Laser welding method for ultrasonic vibration along with welding

A technology of ultrasonic vibration and laser welding, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of low frequency and the effect of weld uniformity, reduce residual stress, weld uniformity, and improve fatigue performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

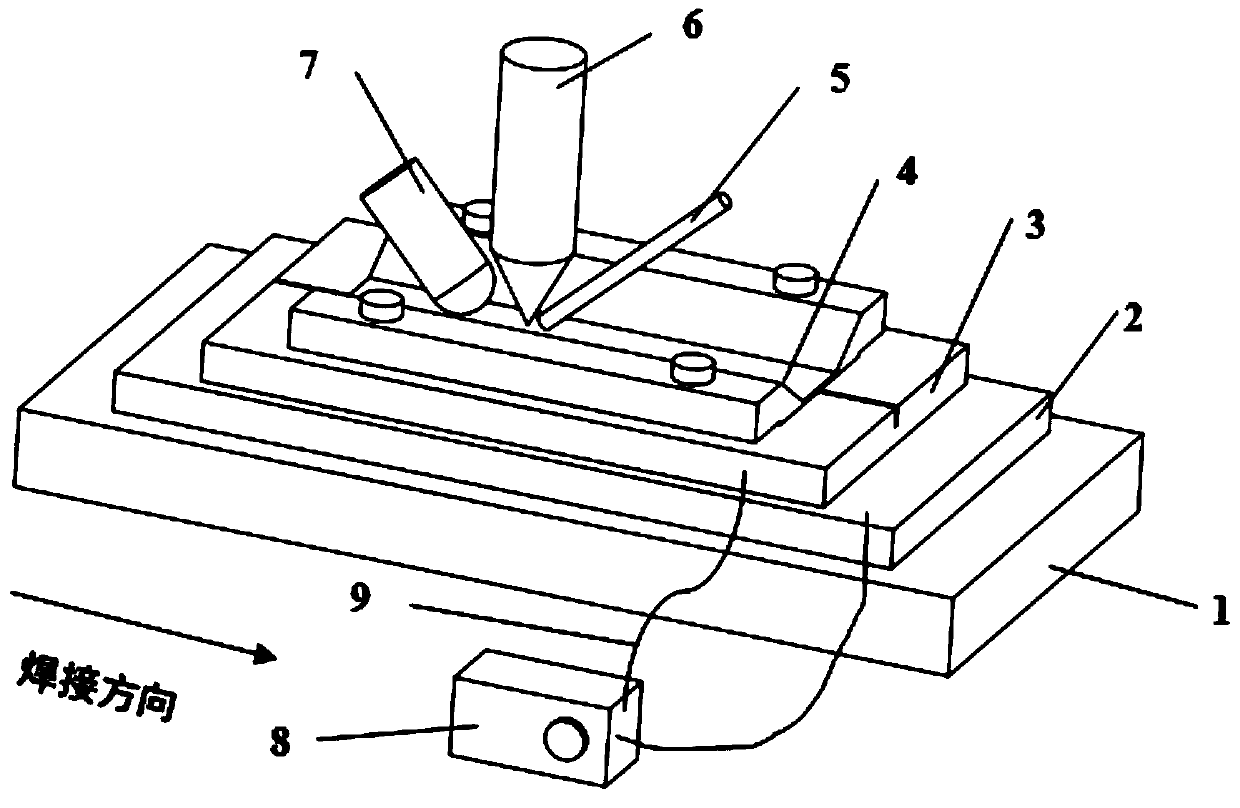

[0031] A. Place the Hastelloy C-276 plate with a thickness of 0.5mm on the fixture 3 and clamp it with copper clamps, and the distance between the clamps is 6mm. Place the preheating plate 2 on the workbench, place the fixture 3 above the preheating plate 2, and fix the positions of the three.

[0032] B. Adjust the ultrasonic parameters. Adjust the ultrasonic head 7 so that it is 14 mm directly behind the welding position to ensure that the position of the ultrasonic head 7 acts on the preheated thermoplastic zone and can conduct ultrasonic waves into the molten pool. Adjust the angle of the ultrasonic head 7 so that the axis of the ultrasonic head 7 forms an angle of 30° with the horizontal. Adjust the position of the ultrasonic head 7 so that its top is 0 mm away from the surface of the workpiece; after the position of the ultrasonic head 7 is determined, fix it with the cantilever of the machine tool to ensure that the relative position of the two does not change during t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com