Method for eliminating residual stress of aluminum alloy component formed by selective laser melting

A technology for selective laser melting and aluminum alloy components, applied in the field of material processing, can solve the problems of reduced material strength and inability to play a bearing role of structural components, and achieve the effect of ensuring mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

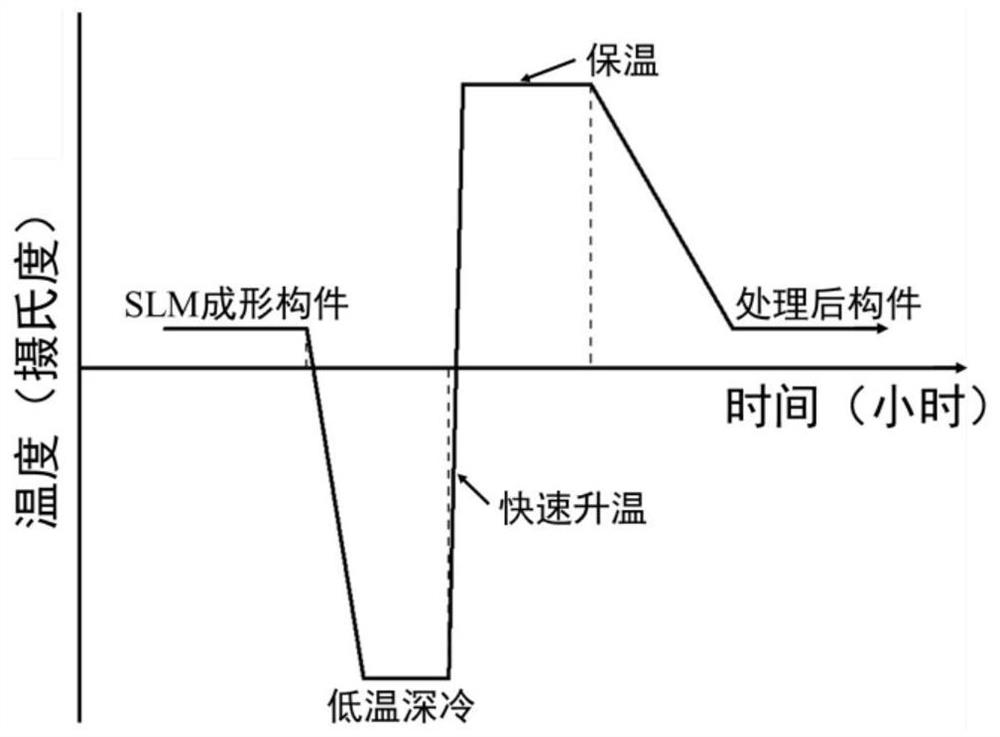

[0026] This embodiment provides a method for eliminating residual stress of an aluminum alloy component formed by selective laser melting. In the method, a schematic diagram of the temperature of the component changing with time figure 1 shown; the specific steps are:

[0027] (S1) AlSi10Mg alloy components formed by selective laser melting are immersed in liquid nitrogen for 30 min;

[0028] (S2) the component is quickly transferred to 180 ℃ of dimethicone oil, so that it is rapidly heated up, and kept for 30min;

[0029] (S3) The take-out member is cooled to room temperature in the air.

[0030] Wherein, the transfer time in step S2 is 3s, and the average heating rate in this process is 52°C / min.

[0031] X-ray stress analyzer (equipment model: iXRD) was used to test the residual stress of the AlSi10Mg alloy components formed by selective laser melting before and after treatment. The stress is reduced to 36±4MPa.

Embodiment 2

[0033] The present embodiment provides a method for eliminating residual stress of an aluminum alloy component formed by selective laser melting. The specific steps are:

[0034] (S1) AlSi10Mg alloy components formed by selective laser melting are immersed in liquid nitrogen for 30 min;

[0035] (S2) the component is quickly transferred to 150 ℃ of dimethyl silicone oil, so that it is rapidly heated up, and kept for 30min;

[0036] (S3) take out the member and cool it to room temperature in air;

[0037] (S4) Repeat operations S1-S3 once.

[0038] Wherein, the transfer time in step S2 is 3s, and the average heating rate in this process is 38°C / min.

[0039] X-ray stress analyzer (equipment model: iXRD) was used to test the residual stress of the AlSi10Mg alloy components formed by selective laser melting before and after treatment. The stress is reduced to 10±3MPa.

Embodiment 3

[0041] The present embodiment provides a method for eliminating residual stress of an aluminum alloy component formed by selective laser melting. The specific steps are:

[0042] (S1) AlSi10Mg alloy components formed by selective laser melting are immersed in liquid nitrogen for 30 min;

[0043] (S2) quickly transfer this component to 150 ℃ of dimethyl silicone oil, make it heat up rapidly, and keep warm for 10min;

[0044] (S3) take out the member and cool it to room temperature in air;

[0045] (S4) Repeat operations S1-S3 twice.

[0046] Wherein, the transfer time in step S2 is 3s, and the average heating rate in this process is 36°C / min.

[0047] X-ray stress analyzer (equipment model: iXRD) was used to test the residual stress of the AlSi10Mg alloy components formed by selective laser melting before and after treatment. The stress is reduced to 26±4MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com