Ply rolling method for utilizing point symmetry to prepare transverse variable thickness plate strips

A technology of variable thickness, plate and strip, applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., which can solve the problems of uneven rolling of variable thickness plate and strip, and achieve coordinated deformation, cost saving, and good weight reduction and the effect of bearing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

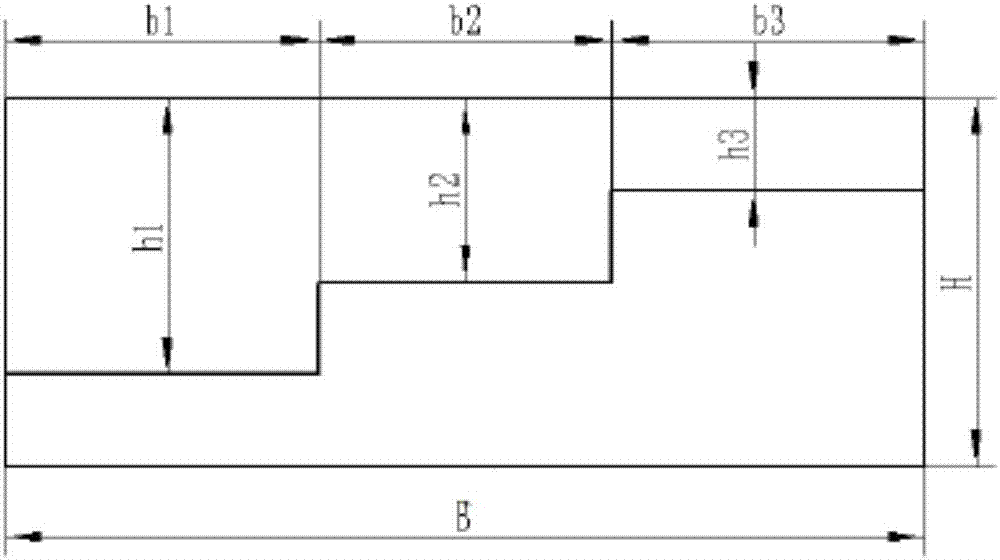

[0045] The target product is a ladder-type transversely variable thickness plate strip, which is divided into 5 thickness zones in the width direction. The zone widths are all 13mm. Image 6It is a schematic diagram of the cross-sectional shape and size of each layer of raw materials in Example 1 of the present invention. As shown in the figure, the raw material is Q235 steel, and there are two layers in total. The shape and size of the upper layer and the lower layer are the same, the length is 90 mm, and the thickness in the width direction changes in a ladder shape. Divided into 5 thickness zones, the thickness of the 5 thickness zones from small to large h5, h4, h3, h2, h1 are 5mm, 7.5mm, 10mm, 12.5mm, 15mm respectively, and the width of each thickness zone is b1, b2, b3, b4 , b5 are both 12.6mm, and the total width B is 63mm (considering the total width is 2mm). Through the following steps, the target product is finally obtained:

[0046] The rolling mill selected in th...

Embodiment 2

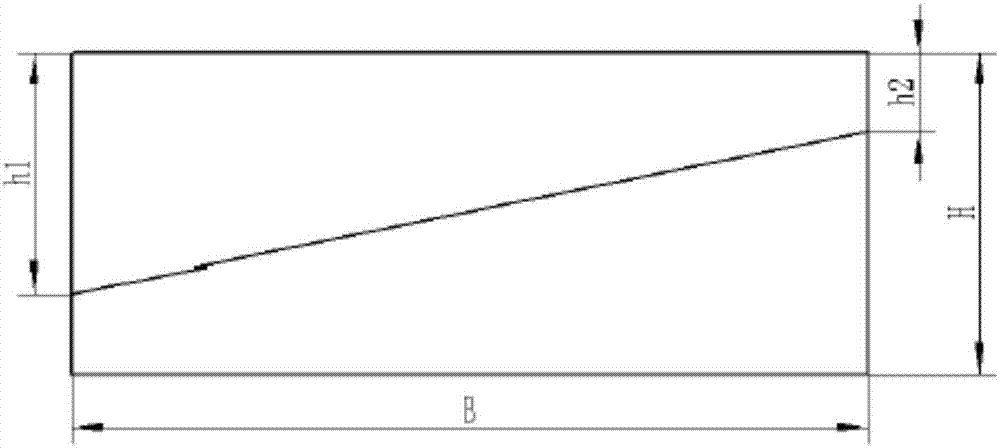

[0059] The target product is a wedge-shaped strip with a width of 300mm, a thickness of 10mm at the thickest point, and a thickness of 2mm at the thinnest point. Figure 7 It is a schematic diagram of the cross-sectional shape and size of each layer of raw materials in Example 2 of the present invention. As shown in the figure, the raw material is pure copper with a Cu content of 99.99%. There are two layers of raw materials. The upper layer and the lower layer have the same shape and size, and the shape is wedge-shaped. is 800mm, the width B is 300mm, the thickness h1 at the thickest part is 25mm, and the thickness h2 at the thinnest part is 5mm. Through the following steps, the target product is finally obtained.

[0060] The rolling mill selected in the embodiment of the present invention is a two-roll reversing rolling mill, and the rolling speed adopted is 0.2 m / s.

[0061] The preparation method of the lateral variable thickness plate and strip in this embodiment, the s...

Embodiment 3

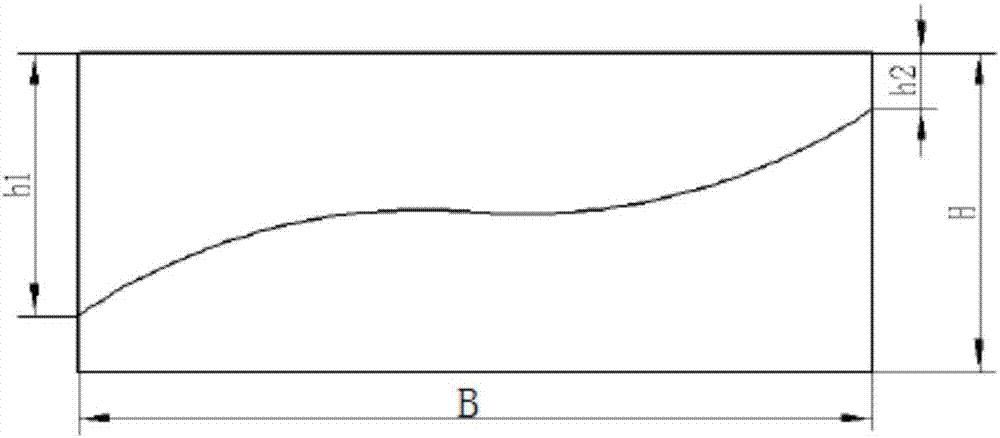

[0073] The target product is a transversely variable-thickness plate strip consisting of three parts: the thick zone, the transition zone and the thin zone. The width is 40mm. Figure 8 It is a schematic diagram of the cross-sectional shape and size of each layer of raw materials in Example 3 of the present invention. As shown in the figure, the raw material is 45# steel, and there are three layers of raw materials. The upper layer and the lower layer have the same shape and size. Three parts of the thin zone, the length is 400mm, the thickness of the thick zone h1 is 20mm, the thickness of the thin zone h4 is 10mm, the width of the thick zone b1 is 39.25mm, the width of the thin zone b3 is 78.5mm, the width of the transition zone b2 is 39.25mm, and the total width is B It is 157mm (considering the total width is 3mm); the thickness h2 of the thin area on both sides of the middle layer is 10mm, the maximum thickness h3 of the thicker area in the middle is 20mm, the widths of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com