Manned submersible device observation window transparent piece fastening structure and method

A technology for manned submersibles and fastening structures, which is applied to door/window accessories, switches with braking devices, ship components, etc., and can solve stress concentration, flatness errors, and differences in the tightening degree of flange fastening bolts and other problems, to achieve the effect of increasing the load bearing capacity, improving assembly interchangeability, and avoiding assembly stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further described below in conjunction with specific examples.

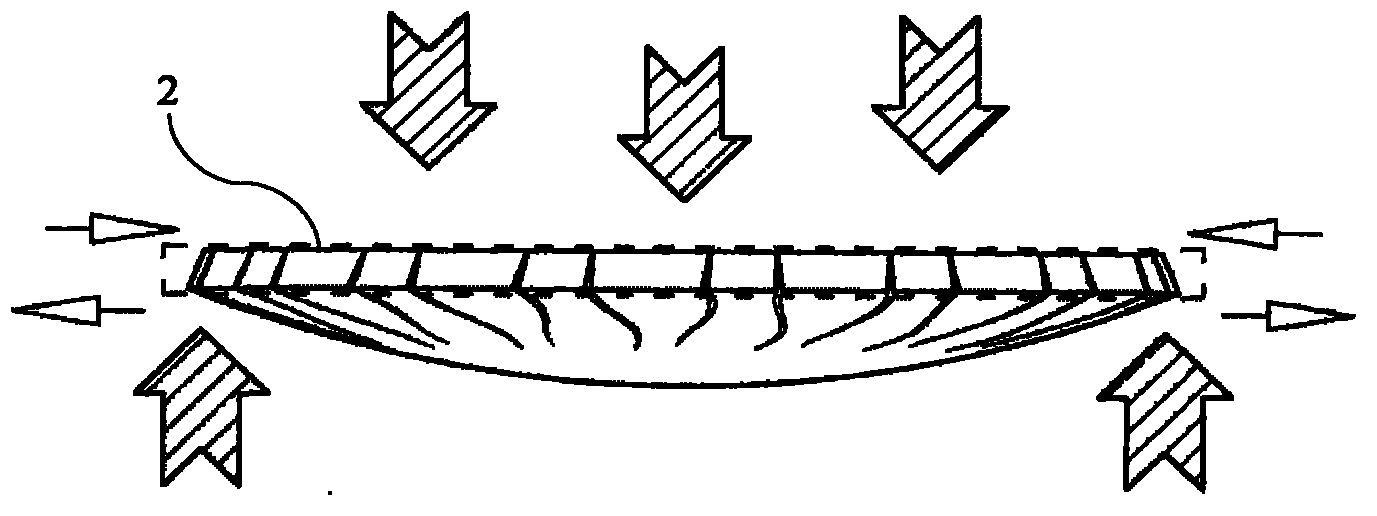

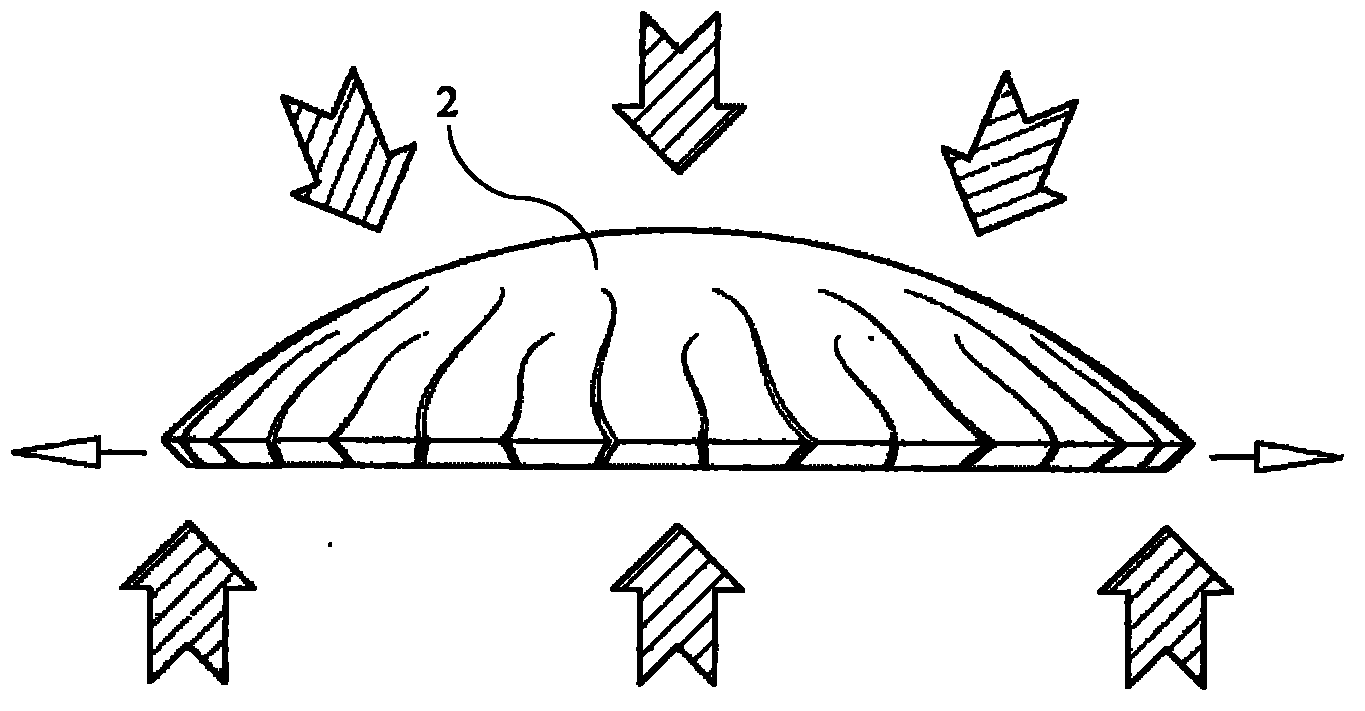

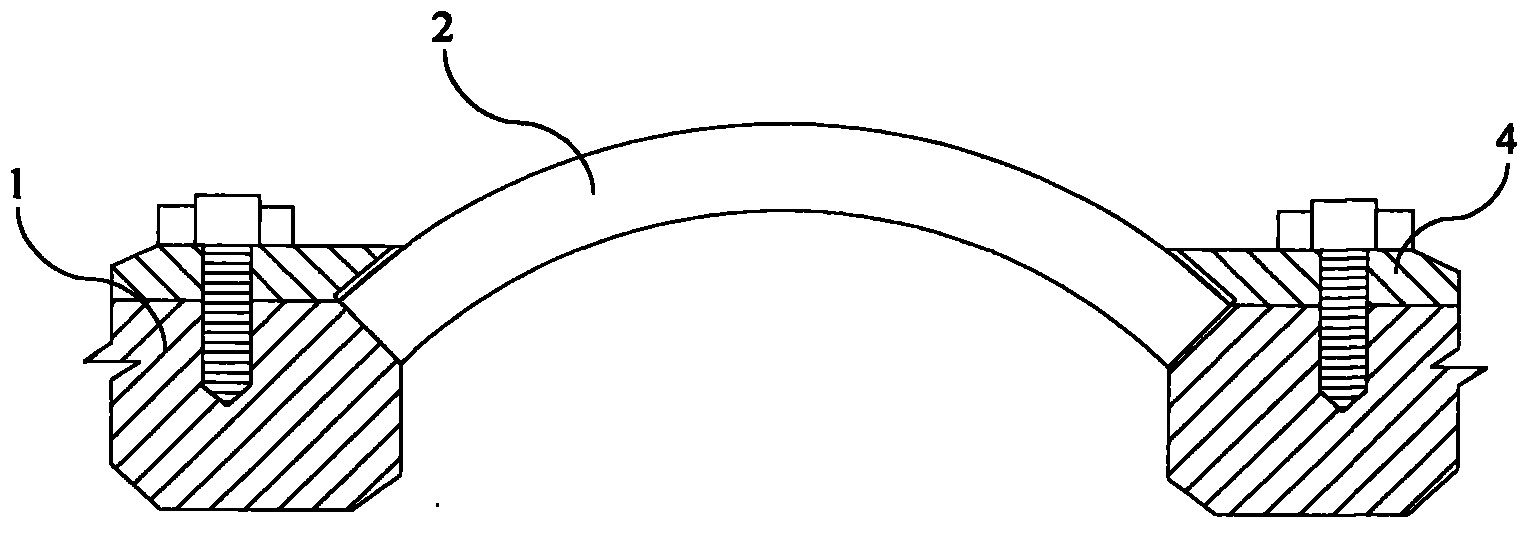

[0070] See Figure 9-11 , in the first preferred embodiment of the present invention, a kind of fastening structure of the observation window transparent part of the manned submersible of the present invention comprises the submersible shell and the observation window transparent part 2 installed in the shell; the periphery of the transparent part 2 Combined with a frame 3, the frame 3 is formed with a mounting structure that matches the housing 1, the frame 3 includes a pressing component 31 and a fastening component 32, and the pressing component 31 and the transparent part 2 press the fastening component 32 to generate prestress and then fasten Transparent part 2.

[0071] see Figure 14-15 , the fastening component 32 includes two bow-shaped arms 321 symmetrically clamped on the transparent part 2, and its material should be selected from a material with considerable str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com