Inner loop end block type ball screw pair

A ball screw pair and internal circulation technology, applied in the direction of belts/chains/gears, mechanical equipment, transmission devices, etc., can solve the problems of limited number of bearing turns, poor manufacturability, and uneven transition, etc., to achieve load bearing The effect of large capacity, good processing technology and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

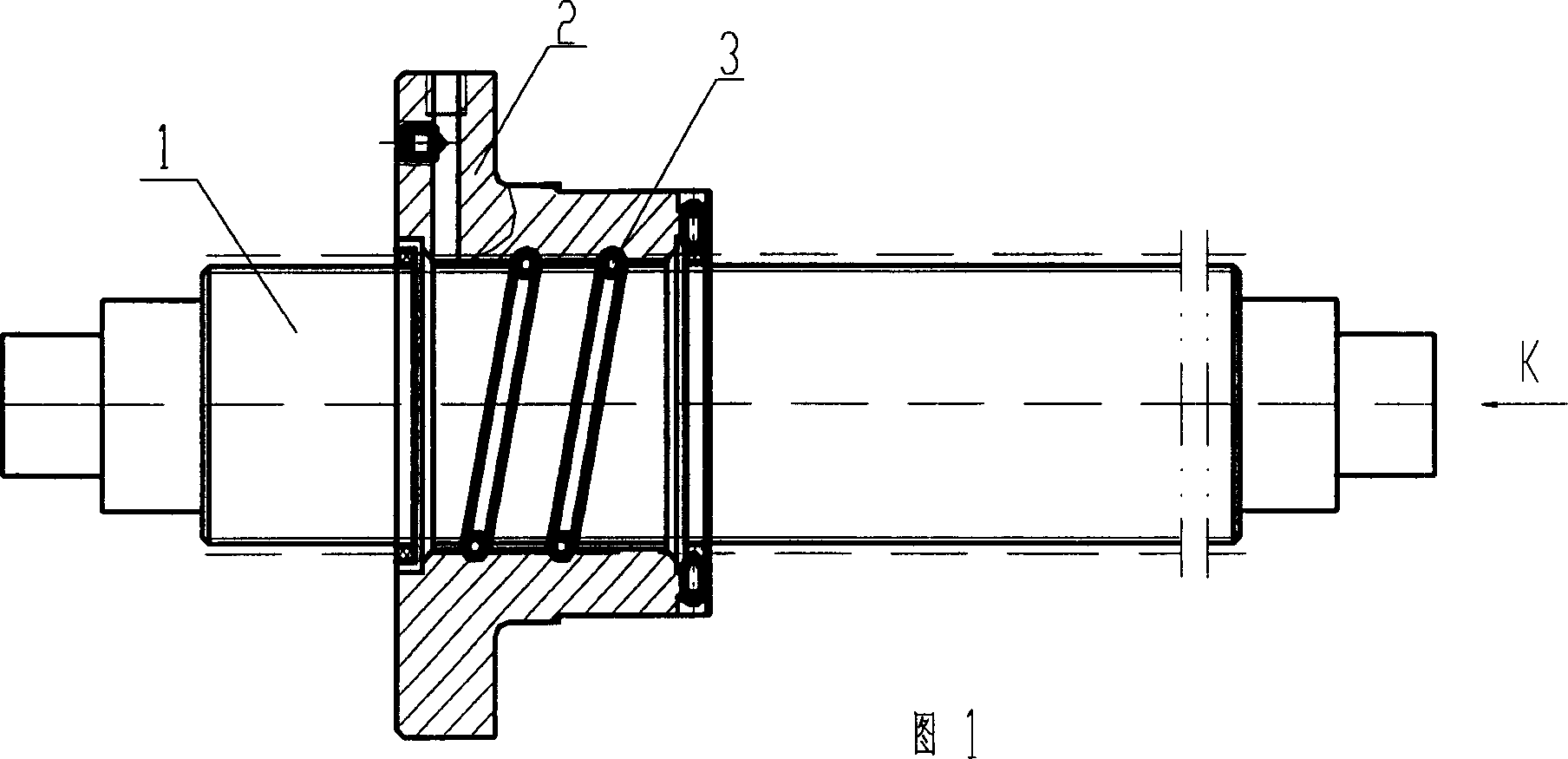

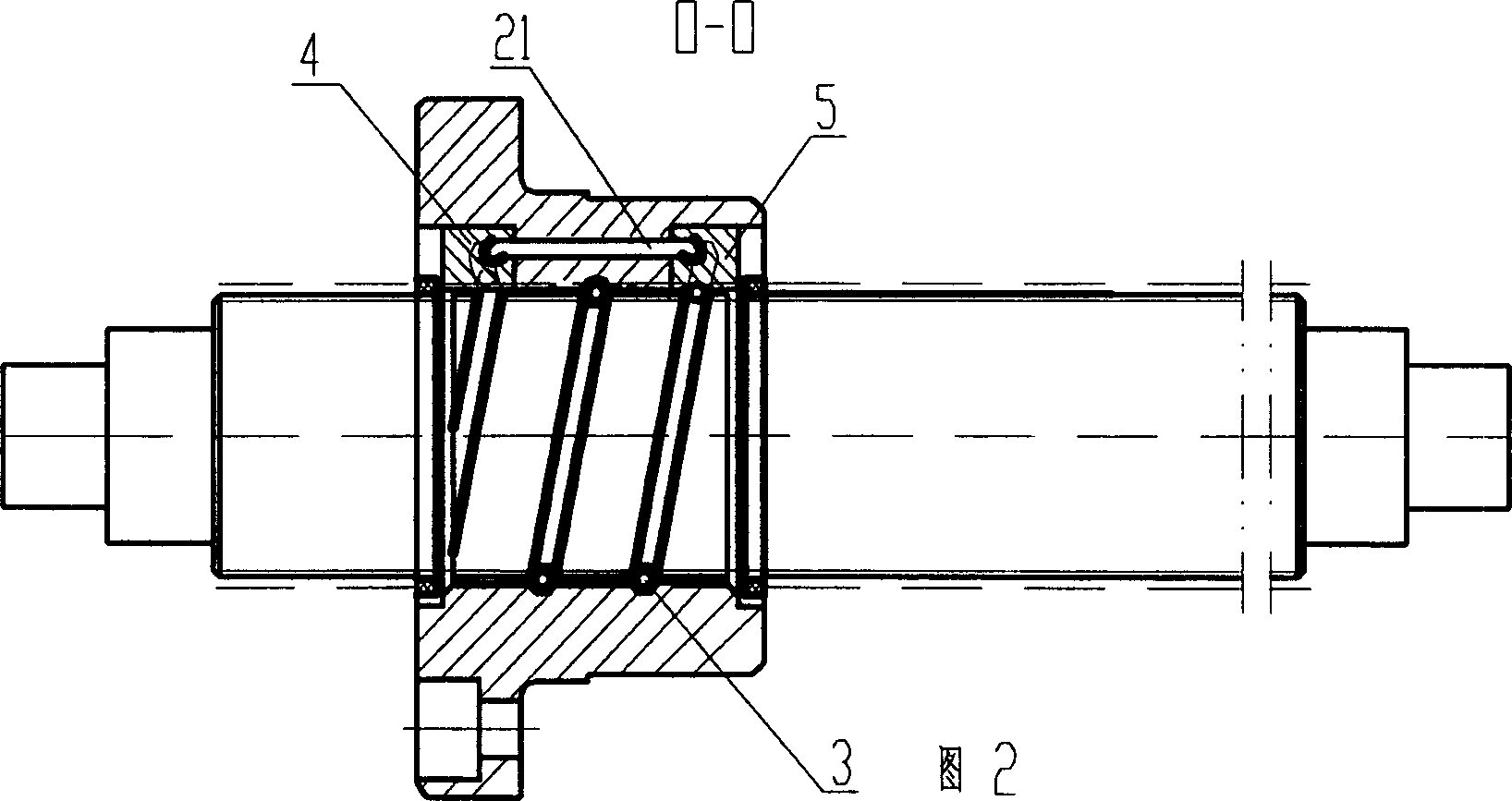

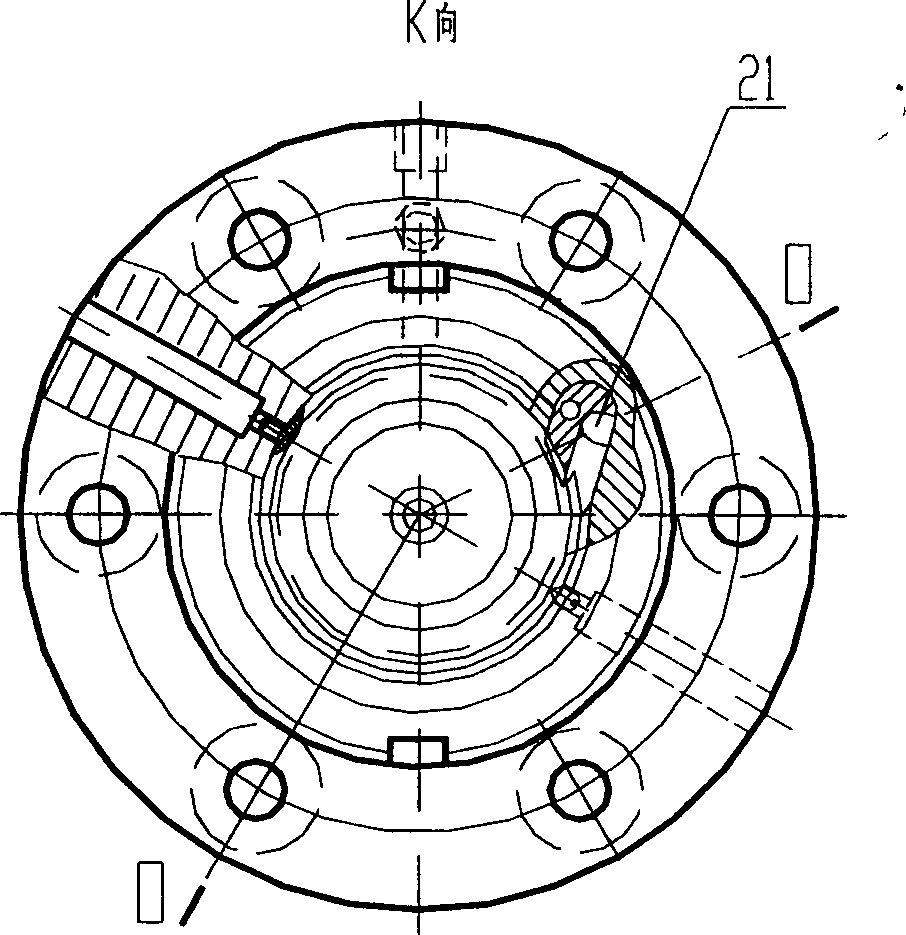

[0017] An inner circulation end block type ball screw pair, which is composed of a screw 1, a nut 2 and a steel ball 3, the screw 1 and the nut 2 are respectively provided with raceway grooves, and the steel ball 3 is arranged on the screw 1 and the steel ball In the steel ball raceway formed by the combination of the raceway grooves of the nut 2, it is characterized in that a through hole 21 is provided on the nut 2, and reverser grooves are arranged at both ends of the nut 2, and each reverser groove is respectively provided with The return device 4 or 5, the return device is a return block, on the return block is provided with a return raceway 6 and a tongue 7, the port of the return raceway 6 is connected with the steel ball raceway, and the return roller The other port of the track 6 communicates with the through hole 21 on the nut 2, and the tongue 7 on the return block is located in the ball raceway. In this embodiment, the nut 2 is a flange nut. In the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com