Process for rebuilding double arch bridge by replacing arch style construction on arch with continuous slabs

A double-curved arch bridge and continuous slab technology, which is applied in building structures, buildings, arch bridges, etc., can solve the problems of poor overall deformation coordination, insufficient overall stiffness, and low design load, so as to improve the overall load bearing capacity and enhance the lateral The effect of improving the integrity and carrying capacity

Inactive Publication Date: 2008-10-22

江西中煤建设集团有限公司

View PDF0 Cites 20 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Because: 1. The stress characteristics of the double-curved arch are transmitted from the bridge deck to the belly arch and the solid belly section, and the solid belly section is transmitted to the arch wave, and then the force is transmitted to each arch rib of the rib-shaped main arch ring by the arch wave; The abdominal arch directly transmits the force to the arch rib through the arch pier, and the arch rib transmits the above-mentioned force it bears to the bridge pier and so on. The lateral thrust resistance of the ribs; therefore, the overall stress situation of the double-curved arch bridge is more complicated; 2. Compared with the box-shaped or plate-shaped main arch ring, the rib-shaped main arch ring has poor vertical and horizontal rigidity; 3 1. The overall deformation coordination is poor; 4. The joint surface between each arch rib and arch wave of the rib-shaped main arch ring is too small, the cross-sectional force is complicated, and the integrity is poor; 5. The overall rigidity of the transverse connection between each arch rib of the rib-shaped main arch ring Insufficient and the lateral thrust resistance stiffness of each arch rib itself is insufficient; 6. The design load at that time was low

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

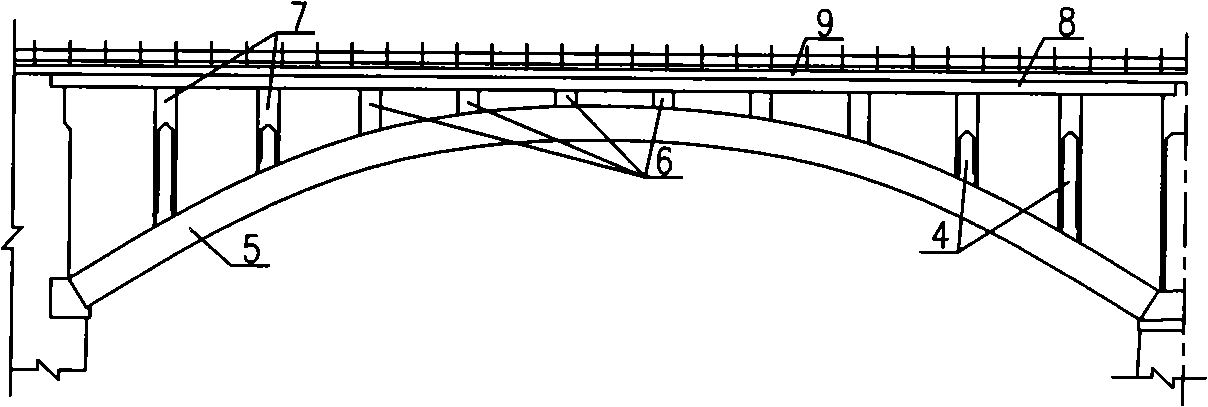

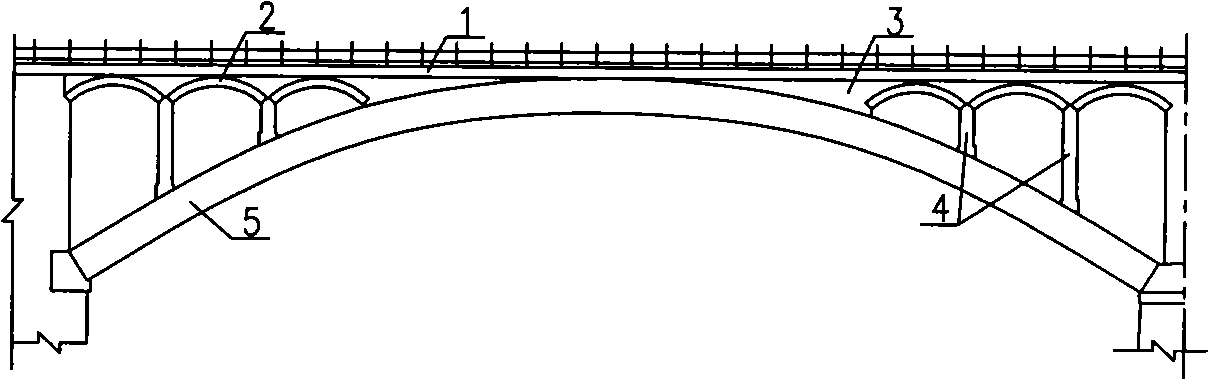

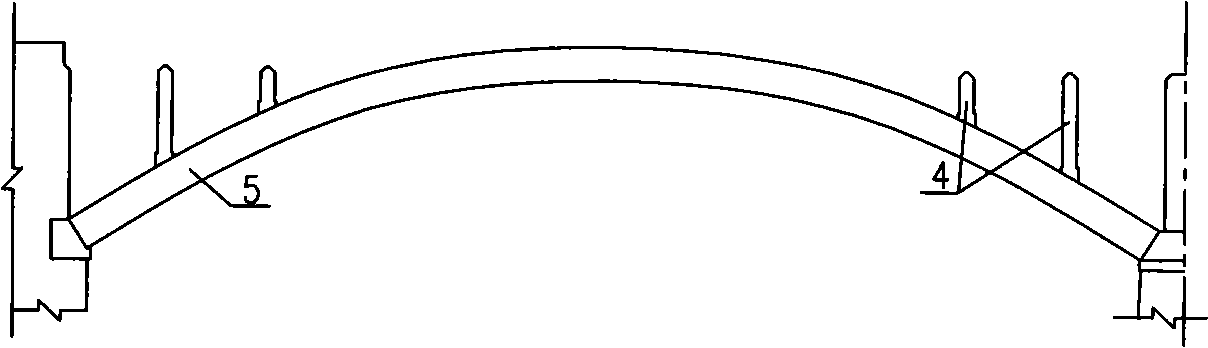

The invention relates to a reforming method of replacing double arch bridges in arched spandrel structure with continuous slabs. The method comprises the following steps that: a bridge floor system, a spandrel arch ring and a solid web section of a double arch bridge in arched spandrel structure are dismantled first; a plate girder pier is arranged on a ribbed main arch ring, and a former spandrel arch pier is heightened to form another plate girder pier, ensuring that the plate girder piers are identical in interval and horizontal height; bridge piers are heightened to ensure that the horizontal height of the bridge piers is equal to the plate girder piers; continuous slabs are cast on the plate girder piers and the bridge piers, and then the continuous slabs are paved with a bridge deck. The method improves the stress state of the ribbed main arch ring and ensures that the stress of the ribbed main arch ring tends to be more reasonable; as the arched spandrel structure is replaced with the continuous slabs, the dead load weight of an arch is reduced, and the bearing capacity of the bridge is improved correspondingly; the method saves the occupancy of natural resources and economic resources, which is caused by abandonment, old bridge demolishment and reconstruction, has the reinforcement cost which is 50 percent of new construction cost, and avoids the pollution on the natural environment caused by abandonment and old bridge demolishment.

Description

Reconstruction method of double-curved arch bridge with continuous slabs instead of arch-over-arch buildings technical field The invention relates to a reconstruction method of a bridge, in particular to a reconstruction method of a double-curvature arch bridge in which a continuous plate replaces an arch-overarch building. Background technique The double-curved arch bridge is still a unique bridge type in my country, which has the flavor and characteristics of the Chinese nation. Because the bridge type has the characteristics of beautiful appearance, low cost and simple construction technology, a large number of bridges were built in my country in the 1960s and 1980s. The structure forms the bridge to meet the needs of transportation. The bridge type is generally composed of arched arch buildings (including belly arch piers, belly arch rings, solid belly sections and deck systems), rib-shaped main arch rings, substructures (piers, abutments) and protective structures. Be...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E01D21/00E01D24/00E01D22/00E01D4/00

Inventor 谌润水吴利平谌洁君

Owner 江西中煤建设集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com