Hot melt adhesive assisted laser shock peening method for small hole of airplane structural part

A technology of laser shock strengthening and aircraft structural parts, which is applied in the field of laser shock strengthening, can solve the problems of reducing the structural quality of small holes, ablation of the inner wall of small holes, and damage of sacrificial layers, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

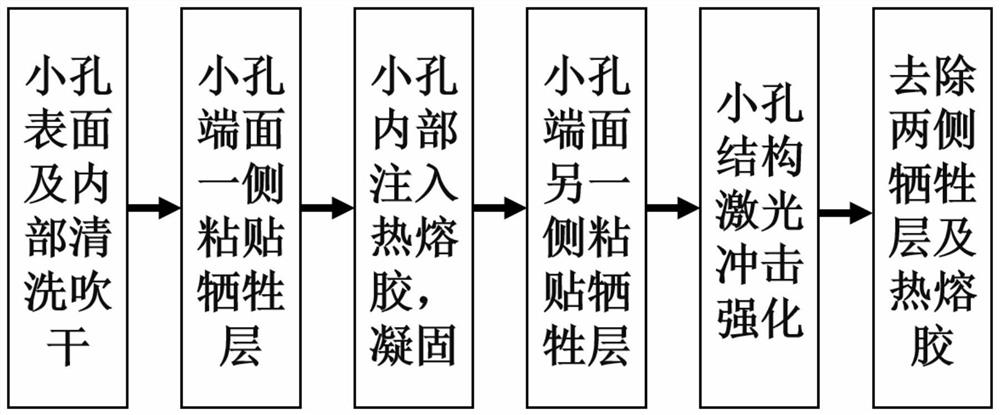

[0023] This embodiment is a laser shock strengthening method for small holes of aircraft structural parts, and the operation process is as follows figure 1 The specific process is as follows:

[0024] 1. For the 7050 aluminum alloy aircraft workpiece with a small hole structure of 5mm in diameter, put it in an ultrasonic cleaning machine for cleaning, dry it with nitrogen and install it on the fixture, paste 3M black tape on the end face of one side of the small hole, and the area where the black tape is pasted exceeds the small hole. more than 5 times the diameter.

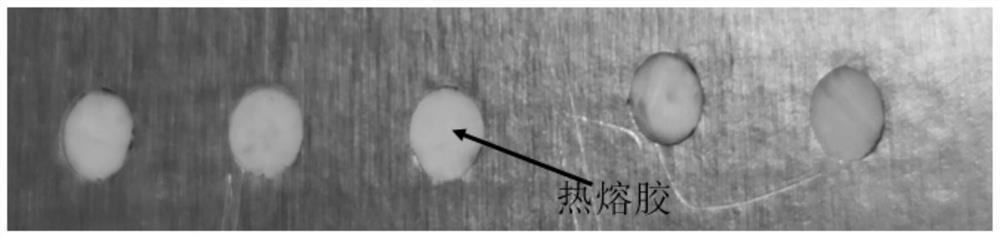

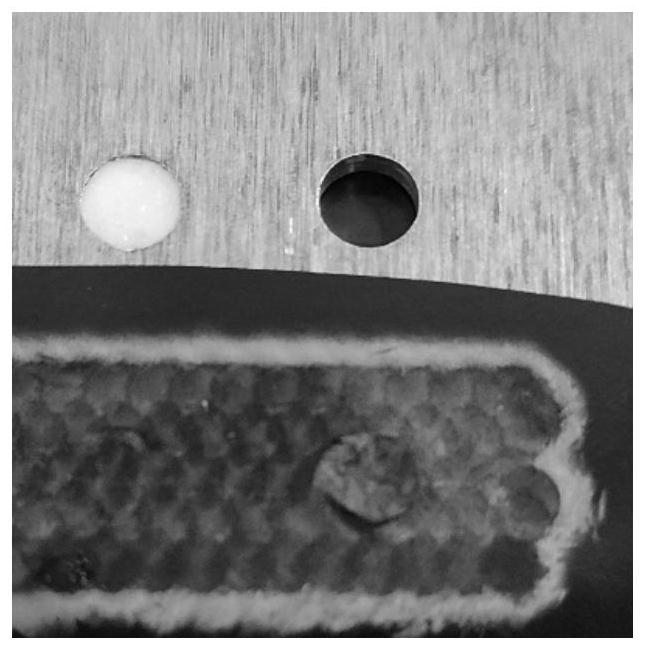

[0025] 2. Turn the other side of the small hole upward, and use a glue gun to inject liquid hot-melt glue into the small hole. The composition of the hot-melt glue by weight percentage is: ethylene-vinyl acetate copolymer (EVA) 35%, Terpene Resin 10%, C9 Petroleum Resin 15%, Paraffin 5%, Calcium Carbonate 30%, Dibutyl Phthalate 3%, Silica 2%. The power of the glue gun is 60W. After the hot melt adhesive is soli...

Embodiment 2

[0029] This embodiment is a laser shock strengthening method for small holes of aircraft structural parts, and the specific process is as follows:

[0030] 1. For the 7050 aluminum alloy aircraft workpiece with 5mm small hole structure, put it in the ultrasonic cleaning machine for cleaning, dry it with nitrogen and install it on the fixture, paste 3M black tape on the end face of the small hole structure, and the sticking area of the black tape exceeds the small hole more than 5 times the diameter.

[0031] 2. With the other side of the small hole facing upward, use a glue gun to inject liquid hot melt adhesive into the small hole. The composition of the hot melt is the same as that of Example 1. The power of the glue gun is 100W. After the hot melt glue is solidified, use a knife to remove the hot glue protruding from the surface and paste the black glue layer.

[0032] 3. Apply a water film of a confinement layer to the area to be strengthened, and strengthen the end fac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com