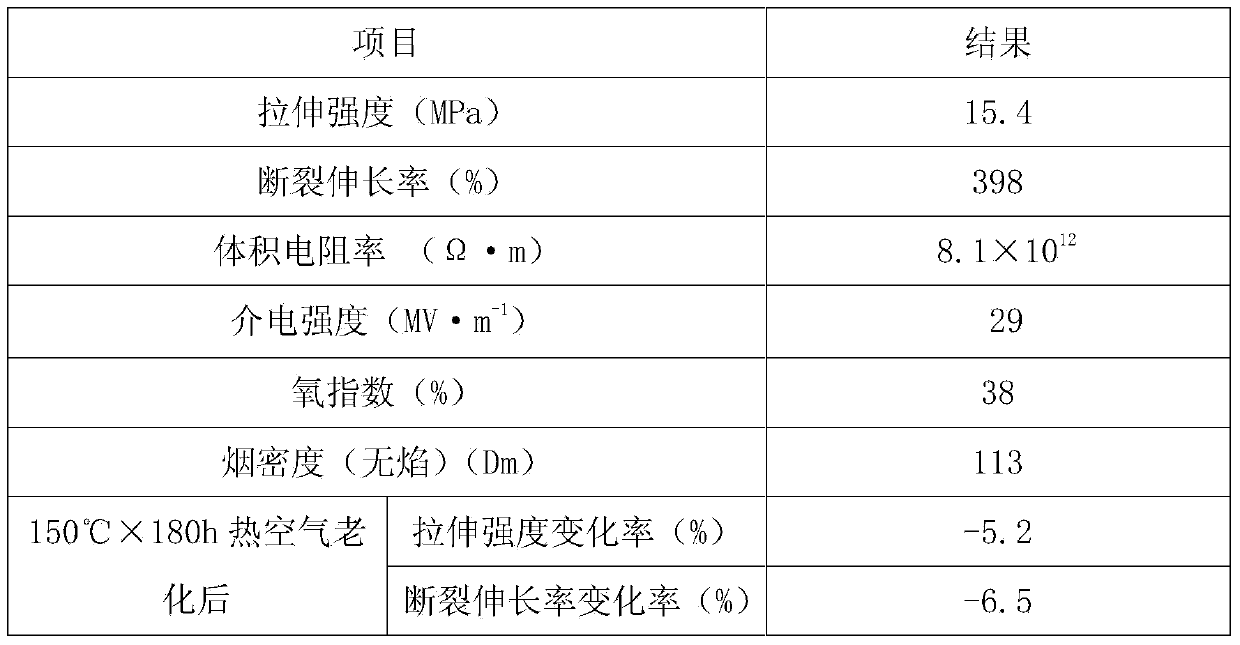

Examples

Embodiment Construction

[0012] A high-temperature-resistant flame-retardant cable material, made of the following raw materials in weight (kg): high-density polyethylene 60, EPDM rubber 30, thermoplastic polyurethane elastomer 10, tert-butyl peroxybenzoate 2, methyl Zinc acrylate 1.5, isopropyl tris(dioctyl pyrophosphate acyloxy) titanate 0.8, tall oil 6, accelerator TMTD3, antioxidant ZMTI1, acetyl triethyl citrate 7, magnesium hydroxide 12,2 -3, ferric oxide 1.5, zinc oxide 4, red phosphorus 8, dibasic lead phosphite 2, organic bentonite 18, nano silicon dioxide 14, composite filler 6;

[0013] The preparation method of the high-temperature-resistant flame-retardant cable material: a. Take the following raw materials by weight (kg): kaolin 15, celestite 6, corundum powder 5, nano-aluminum nitride 5, N-2-(aminoethyl)- 3-aminopropyltrimethoxysilane 2.5, triallyl cyanurate 1.5, nano-aluminum hydroxide 10, zinc stearate 2, antioxidant ODA2; b, calcining kaolin and lapis lazuli at 540°C for 3 Hours, af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com