Halogen-free flame-proof unsaturated polyester molding compound

An unsaturated, molding compound technology, applied in the field of thermosetting molding compounds, can solve the problems of partial shrinkage, bending strength and impact strength, insufficient flame retardant grade, difficult to achieve, etc., to achieve low shrinkage, good flame retardant effect, electrical Excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

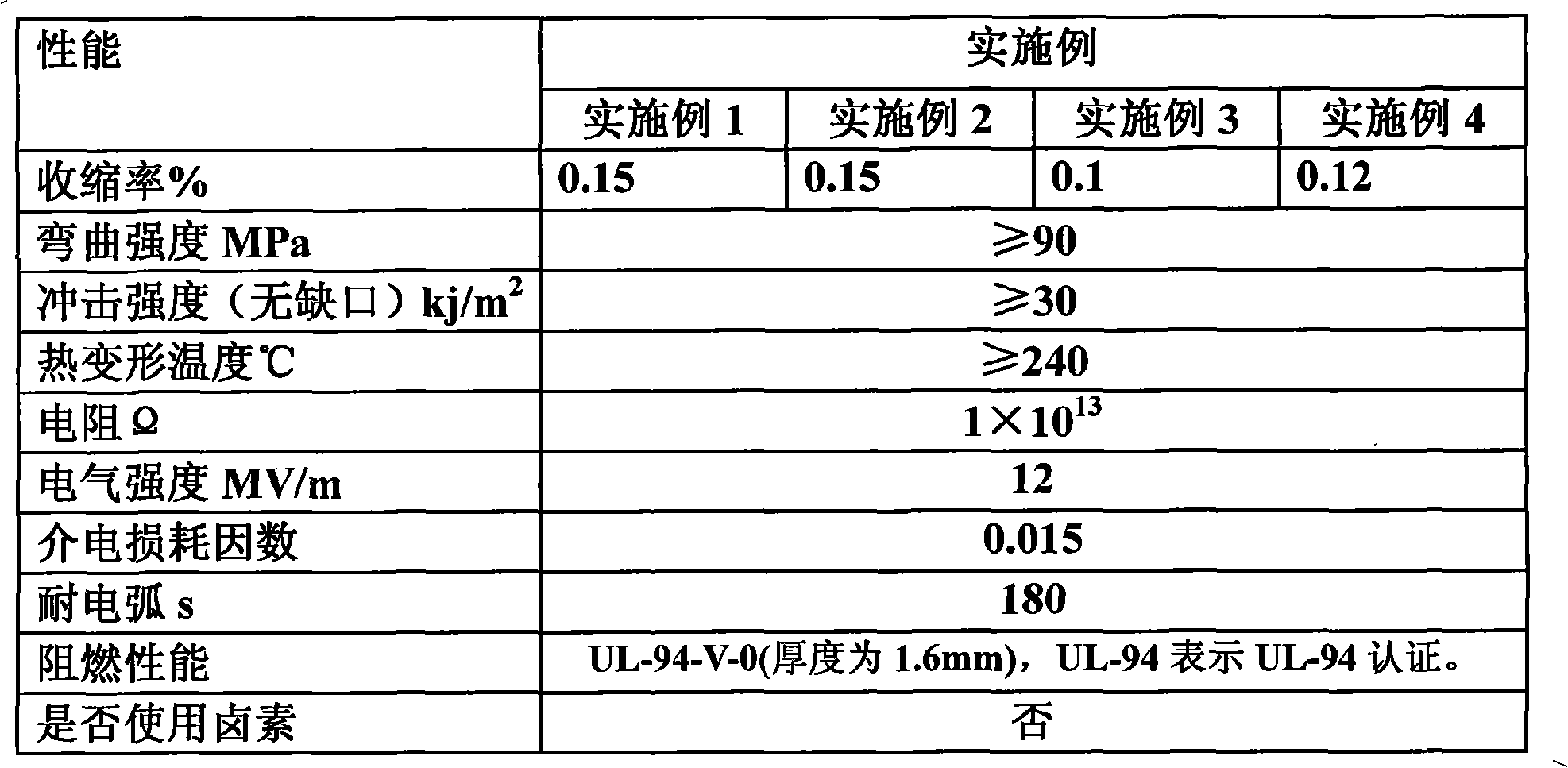

Examples

Embodiment 1

[0026] 18.5 parts of o-phthalic unsaturated polyester resin;

[0027] 11.5 parts of polyvinyl acetate (PVAc);

[0028] 0.32 parts of tert-butyl peroxybenzoate;

[0029] 0.003 parts of p-benzoquinone;

[0030] 0.23 parts of magnesium oxide;

[0031] 68 parts of aluminum hydroxide;

[0032] 10.5 parts of melamine cyanurate;

[0033] 4.5 parts of zinc borate;

[0034] 1.4 parts of calcium stearate;

[0035] Glass fiber 15.2 parts.

[0036] During specific implementation, at first the ortho-phthalic unsaturated polyester resin of the above ratio and PVAc namely polyvinyl acetate (also known as polyvinyl acetate) are added in the beater, stirred rapidly for 5 minutes, then added the p-benzoquinone of the above ratio , magnesium oxide and tert-butyl peroxybenzoate continue to stir for 25 minutes to obtain a uniform slurry, then move the evenly stirred slurry into a kneader and knead for 5 minutes, then add the melamine cyanurate in the above ratio in turn , zinc borate, calc...

Embodiment 2

[0038] 18.8 parts of isophthalic unsaturated polyester resin;

[0039] 13 parts of polymethyl methacrylate (PMMA);

[0040] 0.4 parts of tert-butyl peroxybenzoate;

[0041] 0.005 parts of p-phenol;

[0042] 0.12 parts of magnesium oxide;

[0043] 70 parts of calcium carbonate;

[0044] 12 parts of melamine phosphate;

[0045] 4.3 parts of antimony trioxide;

[0046] Zinc stearate 1.5 parts;

[0047] Glass fiber 17.5 parts.

[0048] During specific implementation, at first the m-benzene type unsaturated polyester resin of the above-mentioned ratio and PMMA namely polymethyl methacrylate are added in the beater, stirred for 5 minutes, then added p-phenol, magnesium oxide and benzoic acid peroxide of the above-mentioned ratio Continue to stir tert-butyl ester for 25 minutes to obtain a uniform slurry. Then, move the uniformly stirred slurry into a kneader and knead for 5 minutes, and then add the above-mentioned proportions of melamine phosphate, antimony trioxide, and zin...

Embodiment 3

[0050] 19.4 parts of bisphenol A type unsaturated polyester resin;

[0051] 12.3 parts of polyvinyl acetate (PVAc);

[0052] 0.45 parts of tert-butyl peroxybenzoate;

[0053] 0.004 parts of p-benzoquinone;

[0054] 0.15 parts of magnesium oxide;

[0055] 75 parts of aluminum hydroxide;

[0056] 11 parts of ammonium polyphosphate;

[0057] 2.5 parts of melamine cyanurate;

[0058] 3.8 parts of antimony trioxide;

[0059] 1.7 parts of magnesium stearate;

[0060] Glass fiber 17 parts.

[0061] During specific implementation, at first the bisphenol A type unsaturated polyester resin of the above-mentioned proportion and PVA c namely polyvinyl acetate are added in the beater, stirred for 5 minutes, then added p-benzoquinone, magnesium oxide and peroxide of the above-mentioned proportion The tert-butyl benzoate continued to stir for 25 minutes to obtain a uniform slurry. Then, the uniformly stirred slurry was moved into a kneader and kneaded for 5 minutes, and then the ammo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com