Preparation method for chopped silicon carbide fiber reinforced aluminosilicate polymer composite material

A technology of chopped silicon carbide and aluminosilicate, which is applied in the field of composite material preparation, can solve the problems of brittleness, low mechanical strength, toughness, and limitations, and achieve excellent mechanical properties, improved thermophysical properties, high strength and toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0021] Embodiment 1: The preparation method of the chopped silicon carbide fiber reinforced aluminosilicate polymer composite material described in this embodiment is completed according to the following steps:

[0022] 1. Calcining the aluminosilicate raw material at a temperature of 600°C to 900°C for 1h to 5h to obtain an active aluminosilicate raw material;

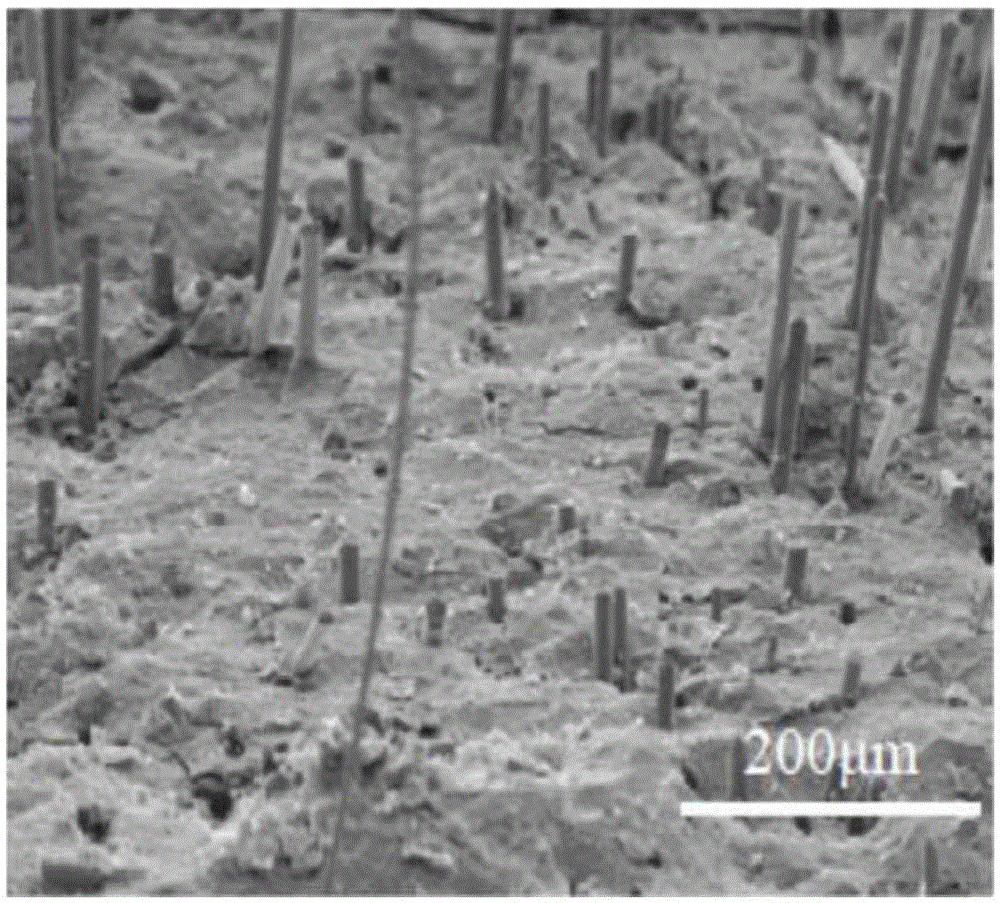

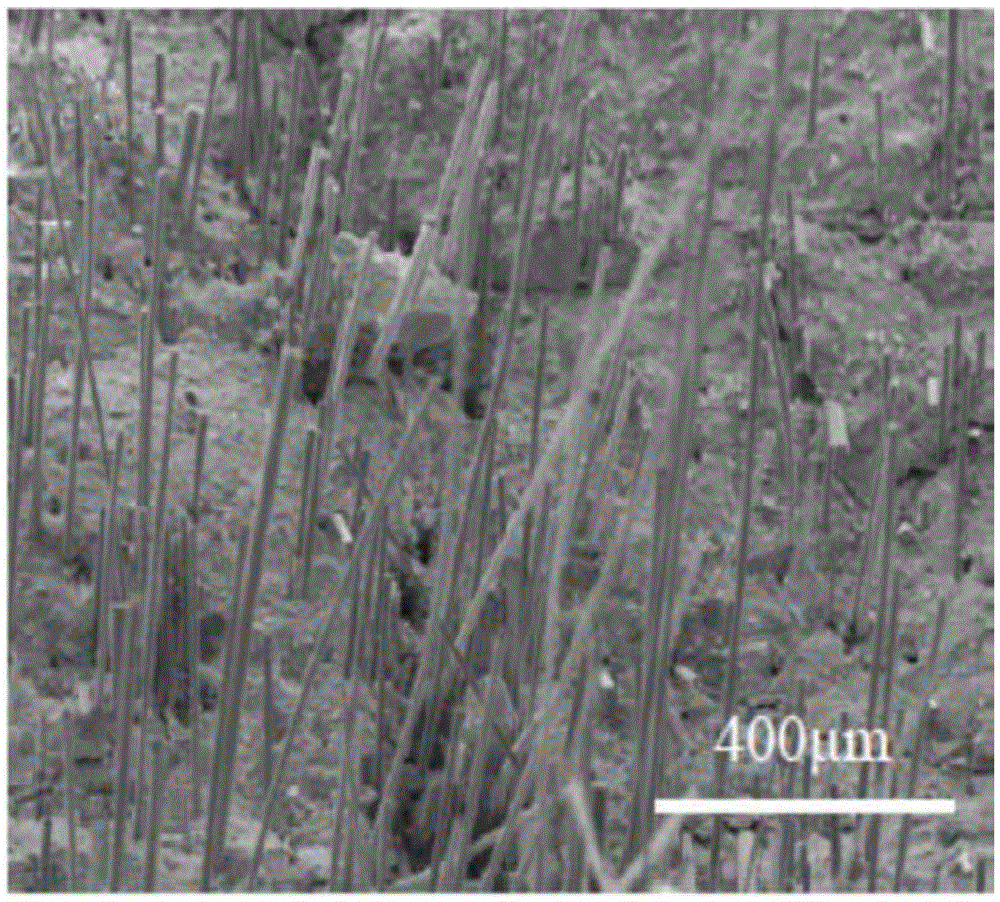

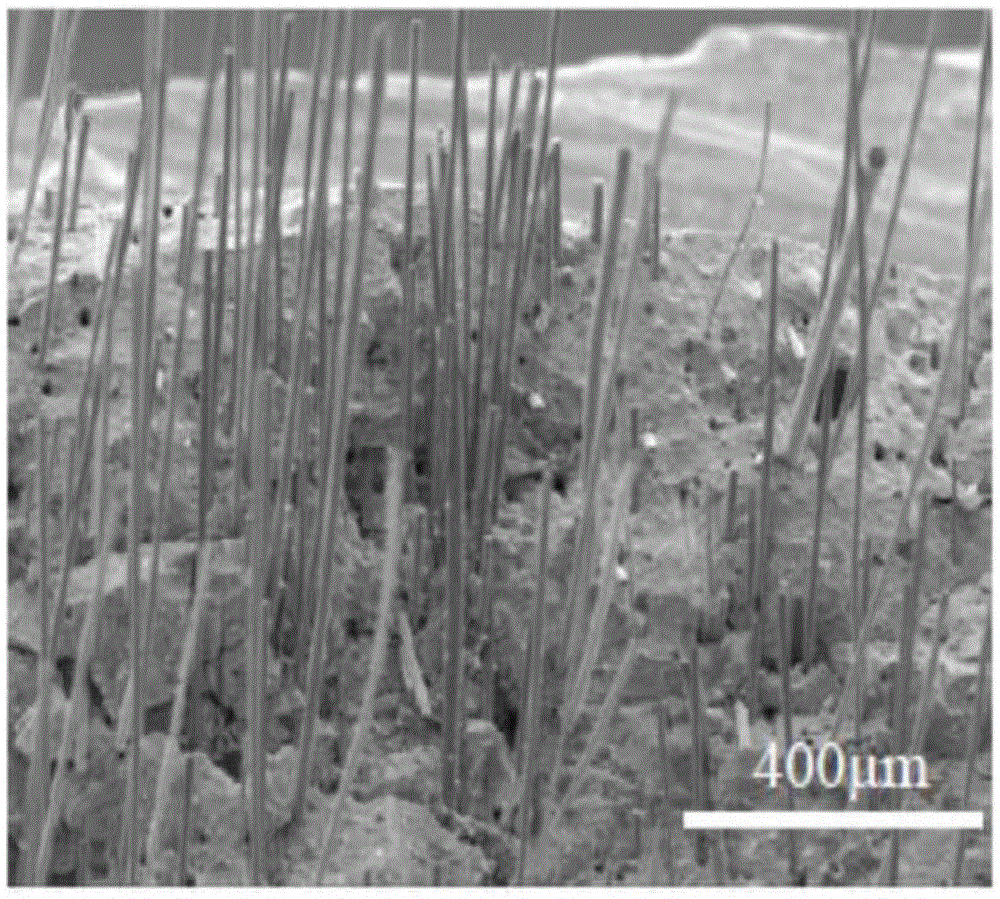

[0023] 2. Ball milling and mixing the active aluminosilicate raw material and chopped silicon carbide fiber at room temperature for 24h to 48h to obtain a ball milling mixture;

[0024] The length of the chopped silicon carbide fibers is 2 mm to 10 mm, and the volume percentage of the chopped silicon carbide fibers in the ball milling mixture is 0.5% to 5%;

[0025] 3. Add the alkali metal hydroxide into the silica sol, and stir it magnetically for 48 hours to obtain the alkali excitation solution;

[0026] The mol ratio of described alkali metal hydroxide and silicon dioxide in the silica sol is 1:1;

[0027] 4. Mi...

specific Embodiment approach 2

[0032] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the aluminosilicate raw material in step 1 is kaolin, clay, fly ash or blast furnace slag. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0033] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the alkali metal hydroxide described in step 3 is sodium hydroxide, potassium hydroxide or cesium hydroxide. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com